Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

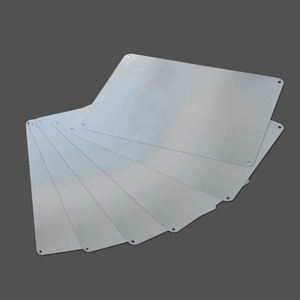

Overview of Tabular Alumina Aluminium Oxide Plate Shaped Corundum Fine Powder for Electronic Ceramic Semiconductor Device Block Pattern

Tabular Alumina Aluminium Oxide Plate Shaped Corundum Fine Powder for Electronic Ceramic Semiconductor Device Block Pattern is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of Tabular Alumina Aluminium Oxide Plate Shaped Corundum Fine Powder for Electronic Ceramic Semiconductor Device Block Pattern

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(Tabular Alumina Aluminium Oxide Plate Shaped Corundum Fine Powder for Electronic Ceramic Semiconductor Device Block Pattern)

Specification of Tabular Alumina Aluminium Oxide Plate Shaped Corundum Fine Powder for Electronic Ceramic Semiconductor Device Block Pattern

This Tabular Alumina powder is aluminium oxide. It’s really pure Al2O3. We make it for electronic ceramics. Semiconductors use it as well. The powder has a special shape. It’s plate-like corundum crystals. This shape matters a lot. It aids the bits compact securely. Limited packing benefits making solid blocks. The fine powder dimension is regulated thoroughly. We make sure the particles are small and consistent. Consistent dimension aids with smooth flow. Great circulation is required for loading molds uniformly. This is crucial for making precise patterns. Tool block patterns require sharp information. This powder aids achieve that intensity.

High purity is necessary here. Pollutants create problems. They can wreck electrical buildings. They can weaken the ceramic framework. Our powder has exceptionally reduced contaminations. Sodium and silica degrees are very reduced. Iron and other metals are additionally very little. This purity makes certain stable performance. Digital tools need integrity. Pure alumina offers that dependability.

The plate-shaped particles offer advantages. They improve the green toughness of unfired components. Components manage far better prior to sintering. They likewise assist the sintering procedure itself. Sintering makes the ceramic dense and difficult. Plate-like grains aid densification take place better. This brings about a finer, more powerful final microstructure. Strong ceramics last much longer. They withstand splitting and put on.

You utilize this powder in pushing or casting. It forms complex block patterns. These patterns are part of semiconductor tools. The great particle size catches complex details. Details are vital for modern electronics. The powder moves well into mold and mildew dental caries. It leaves no gaps or weak spots. The final fired ceramic has high thickness. It has exceptional electric insulation. It stands up to warm and chemicals extremely well. These properties safeguard sensitive digital elements.

(Tabular Alumina Aluminium Oxide Plate Shaped Corundum Fine Powder for Electronic Ceramic Semiconductor Device Block Pattern)

Applications of Tabular Alumina Aluminium Oxide Plate Shaped Corundum Fine Powder for Electronic Ceramic Semiconductor Device Block Pattern

Tabular alumina is aluminum oxide plate shaped diamond great powder. This product issues for digital ceramic semiconductor tools. Its plate like crystal structure offers special properties. This alumina powder is very pure. It has reduced salt content. That purity is important for electronics. Impurities cause problems in semiconductor processes.

Manufacturers utilize this alumina in ceramic substratums. These substratums hold digital circuits. Home plate shaped grains load tightly with each other. This packing produces solid, thick porcelains. The porcelains manage heats well. They stand up to thermal shock. Electronics fume throughout use. These ceramics stay stable. They are superb electric insulators too. Circuits need great insulation.

This alumina powder is vital for semiconductor device obstructs. These blocks form core components of chips. The powder sinters uniformly. Sintering means heating up to bond bits. Uneven sintering creates warping or cracks. The plate shape aids particles align. Positioning stops irregular diminishing. Blocks remain flat and accurate. Precision is non-negotiable in semiconductors. Tiny abandons ruin gadget performance.

The fine powder size permits comprehensive patterns. Engineers produce intricate block layouts. The powder flows smoothly right into molds. It loads complex shapes completely. This leads to sharp, precise attributes. Fine attributes are necessary for modern-day electronic devices. Devices keep getting smaller. Material uniformity guarantees every block matches. Uniformity is vital for automation.

This alumina additionally makes thin ceramic layers. These layers separate different components of a device. They give insulation and assistance. The plate grains secure with each other. This produces hard, reliable barriers. Gadget last longer and fail less usually. Reliability matters in every little thing from phones to cars and trucks.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Tabular Alumina Aluminium Oxide Plate Shaped Corundum Fine Powder for Electronic Ceramic Semiconductor Device Block Pattern

What is Tabular Alumina? Tabular Alumina is a special type of aluminium oxide. It is made by sintering calcined alumina at very high temperatures. This process creates large, flat crystals. These crystals are very strong and stable. The result is a pure, high-density material. It is excellent for demanding technical uses.

Why is the plate-like particle shape important? The plate shape is key. These flat particles stack together tightly. They create a dense structure. This structure resists cracking under stress. It handles heat very well. This shape also helps control how liquids flow in ceramic mixes. It makes the final ceramic product stronger and more reliable.

What are the main benefits in electronic ceramics? Tabular Alumina brings several big advantages. It offers outstanding thermal stability. It handles high temperatures without breaking down. Its chemical purity prevents contamination. This is vital for semiconductors. It provides excellent electrical insulation. It resists wear extremely well. Its controlled particle size ensures consistent performance. This makes devices more dependable.

Where is it used in electronic devices? You find it in many critical electronic parts. It is used in ceramic substrates for circuits. It is used in insulating layers for semiconductor packages. It is used in components for sensors. It is used in parts for high-frequency devices. It is used in blocks needing precise patterns. Its stability and purity are essential here. It ensures the device works correctly and lasts long.

Why is it called “tabular”? It gets the name “tabular” from its shape. The crystals look like small plates or tablets. This flat, plate-like structure is formed during the special sintering process. This shape is different from other alumina powders. This shape gives it its unique properties.

(Tabular Alumina Aluminium Oxide Plate Shaped Corundum Fine Powder for Electronic Ceramic Semiconductor Device Block Pattern)

REQUEST A QUOTE

RELATED PRODUCTS

High Purity Alumina Bulletproof Plate Ceramic Plate

Thickness 0.635mm to 1mm 99% Al2o3 Alumina Ceramic Plate Substrate

Al2O3 Alumina Ceramic Plates Sheet 95-99% Aluminum Oxide for Structure Ceramic Burner

High Quality 99% Alumina Ceramic Plate Al2O3 Ceramic Sheet

High Purity Alumina Ceramic Slide Block Plate Alumina Ceramic Part Slot Block