Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

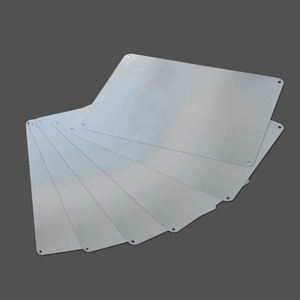

Overview of Alumina Ceramic Radiator / Ceramic Custom High Temperature Ceramic Plate

Alumina Ceramic Radiator / Ceramic Custom High Temperature Ceramic Plate is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of Alumina Ceramic Radiator / Ceramic Custom High Temperature Ceramic Plate

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(Alumina Ceramic Radiator / Ceramic Custom High Temperature Ceramic Plate)

Specification of Alumina Ceramic Radiator / Ceramic Custom High Temperature Ceramic Plate

Alumina ceramic radiators take care of heat effectively. They are made from pure light weight aluminum oxide ceramic. This material handles extreme temperature levels quickly. It functions fine over 1600 ° C. This makes it excellent for high warmth scenarios. These ceramic plates are excellent electric insulators. They quit power from streaming via them. This is important for safety and performance. Heat relocations via the alumina ceramic effectively. It spreads out warmth out quickly. This quits hot spots from creating. The ceramic is extremely strong. It stands up to scrapes and use. It lasts a very long time despite heavy usage. Chemicals do not damage it easily. It withstands corrosion from acids and alkalis. We make these ceramic plates to your specific demands. You select the density. You select the size. You choose the shape. We can cut holes. We can add grooves. We can develop unique attributes. This guarantees the plate fits completely in your tool. Alumina ceramic is stable. It does not change dimension much with temperature. This keeps things exact throughout heating and cooling. It is additionally very stiff. It does not flex or flex under stress. This maintains its shape under load. The surface area is really smooth. You can polish it extra if required. This helps with heat transfer. It also makes cleaning simple. These plates prepare to utilize. They mount conveniently right into heating unit. They supply reliable insulation. They provide outstanding thermal monitoring. They take care of challenging conditions without failing. They are a trustworthy service for demanding applications. They need almost no maintenance.

(Alumina Ceramic Radiator / Ceramic Custom High Temperature Ceramic Plate)

Applications of Alumina Ceramic Radiator / Ceramic Custom High Temperature Ceramic Plate

Alumina ceramic radiators deal with extreme warmth well. They transfer warmth effectively far from sensitive electronic devices. Several electronics require this cooling. These radiators work in challenging places. They take care of high power without failing. Alumina ceramic plates are personalized made for details work. Factories use them under extreme warm. They hold parts throughout handling. Heaters use them as cellular linings. They stand up to chemical damage as well. This makes them last longer. Alumina ceramic stays strong at very high temperatures. Metals frequently compromise or thaw then. This ceramic maintains its form. It shields electrically extremely well. This protects against unsafe shorts. It is critical for power systems. The material is very hard. It stands up to scrapes and wear. This benefits relocating parts. Alumina ceramic does not rust conveniently. Extreme chemicals rarely affect it. This matches chemical plants well. Aerospace makes use of these porcelains. Jet engines have severe warmth areas. Alumina parts make it through there. They are lighter than metals. This helps save gas. Medical gadgets need tidy, strong materials. Alumina ceramic fits below. It operates in sterilizing tools. Semiconductor manufacturing demands purity. Alumina ceramic plates give it. They deal with the heat and chemicals. Custom forms are feasible. Engineers style plates for specific demands. This resolves challenging warmth problems. Manufacturing facilities obtain trusted performance. Assembly line maintain running efficiently. Nuclear power plant make use of these ceramics. They protect high voltage equipment. Security enhances with them. Alumina ceramic radiators cool LED lights. This extends their life. Industrial heating units make use of alumina plates. They distribute heat equally. This boosts product quality. Laboratories utilize custom plates. They support experiments requiring high warmth. Alumina ceramic deals a practical solution. It takes on requiring thermal difficulties dependably.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Alumina Ceramic Radiator / Ceramic Custom High Temperature Ceramic Plate

What is the highest temperature alumina ceramic plates handle?

Alumina ceramic plates handle extreme heat well. They work fine up to 1650°C (3000°F). This makes them much better than metals or plastics in very hot places. They won’t melt or break down easily.

Do these ceramic plates transfer heat effectively?

Yes, they transfer heat well. Alumina ceramic has good thermal conductivity. Heat moves through the plate efficiently. This is important for radiators needing to spread heat fast. It helps parts cool down or stay at the right temperature.

Where are these high-temperature ceramic plates used?

They are used in many tough jobs. Common uses are inside furnaces, kilns, and high-power electronics. They work in semiconductor tools, laser systems, and aerospace parts. Any place needing heat resistance and insulation uses them.

Can you get custom shapes and sizes?

Yes, you can order custom plates. Manufacturers make them in many shapes, thicknesses, and hole patterns. Tell them your exact needs. They cut and finish the ceramic to fit your machine or process perfectly.

Why choose alumina ceramic over cheaper materials?

Alumina ceramic costs more upfront. But it saves money later. It lasts long in extreme heat where metals fail. It resists corrosion and wear. You won’t replace it often. Its performance and reliability justify the higher cost for critical uses.

(Alumina Ceramic Radiator / Ceramic Custom High Temperature Ceramic Plate)

REQUEST A QUOTE

RELATED PRODUCTS

60x48x0.5mm Ceramic substrate disc plate tile alumina 99.99%

Hard Panel III IV Ceramic Plate Alumina Silicon Carbide PE BR5 Impact Surface Armor Deck Tactical Personal Defense Equipment

95 Alumina Ceramic Plates Porous Ceramic Plates OEM Supply

wear panels \ Professional Custom Wear-resistant 95 Alumina Ceramic & Rubber Composite Plate

Aluminium Oxide Circular White Round Block Alumina Ceramic Plate