Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

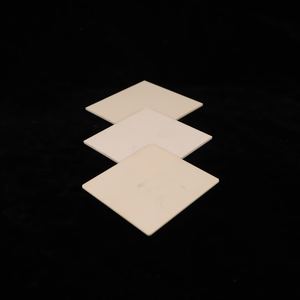

Overview of 315t Alumina Ceramic Textile Tile Plate for Armored Body Armor Vest Hydraulic Press With Mould Pe Body armour Plate Machinr

315t Alumina Ceramic Textile Tile Plate for Armored Body Armor Vest Hydraulic Press With Mould Pe Body armour Plate Machinr is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of 315t Alumina Ceramic Textile Tile Plate for Armored Body Armor Vest Hydraulic Press With Mould Pe Body armour Plate Machinr

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(315t Alumina Ceramic Textile Tile Plate for Armored Body Armor Vest Hydraulic Press With Mould Pe Body armour Plate Machinr)

Specification of 315t Alumina Ceramic Textile Tile Plate for Armored Body Armor Vest Hydraulic Press With Mould Pe Body armour Plate Machinr

These alumina ceramic plates are for body armor. They are tough and lightweight. The plates are made from high-purity alumina. This material is very hard. It stops bullets effectively. Each plate is shaped like a textile tile. This shape fits well in vests. The plates are made using a hydraulic press. The press uses a special mold. It applies 315 tons of pressure. This high pressure makes the ceramic very dense. Dense ceramic is stronger. The press forms the plates precisely. It makes plates to exact sizes. Common sizes are 300mm by 250mm. The thickness is usually 10mm. This thickness provides good protection. The mold ensures consistent shape. Every plate comes out the same. Quality is controlled. The process bonds the ceramic to a PE backing. PE is polyethylene plastic. This plastic backing absorbs impact. It spreads the force from a hit. The combination stops threats. It offers solid protection. The finished plates are ready for vests. Soldiers and police use this armor. It saves lives. The machine makes reliable plates.

(315t Alumina Ceramic Textile Tile Plate for Armored Body Armor Vest Hydraulic Press With Mould Pe Body armour Plate Machinr)

Applications of 315t Alumina Ceramic Textile Tile Plate for Armored Body Armor Vest Hydraulic Press With Mould Pe Body armour Plate Machinr

This alumina ceramic textile tile plate is a key material for modern body armor vests. It offers strong protection against bullets and fragments. The ceramic is very hard and tough. It shatters incoming threats on impact. This ceramic plate is also lightweight. It does not add too much weight to the vest. Soldiers and police officers can move more easily. They feel less tired wearing it all day. The plate is made from alumina ceramic. This material is known for its excellent strength. It is also very resistant to heat and wear.

Manufacturing this ceramic plate needs a special hydraulic press. We use a powerful 315-ton press for this job. The big press provides the necessary force. It shapes the ceramic material under high pressure. The press works with a strong mould. The mould gives the ceramic its exact tile shape and size. This process ensures every plate is consistent. Quality is critical for body armor. The hydraulic press applies steady pressure. It compacts the alumina ceramic material tightly. This makes the finished plate very dense and strong. The dense structure is vital for stopping bullets.

The finished alumina ceramic textile tile plates are then fitted into vests. They fit inside special pockets in the carrier. The ceramic face stops the bullet. The textile backing helps absorb energy. This combination provides reliable protection. It protects lives in dangerous situations. Armor vests using these plates meet high safety standards. They are trusted by military and law enforcement worldwide. The 315-ton press and mould system is essential. It produces these life-saving ceramic plates efficiently.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 315t Alumina Ceramic Textile Tile Plate for Armored Body Armor Vest Hydraulic Press With Mould Pe Body armour Plate Machinr

What is the 315t alumina ceramic textile tile plate for?

This plate is for hydraulic presses. It presses body armor plates. The machine uses a mold. The plate holds the alumina ceramic textile. The plate is strong. It handles the high pressure.

Why choose alumina ceramic for this?

Alumina ceramic is very hard. It resists wear well. It lasts longer than other materials. The pressure is high. Alumina ceramic does not break easily. It keeps the textile safe. The product quality stays good.

Why is 315 tons of pressure needed?

Body armor plates need strong bonding. The textile layers must fuse together. High pressure makes the bond solid. 315 tons gives enough force. It creates a reliable armor plate. Less pressure might not work.

Can I use any mold with this plate?

No. You need the correct mold. The mold must fit the hydraulic press. It must fit the plate size too. Check the mold specifications first. Using the wrong mold is unsafe. It could damage the machine.

How do I handle the ceramic tile plate?

Handle the plate carefully. It is strong but can crack if dropped. Follow the safety instructions. Wear protective gloves. Always place it flat. Store it in a safe place. Keep it away from heavy impacts.

(315t Alumina Ceramic Textile Tile Plate for Armored Body Armor Vest Hydraulic Press With Mould Pe Body armour Plate Machinr)

REQUEST A QUOTE

RELATED PRODUCTS

Alumina Vacuum Chuck Porous Ceramic Plate

RONGXIN High Quality Alumina Ceramic Plate Ceramic Filter Plate for Ceramic Vacuum Filter

High Purity and Density Alumina Ceramic Plate

Best Hardness 92 95 99 Alumina Ceramic Lining Tiles Brick Plate

Micro Porous Ceramic Filter Plate /Alumina Ceramic Disc Plate for Filter