Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

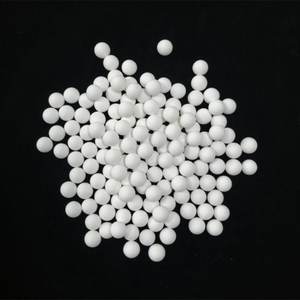

Overview of High Temperature Resistant Alumina Grinding Ball, Suitable for Fine Grinding of Various Heat Treated Materials

Alumina balls are high-purity ceramic grinding media known for their exceptional hardness, wear resistance, and thermal stability. Ideal for industrial applications like milling, catalysis, and wear-resistant components.

Features of High Temperature Resistant Alumina Grinding Ball, Suitable for Fine Grinding of Various Heat Treated Materials

High mechanical strength & durability

Excellent chemical & thermal stability

Superior wear & corrosion resistance

Available in various sizes & purity grades

Low contamination for precision processes

(High Temperature Resistant Alumina Grinding Ball, Suitable for Fine Grinding of Various Heat Treated Materials)

Specification of High Temperature Resistant Alumina Grinding Ball, Suitable for Fine Grinding of Various Heat Treated Materials

These alumina grinding rounds handle extreme warmth. They are best for grinding challenging, heat-treated materials carefully. Heats are not a problem for them. They keep working well when various other products might fail.

The rounds are made from costs alumina. This provides exceptional hardness. They withstand put on better than ordinary grinding media. You get longer service life. This means fewer substitutes. You conserve cash in time.

Their density is high. This provides strong grinding force. It damages down products successfully. You attain finer bit sizes constantly. This is essential for quality control.

Chemical stability is one more crucial feature. The balls won’t react with a lot of products. Your product remains pure. Contamination dangers are low. This is vital for sensitive applications.

These balls keep their shape under stress. They stand up to splitting and chipping. Your grinding process remains secure. Outcomes are foreseeable set after set. You stay clear of unexpected downtime.

They work well in several grinding machines. Ball mills and attritors are common examples. The balls fit various sectors. Ceramics, electronics, and advanced materials advantage. Anywhere great grinding of hard, heat-treated stuff is needed.

Utilizing them boosts grinding effectiveness. Less energy is needed for the same result. Your operating expense reduce. Product high quality commonly improves too. The constant dimension and purity aid a whole lot.

(High Temperature Resistant Alumina Grinding Ball, Suitable for Fine Grinding of Various Heat Treated Materials)

Applications of High Temperature Resistant Alumina Grinding Ball, Suitable for Fine Grinding of Various Heat Treated Materials

These high temperature alumina grinding spheres take care of intense warm. They function reliably in grinding mills where temperatures obtain very high. They withstand temperatures approximately around 1700 ° C. This makes them excellent for grinding materials that have actually been heat dealt with. These materials are frequently very difficult and rough.

The balls themselves are incredibly difficult and wear-resistant. They stay hard also at high temperatures. This firmness is vital for fine grinding. It enables the rounds to crush products into really little, constant fragments. You get the fine particle dimension you need. They likewise withstand chemical strike well. They won’t contaminate your sensitive heat-treated products.

Several sectors use these balls. They grind heat-treated ceramics successfully. These ceramics are tough after shooting. The balls grind sintered metal powders successfully. These powders end up being hard after sintering. They function well for grinding heat-treated tool steels. These steels are hardened for sturdiness. They additionally grind specialized glass batches needing heats.

Making use of these rounds enhances your grinding procedure. They last a lot longer than standard grinding rounds under warmth. You change them less typically. This saves you money on materials. It additionally indicates less downtime for maintenance. You get more constant grinding results. The particle size circulation stays secure. This results in better top quality in your final product. They assist preserve a pure grinding atmosphere. Contamination dangers are reduced.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Temperature Resistant Alumina Grinding Ball, Suitable for Fine Grinding of Various Heat Treated Materials

What are high temperature resistant alumina grinding balls?

These are special grinding balls made from alumina ceramic. They are designed to withstand very high heat. They are used in mills to grind materials down to a fine powder. They are especially good for grinding materials that have been heat treated.

Why is high temperature resistance important for grinding balls?

Many grinding processes generate a lot of heat. Regular grinding balls can weaken or crack under high temperatures. These alumina balls stay strong even when things get very hot. This means they keep grinding effectively. They don’t break down easily under thermal stress. You get consistent grinding results.

What kinds of materials are these balls good for grinding?

They are excellent for grinding heat-treated metals and alloys. Think of hardened steel or tempered metals. They also work well for grinding ceramics that have been fired. Other materials like certain minerals processed with heat are suitable too. Basically, they are ideal for any tough material that has undergone heat treatment.

How does using these balls benefit my grinding process?

They last much longer than regular balls when grinding hot, hard materials. Because they resist wear so well, you replace them less often. This saves you money on media costs. They also help maintain a stable grinding environment. Consistent particle size is easier to achieve. Less ball wear means less contamination in your final product.

What sizes of these alumina grinding balls are available?

Manufacturers offer these balls in different diameters. Common sizes range from just a few millimeters up to around 50 millimeters. The right size depends on your mill and the starting size of your material. You need the correct size for efficient grinding. Smaller balls are better for very fine grinding results.

(High Temperature Resistant Alumina Grinding Ball, Suitable for Fine Grinding of Various Heat Treated Materials)

REQUEST A QUOTE

RELATED PRODUCTS

94.6% 0.1-50mm Zirconia/ZrO2 Ceramic Balls High Strength Grinding Media Alumina Beads For Industry Milling

High Density 3mm 6mm 10mm Support Media 17-19% Alumina Ceramic Balls for Hydroprocessing Application

High-Density Al2O3 Alumina Grinding Ball Industrial Ceramic Media for Efficient Grinding

Industrial Wear-Resistant Alumina Ceramic Ball Media White Inert Ceramic Alumina Processing Services Welding Cutting Bending

Ceramics 99% 95%Alumina Grinding Ball 0.5-120mm Creamic Ball Alumina Ceramic Sintered Bead Diameter