Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

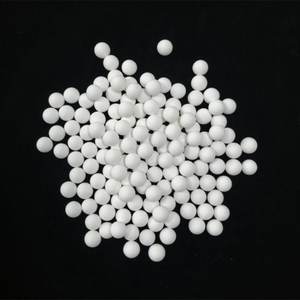

Overview of 92 High Purity Alumina Ceramic Balls High Aluminum Refractory Ball for Oven Kiln Furnace

Alumina balls are high-purity ceramic grinding media known for their exceptional hardness, wear resistance, and thermal stability. Ideal for industrial applications like milling, catalysis, and wear-resistant components.

Features of 92 High Purity Alumina Ceramic Balls High Aluminum Refractory Ball for Oven Kiln Furnace

High mechanical strength & durability

Excellent chemical & thermal stability

Superior wear & corrosion resistance

Available in various sizes & purity grades

Low contamination for precision processes

(92 High Purity Alumina Ceramic Balls High Aluminum Refractory Ball for Oven Kiln Furnace)

Specification of 92 High Purity Alumina Ceramic Balls High Aluminum Refractory Ball for Oven Kiln Furnace

These 92% high purity alumina ceramic balls deliver severe performance in hot settings. They are constructed from costs products. This provides impressive heat resistance. They deal with temperature levels as much as 1700 ° C easily. This makes them excellent for requiring tasks inside kilns, stoves, and industrial heaters.

The high light weight aluminum oxide content is vital. It ensures the balls remain extremely solid even under extreme heat. They stand up to thermal shock well. This indicates they won’t split or break easily when temperatures alter quickly. This reliability is crucial for continuous heater procedure. Downtime is pricey.

These balls are extremely dense and tough. Their surface is smooth. This combination lowers damage dramatically. They last a lot longer than cheaper alternatives. You conserve money with time because you replace them less usually. Their chemical security is excellent as well. They resist attack from many corrosive gases and molten materials located in heating system environments. This keeps their form and function intact.

Use them as inert bed support media. They hold stimulant pellets or various other materials stable in high-temperature procedures. Their round shape and uniform dimension make certain also gas or fluid flow. This advertises much better heat distribution and extra reliable reactions inside your heater. They assist enhance your process. Regular efficiency issues.

These refractory rounds are constructed challenging. They endure severe conditions every day. Their high purity alumina building and construction gives dependable thermal and mechanical stability. This translates directly to enhanced heating system efficiency and lower operating costs.

(92 High Purity Alumina Ceramic Balls High Aluminum Refractory Ball for Oven Kiln Furnace)

Applications of 92 High Purity Alumina Ceramic Balls High Aluminum Refractory Ball for Oven Kiln Furnace

These 92% high pureness alumina ceramic spheres are difficult. They are created requiring warm. Ovens, kilns, and furnaces require reliable parts. These rounds supply. They deal with extreme temperature levels quickly. This is vital for high-heat areas. Sudden temperature level modifications happen often. Thermal shock cracks weak materials. These balls stand up to that. They stay solid.

Chemical strike is another problem. Fumes and liquified products exist inside furnaces. These spheres won’t respond quickly. They keep their form and strength. Abrasion wears points down fast. Materials relocate regularly inside devices. These rounds are extremely hard. They stand up to put on much longer than less expensive choices. You save cash with time.

Where do you utilize them? Stimulant support beds are one major area. Drivers need stable platforms. These rounds offer that stability under heat and stress. Grinding and grating demand challenging media. These spheres wreck and blend materials without damaging down. They are ideal for grinding difficult powders.

Insulation layers likewise benefit. These spheres pack together. They produce obstacles against warm loss. Power efficiency boosts. Heating system cellular linings take consistent misuse. Using these balls prolongs the liner life. Upkeep prices decrease. Steel heat therapy requires precise problems. These spheres aid keep also temperature levels. They do not contaminate the procedure.

Gas distribution needs even move. These balls act as packing product. They guarantee gases spread out effectively with activators. Strength issues under hefty lots. These spheres support weight without squashing. They are reputable.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 92 High Purity Alumina Ceramic Balls High Aluminum Refractory Ball for Oven Kiln Furnace

Here are 5 FAQs about 92 High Purity Alumina Ceramic Balls:

What are these balls made of?

They are made from high purity alumina ceramic. The alumina content is 92%. This makes them very strong and resistant to heat. They are designed for tough industrial use.

What sizes can I get?

These balls come in many different sizes. Common diameters are 10mm, 15mm, 20mm, 25mm, and 30mm. Other sizes are also possible. Ask about your specific size needs.

How hot can they get?

They handle very high temperatures well. They work reliably up to 1650°C (about 3000°F). This makes them perfect for ovens, kilns, and furnaces. They won’t crack easily under heat stress.

Will chemicals damage them?

No, they resist most chemicals very well. Acids and alkalis won’t harm them much. They also resist corrosion. This makes them good for harsh chemical environments. They stay stable.

How long do they last?

They last a very long time. Their high hardness and density prevent wear. They resist cracking and chipping. This means less downtime for replacement. They are a cost-effective solution over time.

(92 High Purity Alumina Ceramic Balls High Aluminum Refractory Ball for Oven Kiln Furnace)

REQUEST A QUOTE

RELATED PRODUCTS

Industrial Wear-Resistant Alumina Ceramic Ball Media White Inert Ceramic Alumina Processing Services Welding Cutting Bending

Whole Wear-resistant 7mm 9/32inch 7.5mm 5/16inch Alumina Ball/Ceramic Ball for Bicycle Part

6.4mm-100mm G3-G200 Ceramic Balls Aluminum Oxide Balls Al2o3 Balls for Bearings 92%, 95%,99% and Above Alumina

92% 95% Alumina Ceramic Balls for Grinding

Custom High Alumina Ceramic Ball 3mm 12mm 25mm 92% Alumina Grinding Media Porcelain Balls