Professional Premium Aluminum Oxide Products Supplier

1. Introduction

In the past 48 hours, a breakthrough at the National Institute of Standards and Technology (NIST) highlighted the critical role of high-purity alumina ceramic vessels in preparing ultra-trace metal samples for atomic spectroscopy. Researchers reported a 30% reduction in cross-contamination when using alumina ceramic baking dishes instead of traditional quartz or platinum containers—underscoring a quiet but significant shift in lab protocols worldwide.

Though many associate ‘alumina ceramic baking dish’ with gourmet cookware or holiday tableware like alumina ceramic christmas plates or alumina black ceramic plates, the material’s real power emerges in controlled, high-stakes environments far from the kitchen. This article dives into one of its most advanced—and underappreciated—applications: high-temperature laboratory sample preparation.

2. Why Alumina Ceramic?

Alumina (Al₂O₃) ceramic is prized for its exceptional thermal stability, withstanding temperatures up to 1,700°C without deforming. Unlike standard ceramics, high-purity alumina is chemically inert, non-porous, and resistant to acids, alkalis, and molten metals—making it ideal for handling reactive or ultra-sensitive substances.

In labs, even trace impurities can skew results. Alumina ceramic dishes—whether labeled as alumina baking ceramic dish, alumina oven ceramic dish, or alumina ceramic casserole—offer a contamination-free surface that doesn’t leach ions or absorb analytes. This reliability is why institutions like NIST and CERN specify alumina vessels for critical thermal treatments.

3. Real-World Lab Application: Ashing and Fusion

One key use is in ‘ashing’—the controlled incineration of organic samples to isolate inorganic residues for analysis. Traditional porcelain crucibles may contain silica or alkali metals that interfere with results. In contrast, an alumina ceramic crucible or alumina ceramic melting dish ensures purity.

Similarly, in fusion sample prep—where minerals are melted with fluxes like lithium tetraborate at 1,000°C+—alumina ceramic casserole with lid or alumina ceramic bowl plates provide unmatched durability. Their smooth, non-wetting surface prevents sample adhesion, enabling complete recovery.

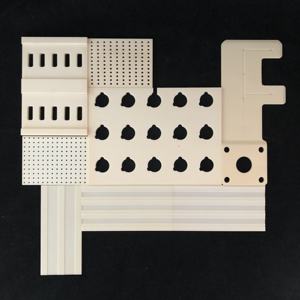

- Alumina ceramic ramekins are repurposed as micro-ashing vessels for forensic toxicology.

- Alumina ceramic serving bowls and alumina ceramic plate bowls serve as shallow evaporation dishes for solvent-free drying.

- Even alumina ceramic butter dish with lid finds use in storing hygroscopic reagents due to its hermetic seal and inertness.

4. Beyond the Beaker: Integration with Advanced Systems

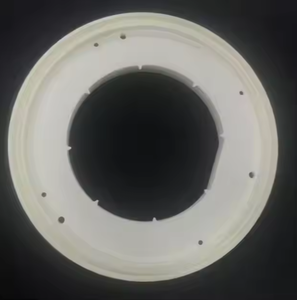

Modern labs increasingly pair alumina ceramic dishes with automated systems. For instance, alumina ceramic disc taps and alumina ceramic disk for tap components are used in high-temperature fluid handling, while alumina ceramic tubes—like alumina thermocouple protection tubes—work in tandem with alumina oven dish ceramic setups to monitor thermal profiles in real time.

Interestingly, the same manufacturing precision that creates alumina handcrafted ceramic plates for dinner also yields alumina ceramic plates for painting used in calibration standards. The material’s consistency allows for dual-use across art and science—a testament to its versatility.

5. Why Not Just Use Metal or Glass?

Platinum crucibles are expensive and can catalyze unwanted reactions. Quartz cracks under thermal shock. Stainless steel corrodes in acidic fluxes. Alumina ceramic dishes for oven use solve these issues: they’re cost-effective, reusable, and stable across extreme thermal cycles.

Moreover, unlike alumina ceramic dinner plates designed for aesthetics, lab-grade versions are engineered for performance—often featuring tighter dimensional tolerances, higher purity (>99.5% Al₂O₃), and certification for ISO/IEC 17025 compliance.

6. Emerging Trends and Future Outlook

With the rise of battery material research and rare-earth element recycling, demand for contamination-free high-temp vessels is surging. Companies are now offering custom alumina ceramic casserole dish configurations, including nested sets and lid-integrated designs inspired by kitchenware like alumina baking dish staub—but built for 1,600°C environments.

Even alumina ceramic childrens plates and alumina white ceramic plates share the same base material science, though lab versions skip glazes and pigments to maintain purity. This cross-pollination between consumer and industrial ceramics is accelerating innovation in both sectors.

7. Conclusion

The humble alumina ceramic baking dish is far more than a kitchen accessory. In advanced laboratories, it’s a silent guardian of data integrity—enabling precise, repeatable results in fields where a single contaminant can invalidate years of research. As science pushes toward ever-finer detection limits, the role of high-purity alumina ceramics will only grow, proving that sometimes, the most powerful tools look deceptively simple.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Alumina. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.