Professional Premium Aluminum Oxide Products Supplier

1. Production Process of Alumina Ceramic Catalyst Supports

1.1 Raw Material Processing and Forming

Manufacturing begins with selecting high-purity aluminum precursors like gibbsite (Al(OH)₃) or boehmite (AlOOH). These undergo calcination at 400-600°C to form transition aluminas with controlled reactivity. The powder is then mixed with organic binders and pore-forming agents before extrusion, pelletization, or pressing into desired shapes. For honeycomb structures, plasticized alumina paste is extruded through diamond dies to create monolithic structures with precise channel geometries. Spherical supports utilize oil-drop granulation, where alumina sol droplets solidify in hot oil baths. Critical parameters like particle size distribution (typically 1-10 μm) and binder content determine green body strength and final porosity.

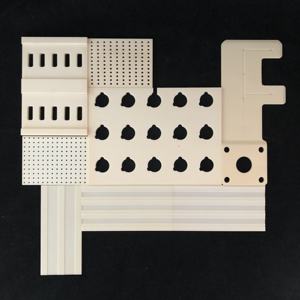

(Alumina Ceramic Chemical Catalyst Supports)

1.2 Structural and Performance Benefits

The engineered microstructure delivers critical functional advantages. Controlled surface area (typically 150-350 m²/g) provides abundant active sites for catalyst dispersion. Pore volume distribution facilitates optimal reactant flow and mass transfer efficiency. Unlike metallic alternatives, alumina’s dielectric properties prevent unwanted electrical interactions in reactive systems. The material’s low thermal expansion coefficient (8.1×10⁻⁶/K) minimizes thermal stress cracking during temperature cycling. These characteristics combine to enhance catalytic activity, improve selectivity, and reduce pressure drops in reactor systems. The ceramic’s high crush strength (>200 MPa) ensures physical durability under mechanical loads, maintaining performance in fixed-bed and fluidized-bed reactors.

2. What Are Alumina Ceramic Chemical Catalyst Supports?

2.1 Fundamental Composition and Structure

Alumina ceramic catalyst supports are porous, high-purity aluminum oxide structures engineered to carry active catalytic substances. Typically composed of 92-99.8% Al₂O₃, they function as physical substrates that increase reactive surface area while providing thermal and chemical stability. These supports exist in various forms including spheres, pellets, rings, and monolithic honeycombs, with surface areas ranging from 50 to 400 m²/g depending on phase composition. The γ-alumina phase is particularly valued for its mesoporous structure (2-50 nm pores), while θ and α phases offer greater thermal stability. Unlike the catalyst itself, the support doesn’t participate directly in reactions but significantly influences activity through surface chemistry, pore architecture, and thermal management.

2.2 Functional Roles in Catalysis

These supports perform multiple critical functions beyond mere physical hosting. They disperse active components (like platinum or palladium) to maximize catalytic surface exposure and prevent agglomeration. The porous network facilitates efficient reactant diffusion to active sites while enabling rapid product egress. During exothermic reactions, alumina’s thermal conductivity dissipates heat to prevent hotspot formation and thermal runaway. The material also protects active catalysts from sintering and chemical poisoning. In automotive converters, alumina washcoats on ceramic monoliths provide the foundational structure for three-way catalysts. Their electrical insulation properties prevent unwanted side reactions in electrochemical processes, making them indispensable across chemical manufacturing sectors.

3. Production Process of Alumina Ceramic Catalyst Supports

3.1 Raw Material Processing and Forming

Manufacturing begins with selecting high-purity aluminum precursors like gibbsite (Al(OH)₃) or boehmite (AlOOH). These undergo calcination at 400-600°C to form transition aluminas with controlled reactivity. The powder is then mixed with organic binders and pore-forming agents before extrusion, pelletization, or pressing into desired shapes. For honeycomb structures, plasticized alumina paste is extruded through diamond dies to create monolithic structures with precise channel geometries. Spherical supports utilize oil-drop granulation, where alumina sol droplets solidify in hot oil baths. Critical parameters like particle size distribution (typically 1-10 μm) and binder content determine green body strength and final porosity.

3.2 Sintering and Surface Modification

The formed “green” bodies undergo controlled thermal treatment in kilns at 1200-1600°C. This sintering process densifies the structure while developing the desired crystalline phase and pore architecture. Temperature profiles precisely control the transition from γ to α-alumina phases, with dwell times determining final porosity and surface area. Post-sintering, supports often receive surface treatments like acid washing to optimize hydroxyl group concentration for better catalyst adhesion. Advanced modifications include chemical etching to increase surface roughness or secondary coating with stabilizers like lanthanum oxide to prevent phase transitions during operation. Quality verification includes crush testing, mercury porosimetry, and BET surface area analysis before catalyst impregnation.

4. Application Fields of Alumina Ceramic Catalyst Supports

4.1 Petroleum and Chemical Processing

In petroleum refining, alumina supports are fundamental to hydrodesulfurization (HDS) units where they carry molybdenum-cobalt catalysts to remove sulfur from crude oil. Fluid catalytic cracking (FCC) utilizes alumina-based zeolite composites to break heavy hydrocarbons into gasoline. The chemical industry employs them in steam reforming reactors for hydrogen production, where their thermal stability maintains nickel catalyst dispersion at 800°C. They’re essential in olefin production through dehydrogenation processes, providing acid sites for selective reactions. Ammonia synthesis employs iron catalysts on alumina promoters to enhance efficiency. Their chemical inertness makes them ideal for chlorination processes where metal supports would corrode.

4.2 Environmental and Specialty Applications

Automotive exhaust systems rely on alumina-washcoated ceramic monoliths as substrates for three-way catalysts that convert CO, NOx, and hydrocarbons. Industrial catalytic oxidizers use alumina-supported precious metals to destroy volatile organic compounds (VOCs). In wastewater treatment, they support photocatalytic TiO₂ for advanced oxidation processes. The pharmaceutical industry utilizes them in selective hydrogenation of fine chemicals. Emerging applications include biomass conversion for sustainable fuels and carbon capture systems where functionalized alumina supports adsorb CO₂. Specialty uses extend to fuel cell electrodes and hydrogen storage materials, leveraging their nanoscale tunability.

5. Selection Criteria for Quality Alumina Catalyst Supports

5.1 Performance-Based Parameters

Select optimal supports by evaluating pore size distribution using mercury intrusion porosimetry—mesoporous (2-50nm) structures suit most vapor-phase reactions, while macropores (>50nm) benefit high-throughput liquid processes. Verify specific surface area via BET analysis; 150-300 m²/g balances active site density with structural stability. Assess crush strength (>200N per sphere) and attrition resistance through ASTM testing, especially for fluidized beds. Confirm phase composition via XRD—γ-alumina offers maximum surface area, while α-phase provides superior thermal durability. Validate chemical purity (≥99% Al₂O₃) to prevent catalyst poisoning by trace metals like sodium or iron.

5.2 Application-Specific Considerations

For high-temperature processes (>800°C), prioritize phase-stabilized supports with lanthanum or silica additives to prevent θ→α transition and surface area loss. In corrosive environments, specify low-soda alumina (<0.05% Na₂O) to enhance acid resistance. Select monolithic structures for low-pressure-drop applications like automotive converters, but choose spherical pellets for fixed-bed reactors requiring optimal packing density. For exothermic reactions, verify thermal conductivity measurements to ensure efficient heat dissipation. Always request customizable geometry—channel density in monoliths (400-1200 CPSI) or pellet diameter (1-10mm) should match reactor design. Partner with suppliers offering surface modification services like chlorination or peptization to enhance catalyst adhesion.

6. Frequently Asked Questions About Alumina Catalyst Supports

6.1 Stability and Compatibility Concerns

Q: How do alumina supports withstand thermal cycling?

A: Advanced formulations incorporate phase stabilizers (e.g., La₂O₃, SiO₂) that inhibit destructive γ→α transformation during thermal cycling. The ceramic’s low thermal expansion coefficient minimizes stress fractures. Typical industrial grades endure >10,000 cycles between 200-900°C. Q: Are alumina supports compatible with strong acids/alkalis?

A: While highly resistant to organic acids and weak alkalis, concentrated mineral acids (especially HF) and strong caustics (≥40% NaOH) can dissolve alumina. For such environments, surface-passivated grades or zirconia-modified composites are recommended.

6.2 Performance Optimization Questions

Q: What determines optimal pore size for specific reactions?

A: Pore geometry must match molecular kinetics: Reactions with large molecules (e.g., hydroprocessing heavy crude) require >50nm macropores to prevent diffusion limitations, while gas-phase reactions with small molecules (e.g., CO oxidation) benefit from 5-20nm mesopores maximizing surface area. Q: Can spent alumina supports be regenerated?

A: Yes, controlled calcination at 500°C oxidizes carbon deposits, while acid washing removes metal contaminants. However, repeated regeneration causes gradual surface area loss. High-quality supports typically withstand 3-7 regeneration cycles before replacement.

(Alumina Ceramic Chemical Catalyst Supports)

Tags: alumina catalyst carrier, ceramic catalyst support, activated alumina balls, alumina catalyst substrate, porous ceramic support, alumina catalyst media, industrial catalyst support, ceramic honeycomb catalyst

Supplier

Alumina Technology Co., Ltd focus on the research and development, production and sales of aluminum oxide powder, aluminum oxide products, aluminum oxide crucible, etc., serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services. If you are looking for high quality Alumina Ceramic Products , please feel free to contact us. (nanotrun@yahoo.com)