Professional Premium Aluminum Oxide Products Supplier

1. Introduction

When you hear ‘alumina ceramic,’ your mind might jump to high-tech lab equipment or industrial furnace linings—but it’s also quietly revolutionizing home kitchens. Alumina ceramic baking dishes combine exceptional heat resistance with elegant design, making them a favorite among serious home cooks and professional chefs alike. Unlike standard stoneware or porcelain, alumina-enhanced ceramics offer superior durability and thermal shock resistance, ideal for everything from roasting to serving.

In this deep dive, we’ll unpack what makes an alumina ceramic baking dish stand out, compare its various kitchen-ready forms (like the alumina ceramic casserole with lid or alumina ceramic butter dish with lid), and clarify why it shouldn’t be confused with industrial-grade alumina products such as alumina ceramic tubes or grinding discs.

2. What Makes Alumina Ceramic Unique for Baking?

Alumina, or aluminum oxide (Al₂O₃), is a key ingredient in many advanced ceramics. In kitchenware, it’s typically blended into clay bodies or glazes to boost strength and thermal stability. While pure 99% alumina ceramics are too hard and expensive for dinnerware, ‘alumina ceramic’ kitchen items usually contain a moderate percentage—enough to enhance performance without compromising workability.

The result? An alumina ceramic oven dish that won’t crack under rapid temperature changes, retains heat evenly, and resists staining or scratching. This makes alumina ceramic dishes for oven use far more reliable than traditional earthenware, especially for recipes requiring high-heat baking or broiling.

3. Comparing Common Alumina Ceramic Kitchenware Types

Not all alumina ceramic items serve the same purpose. Understanding their differences helps you choose the right piece for your culinary needs.

3.1 Baking and Casserole Dishes

The alumina ceramic casserole dish—often sold with a matching lid—is engineered for slow cooking, baking, and even stovetop-to-oven transitions. Brands like Staub sometimes incorporate alumina-rich ceramics into their lines, leading to search terms like ‘alumina baking dish staub.’ These dishes distribute heat uniformly, preventing hot spots that can burn delicate sauces or custards.

Similarly, alumina ceramic ramekins are perfect for crème brûlée or individual soufflés, thanks to their ability to withstand direct flame or broiler exposure without warping.

3.2 Dinnerware and Serving Pieces

Beyond baking, alumina enhances everyday tableware. Alumina ceramic dinner plates—available in classic white, bold black, or festive designs like alumina christmas ceramic platter—offer chip resistance and a smooth, non-porous surface that’s easy to clean.

You’ll also find specialized items like the alumina ceramic sugar dish, alumina salad ceramic bowl, and alumina ceramic serving platter. These aren’t just pretty; they’re functional. The non-reactive nature of alumina means acidic foods like tomatoes or citrus won’t discolor or degrade the glaze over time.

3.3 Specialty and Decorative Items

Creative uses abound: alumina ceramic plates for painting allow artists to customize dinnerware, while alumina ceramic childrens plates benefit from extra durability. Seasonal collections, such as alumina christmas plates ceramic, blend holiday charm with practical resilience.

Even small accessories like the alumina butter ceramic dish with lid maintain freshness while resisting odors—a subtle but valuable perk.

4. Alumina Ceramic vs. Industrial Alumina Components: Don’t Confuse Them!

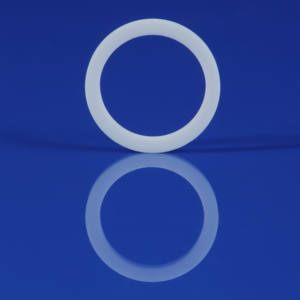

A quick note of clarification: many online searches mix kitchenware with industrial parts. Terms like ‘alumina ceramic tube,’ ‘alumina grinding disc,’ or ‘alumina crucible’ refer to technical ceramics used in labs, manufacturing, or high-temperature processes—not your casserole dish.

For example, an alumina thermocouple protection tube must endure 1600°C+, while your alumina oven ceramic dish is rated for typical kitchen temps (up to ~500°F). Similarly, alumina ceramic disc taps or alumina silicon carbide grinding discs are plumbing or machining components, not bakeware.

While both categories use aluminum oxide, their composition, density, and manufacturing methods differ drastically. Kitchen alumina ceramics prioritize food safety and aesthetics; industrial versions prioritize hardness, purity, and extreme thermal stability.

5. Practical Considerations When Buying

When shopping for alumina ceramic dishes for oven use, look for these features:

- Clear labeling indicating oven, microwave, and dishwasher safety

- Glazes certified lead- and cadmium-free

- Even thickness to prevent warping

- Lids that fit snugly (for casseroles or butter dishes)

Avoid assuming ‘alumina’ means unbreakable—it still requires careful handling. But compared to standard ceramic, it’s significantly tougher.

6. Conclusion

From the versatile alumina ceramic casserole to the sleek alumina black ceramic plates, alumina-enhanced ceramics bring professional-grade performance to home kitchens. Their blend of beauty, durability, and thermal efficiency makes them a smart investment for anyone who bakes, serves, or simply enjoys well-crafted tableware. Just remember: your alumina ceramic baking dish belongs in the oven—not the machine shop.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Alumina. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.