Professional Premium Aluminum Oxide Products Supplier

1. Introduction

When you hear ‘alumina ceramic baking dish,’ your mind might jump to holiday casseroles or artisanal dinnerware. But beyond the kitchen, this material is quietly transforming high-stakes scientific environments. In laboratories handling materials science, geochemistry, or metallurgy, the humble alumina ceramic baking dish serves as a workhorse for extreme thermal applications—thanks to its unmatched resistance to heat, corrosion, and contamination.

Unlike standard porcelain or glassware, alumina (Al₂O₃)-based ceramics can withstand temperatures exceeding 1,600°C without warping, cracking, or leaching impurities. This makes them indispensable for tasks like ashing organic samples, fusing silicates, or preparing ultra-pure melts for spectroscopic analysis.

2. Why Alumina Ceramic Excels in Lab Settings

2.1. Thermal and Chemical Resilience

Alumina ceramic baking dishes maintain structural integrity even under rapid thermal cycling—a common requirement in analytical protocols. They resist attack from acids, alkalis, and molten salts that would degrade quartz or borosilicate alternatives. This inertness ensures sample purity, a non-negotiable in trace-element analysis.

Moreover, their low thermal expansion coefficient minimizes stress fractures during heating and cooling. Whether you’re using an alumina ceramic casserole with lid for slow ramping or an open alumina oven ceramic dish for rapid ashing, reliability is built in.

2.2. Purity and Non-Contamination

High-purity (>99%) alumina contains minimal metallic impurities, preventing cross-contamination during high-temperature processing. This is critical when analyzing environmental samples, pharmaceuticals, or semiconductor-grade materials where even parts-per-billion interference can skew results.

In contrast, traditional ceramic labware may contain fluxes or colorants that volatilize at high temps. Alumina ceramic dishes for oven use eliminate this risk, functioning more like crucibles than cookware—though they share design similarities with items like alumina ceramic butter dish with lid or alumina ceramic serving bowls.

3. Real-World Laboratory Applications

3.1. Sample Ashing and Combustion Residue Collection

Environmental and food safety labs routinely use alumina ceramic baking dishes to ash biological or organic matrices. After combustion in a muffle furnace, the residue—free from dish-derived contaminants—is dissolved for ICP-MS or AAS analysis. The flat, wide geometry of an alumina ceramic casserole dish allows even heat distribution and easy scraping of residues.

3.2. Fusion Flux Preparation

Geochemists preparing rock samples often employ lithium metaborate or tetraborate fusion—a process requiring temperatures near 1,000°C. Alumina ceramic dishes resist flux corrosion far better than platinum or zirconia alternatives in certain chemistries. Their durability also supports reuse, reducing lab costs over time.

3.3. High-Temperature Drying and Pre-Firing

Ceramic engineers and materials scientists use alumina oven dish ceramic formats to pre-fire nanopowders or dry sol-gel precursors. The nonporous surface prevents particle adhesion, ensuring yield recovery. These dishes double as alumina ceramic melting dishes for low-melting-point alloys or glass frits.

4. Design Adaptations for Scientific Use

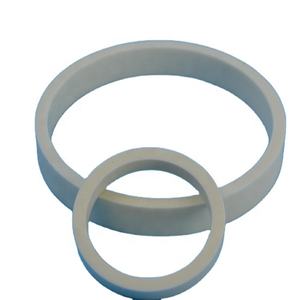

While commercial kitchen variants like alumina black ceramic plates or alumina white ceramic plates prioritize aesthetics, lab-grade alumina ceramic plates for dinner are repurposed for function. Many labs source custom shallow dishes resembling alumina ceramic salad bowls or alumina ceramic ramekins—but engineered for thermal shock resistance and dimensional stability.

Some institutions even use modified versions of alumina ceramic Christmas plates or alumina handcrafted ceramic plates as disposable sample trays during method development, thanks to their affordability and inertness compared to metal alternatives.

Crucially, these items share core properties with industrial alumina components like alumina ceramic tubes for high temperature or alumina crucibles—highlighting the material’s versatility across domains.

5. Practical Considerations for Lab Adoption

- Always verify alumina purity (99.5%+ is ideal for trace analysis).

- Avoid thermal shock by preheating dishes gradually in the furnace.

- Clean with dilute nitric acid or ultrasonic baths—never abrasive scrubbers.

- Store separately from metal tools to prevent surface contamination.

Though not marketed as such, many suppliers of alumina ceramic dinner plates or alumina ceramic serving platter also offer lab-certified versions. Look for ISO or ASTM compliance when sourcing.

6. Conclusion

The alumina ceramic baking dish has transcended its culinary origins to become a quiet hero in advanced laboratories. Its fusion of thermal endurance, chemical neutrality, and mechanical stability makes it uniquely suited for high-precision sample preparation—proving that sometimes, the most powerful scientific tools wear the humblest disguises. Whether labeled as an alumina casserole ceramic dish or a specialized alumina ceramic disc for high-temp use, its role in ensuring analytical accuracy is undeniable.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Alumina. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.