Professional Premium Aluminum Oxide Products Supplier

(High Purity 99% Alumina Ceramic Insulation Column Block Al2o3 Insulator Washer for Industrial)

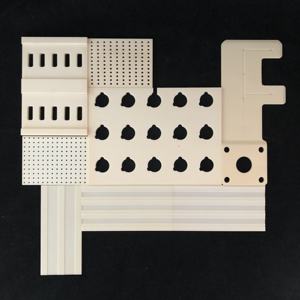

High Purity 99% Alumina Ceramic Insulation Column Block and Washer: Industrial Applications and Selection Guide

High-purity 99% alumina ceramic components serve as critical insulation solutions in demanding industrial environments. These precision-engineered parts leverage alumina’s exceptional material properties to deliver unmatched electrical insulation, thermal stability, and mechanical durability. This comprehensive guide examines their manufacturing processes, diverse industrial applications, key selection criteria, and answers common technical questions about these specialized components.

1. Why High Purity 99% Alumina Ceramic Insulation Components Exhibit Superior Characteristics

High-purity alumina ceramic (Al₂O₃) insulation column blocks and washers demonstrate exceptional performance characteristics stemming from their material composition. With 99% alumina content, these components achieve outstanding dielectric strength exceeding 15 kV/mm, making them ideal for high-voltage applications. Their extremely low thermal conductivity (approximately 30 W/m·K) ensures effective thermal isolation in high-temperature industrial processes reaching 1600°C.

The material’s exceptional hardness (9 on Mohs scale) provides superior wear resistance in abrasive environments, while the near-zero porosity of high-purity alumina prevents gas permeation and maintains structural integrity under vacuum conditions. Unlike polymer-based insulators, alumina ceramics exhibit excellent radiation resistance and won’t degrade under UV exposure. These properties, combined with outstanding chemical inertness against acids and alkalis, ensure reliable long-term performance in harsh industrial settings. As highlighted in our resource on alumina ceramic performance characteristics, these material advantages translate directly to industrial insulation applications.

2. Defining High Purity 99% Alumina Ceramic Industrial Insulation Components

High purity 99% alumina ceramic insulation column blocks and washers are precision-engineered components designed for electrical and thermal isolation in industrial systems. These technical ceramics consist of aluminum oxide (Al₂O₃) with minimal additive content (≤1%), ensuring optimal material properties. The insulation column blocks function as structural supports and thermal barriers in high-temperature equipment, while insulator washers provide electrical isolation at mounting points and connections.

These components are characterized by their exceptional dimensional stability with thermal expansion coefficients of 8×10⁻⁶/K, maintaining precise tolerances across temperature fluctuations. Unlike standard 85-95% alumina grades, 99% purity variants offer enhanced mechanical strength (over 400 MPa compressive strength) and superior surface finish (Ra ≤ 0.2μm) critical for high-voltage applications. Their crystalline structure provides consistent performance in semiconductor processing, power generation, and furnace construction where lower-purity ceramics would degrade. For fundamental material properties, refer to our explanation of what alumina ceramic is and its core characteristics.

3. Manufacturing Process of High-Purity Alumina Ceramic Insulators

The production of high-purity alumina ceramic components follows a precision-controlled sequence. It begins with raw material refinement where Bayer-process alumina powder is purified to 99+% Al₂O₃ content through chemical treatment and calcination. The powder undergoes advanced milling to achieve submicron particle sizes (<0.5μm) ensuring microstructural homogeneity. Binders and lubricants constitute less than 1% of the formulation to maintain purity.

Shaping employs either dry pressing for simple geometries or isostatic pressing for complex shapes, applying pressures up to 200 MPa. Components then undergo precision machining in the green state to achieve tolerances within ±0.1%. The critical sintering phase occurs in high-temperature kilns (1600-1800°C) using precisely controlled heating/cooling profiles to achieve >99% theoretical density. Final diamond grinding achieves surface finishes below 0.4μm Ra and dimensional accuracies to ±0.01mm. Rigorous quality verification includes dielectric testing, metallographic analysis, and X-ray inspection to ensure defect-free crystalline structure suitable for industrial insulation applications.

4. Industrial Applications of Al₂O₃ Insulation Column Blocks and Washers

High-purity alumina ceramic insulation components serve critical functions across multiple industrial sectors. In energy generation systems, they provide electrical isolation in turbine monitoring sensors and support structures within high-temperature reactors. The semiconductor industry utilizes these components as wafer processing insulators in CVD and etching equipment where plasma resistance is essential.

Industrial furnace applications employ alumina blocks as thermocouple protection tubes and structural insulation in environments exceeding 1500°C. For power electronics, these washers deliver critical electrical isolation in IGBT modules and busbar systems. Additional applications include: laser system optics mounting, mass spectrometer components, aerospace sensor insulation, and high-frequency RF systems. Their ultra-high vacuum compatibility makes them indispensable in particle accelerator components. As noted in our safety analysis of alumina ceramic maintenance, the same chemical stability that ensures food safety translates to corrosion resistance in industrial chemical processing equipment.

5. Selection Criteria for Industrial-Grade Alumina Ceramic Insulators

Selecting optimal alumina ceramic insulation components requires evaluating multiple technical parameters. First, verify material certification confirming ≥99% Al₂O₃ content with impurity analysis. Assess dielectric properties based on operational voltage, ensuring dielectric strength exceeds application requirements by at least 30%. For thermal applications, confirm the maximum service temperature rating and thermal shock resistance through manufacturer test data.

Critical dimensional considerations include flatness tolerance (<0.01mm/mm for precision mounting), surface finish requirements (typically <0.4μm Ra for electrical applications), and hole/shaft tolerances for mechanical assemblies. Evaluate manufacturer quality certifications (ISO 9001, AS9100) and request material test reports for density (≥3.90 g/cm³), flexural strength (>380 MPa), and volume resistivity (>10¹⁴ Ω·cm). For corrosive environments, review chemical resistance data against specific agents. Finally, consider customization capabilities for specialized geometries or metallization requirements. The versatility highlighted in alumina ceramic applications demonstrates the material’s adaptability to specialized industrial requirements.

6. Technical FAQs: High Purity Alumina Ceramic Industrial Insulators

6.1 How does purity level affect alumina ceramic performance?

Purity directly correlates with key performance metrics. While 95% alumina offers good mechanical properties, 99% grade provides approximately 30% higher thermal conductivity, 40% greater flexural strength, and significantly improved dielectric properties. The reduced glass phase in high-purity alumina minimizes high-temperature creep and enhances chemical resistance.

6.2 What temperature limits apply to these components?

High-purity alumina ceramic insulators maintain structural integrity to 1650°C in oxidizing atmospheres. Maximum continuous service temperatures typically range between 1500-1600°C depending on mechanical load conditions. Thermal shock resistance is excellent with rapid temperature change capabilities exceeding 200°C/second when properly engineered.

6.3 How do alumina insulators compare to polymer alternatives?

Alumina ceramics offer superior performance in high-temperature (>300°C), high-voltage (>10kV), and mechanically demanding applications. They exhibit negligible outgassing in vacuum systems, superior radiation resistance, and permanent dimensional stability where polymers would creep or degrade. Initial costs are higher but lifecycle costs are typically lower in industrial environments.

6.4 What mounting precautions are required?

Use compliant interfaces to accommodate differential thermal expansion with metals. Avoid point loading on edges and apply even torque distribution during assembly. For high-vibration applications, consider resilient mounting systems to prevent impact damage to ceramic components.

Tags: alumina ceramic insulator, Al₂O₃ insulation block, ceramic insulating washer, high purity alumina column, industrial ceramic insulator, alumina spacer block, electrical ceramic isolator, high-temperature ceramic spacer

(High Purity 99% Alumina Ceramic Insulation Column Block Al2o3 Insulator Washer for Industrial)

Supplier

Alumina Technology Co., Ltd focus on the research and development, production and sales of aluminum oxide powder, aluminum oxide products, aluminum oxide crucible, etc., serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services.