Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

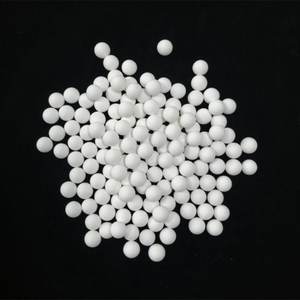

Overview of Refractory Material High-temperature and Heat-resistant Activated Alumina Hollow Ball Alumina Ceramic Balls Heat Insulation

Alumina balls are high-purity ceramic grinding media known for their exceptional hardness, wear resistance, and thermal stability. Ideal for industrial applications like milling, catalysis, and wear-resistant components.

Features of Refractory Material High-temperature and Heat-resistant Activated Alumina Hollow Ball Alumina Ceramic Balls Heat Insulation

High mechanical strength & durability

Excellent chemical & thermal stability

Superior wear & corrosion resistance

Available in various sizes & purity grades

Low contamination for precision processes

(Refractory Material High-temperature and Heat-resistant Activated Alumina Hollow Ball Alumina Ceramic Balls Heat Insulation)

Specification of Refractory Material High-temperature and Heat-resistant Activated Alumina Hollow Ball Alumina Ceramic Balls Heat Insulation

Here’s the product summary for refractory alumina hollow rounds:

Industrial heating systems require dependable insulation. Our high-temperature turned on alumina hollow rounds provide. These ceramic balls withstand severe warmth well. They endure temperature levels over 1800 ° C regularly. This makes them perfect for requiring kilns, reactors, and boilers.

The key is the hollow structure. Each round has an unique air-filled center. Air is a bad heat conductor. This trapped air creates a powerful thermal barrier. Warm does not pass through easily. Your heater stays hotter inside. Much less power escapes. You conserve considerable fuel costs.

These rounds are made from pure turned on alumina. Alumina is naturally tough and secure. It handles thermal shock effectively. Abrupt temperature adjustments won’t fracture them. They keep toughness also after repeated heating and cooling cycles.

They are incredibly light. This reduced bulk density decreases the tons on your heater framework. But do not blunder agility for weakness. The alumina ceramic material is solid. It stands up to abrasion and chemical deterioration from harsh heater atmospheres. This makes certain lengthy service life.

Installation is uncomplicated. Load the hollow balls into the shielding layer. They form a secure, efficient obstacle. Anticipate excellent warmth retention. Your procedure temperature control boosts. Operating costs lower since less energy is needed to keep high heat. They are a wise choice for high-efficiency thermal insulation in extreme atmospheres.

(Refractory Material High-temperature and Heat-resistant Activated Alumina Hollow Ball Alumina Ceramic Balls Heat Insulation)

Applications of Refractory Material High-temperature and Heat-resistant Activated Alumina Hollow Ball Alumina Ceramic Balls Heat Insulation

Activated alumina hollow round alumina ceramic spheres are special warm insulation materials. These balls are made from high pureness alumina. They go through special processing. This creates a hollow, spherical structure inside. The hollow framework is crucial. It offers the balls excellent heat insulation buildings. They trap warm very efficiently.

This product withstands very heats. It manages intense warm without breaking down. This makes it best for demanding industrial setups. Furnaces, kilns, and activators need dependable insulation. These spheres supply that. They maintain warmth inside the tools. This conserves substantial energy. Much less fuel is needed to keep high temperatures. Operating expenses reduce.

The hollow rounds are likewise very lightweight. This reduced weight is a significant benefit. Heavy insulation includes tension to structures. These spheres decrease that tons. Installment becomes simpler. Sustaining frameworks can be simpler and cheaper. The product shows great chemical stability also. It withstands assault from many harsh gases and liquified materials. This guarantees lengthy life span in harsh settings.

Thermal shock resistance is another strength. The spheres deal with rapid temperature level modifications well. Devices warms up and cools down regularly. Many materials crack under this stress. These alumina spheres maintain their integrity. They supply consistent efficiency gradually. Their low thermal conductivity is essential. It decreases warm escaping through furnace wall surfaces or reactor cellular linings. This directly boosts procedure effectiveness.

You discover these balls in many sectors. Steel plants use them in blast furnaces and ladles. Petrochemical facilities need them for radicals and crackers. Ceramic kilns and glass melting containers rely upon their insulation. Power generation boilers benefit too. They are essential any place heats and power savings matter. Their unique mix of heat resistance, reduced weight, and solid insulation solves difficult thermal monitoring troubles.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Refractory Material High-temperature and Heat-resistant Activated Alumina Hollow Ball Alumina Ceramic Balls Heat Insulation

What are activated alumina hollow balls?

These are special ceramic balls. They have tiny holes inside. They are made from aluminum oxide. This makes them very strong. They handle extreme heat well. People use them for insulation in hot places.

Why are they so lightweight?

The hollow center is key. It traps air inside. Air is very light. This cuts the weight dramatically. Less weight means easier installation. It also reduces stress on structures. You save money on support systems.

How do they insulate heat?

The trapped air inside the balls stops heat moving. Air is a poor heat conductor. The balls form a barrier. This barrier blocks heat transfer effectively. Your furnace or kiln stays hotter inside. Less heat escapes. This saves energy.

Where are they used?

They go into very hot industrial equipment. Think steel furnaces, petrochemical crackers, or ceramic kilns. They line the walls or roofs. They keep intense heat contained. They protect outer structures from damage. They are vital for high-temperature processes.

Can they handle sudden temperature changes?

Yes, they perform well. Activated alumina resists thermal shock. This means rapid heating or cooling won’t easily crack them. They stay stable. Their structure holds up. This reliability is important for industrial use. Equipment cycles on and off frequently.

(Refractory Material High-temperature and Heat-resistant Activated Alumina Hollow Ball Alumina Ceramic Balls Heat Insulation)

REQUEST A QUOTE

RELATED PRODUCTS

Hollow Ceramic Microspheres Oil Field Cementing Purpose Alumina Silicate Ball

Factory Zibo Grinding Media 92% Aluminum Oxide Al2O3 Alumina Ceramic Balls for Ball Mill

Alumina Foam Ceramic Ball

China Ceramic Ball Alumina Ceramic Refractory Balls

99.5% Al2O3 White Alumina Ceramic Balls for High Temperature and Corrosion Resistance 19.05mm EUR&USA