Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

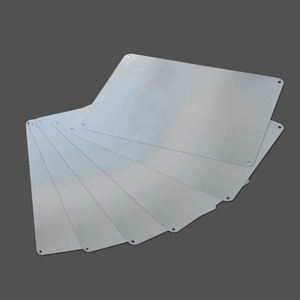

Overview of 95 99Alumina OEM/ODM Ceramic Thin Plate Sheet Ceramic Substrate Plate

95 99Alumina OEM/ODM Ceramic Thin Plate Sheet Ceramic Substrate Plate is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of 95 99Alumina OEM/ODM Ceramic Thin Plate Sheet Ceramic Substrate Plate

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(95 99Alumina OEM/ODM Ceramic Thin Plate Sheet Ceramic Substrate Plate)

Specification of 95 99Alumina OEM/ODM Ceramic Thin Plate Sheet Ceramic Substrate Plate

This is a slim ceramic plate made mainly from alumina. Alumina means light weight aluminum oxide. These plates come in two primary purity levels. One is 95% pure alumina. The various other is 99% pure alumina. The greater pureness offers better performance. Both types are really difficult and strong. They resist put on effectively. They handle high temperatures easily. You can use them where it gets really hot. They don’t thaw or damage down. These plates are also good electrical insulators. Electrical energy does not pass through them conveniently. This is essential for electronic devices. They perform warm well though. Heat steps via them effectively. This assists maintain things great.

These plates are slim and flat. They look like sheets. Individuals call them ceramic substrates. A substratum is a base product. Other components get built on top of it. They are very secure. They don’t change dimension much with warmth. This maintains points precise. They are likewise extremely smooth. The surface area coating is great. This benefits making circuits. The product is chemically inert. Many acids and bases don’t harm it. It doesn’t rust or corrode. This makes it last a long time.

These alumina plates are made use of in numerous sectors. Electronics is a huge customer. They are bases for circuit boards. LED lights commonly utilize them. Power components require them too. Sensing units can be built on them. They are discovered in many tools. We can make them for you. We provide OEM and ODM solutions. OEM means original tools supplier. ODM means original style producer. Tell us what you need. We make the plates to your specifications. We manage the size. We regulate the thickness. We manage the shape. We can make them really thin. We can make them thicker if required. We can cut them into special shapes. We can pierce holes in them. We can add special coverings. We can brighten them added smooth. We can make them rougher. The surface structure is flexible. We fulfill your precise requirements.

(95 99Alumina OEM/ODM Ceramic Thin Plate Sheet Ceramic Substrate Plate)

Applications of 95 99Alumina OEM/ODM Ceramic Thin Plate Sheet Ceramic Substrate Plate

95% to 99% Alumina ceramic slim plate sheets are important substratums. They carry out well in tough problems. These plates withstand high heat properly. They preserve strength also at heats. This makes them ideal for requiring thermal atmospheres. They are outstanding electric insulators. This building is important for lots of electronic usages. They are additionally chemically inert. They withstand attack from several acids and bases. This makes certain lasting security. Their hardness provides great wear resistance. They offer reputable mechanical support.

In electronics, these plates are common. They create the base for thick film circuits. They hold resistors, capacitors, and conductors. They are made use of in crossbreed microelectronics. They support semiconductor devices safely. They work as substrates for various sensors. Temperature level sensors utilize them. Pressure sensors use them. Their stability is essential for accuracy. They are located in power modules. They handle high voltages safely. They separate components effectively. LED packaging depends on them. They handle warmth well. They provide a secure mounting surface area.

Industrial applications prevail. They function as wear-resistant plates. They line tools based on abrasion. They secure machinery components properly. They are made use of in high-temperature heater components. They hold up against thermal cycling accurately. They serve as insulating washers and spacers. They separate warmth in settings up. They are discovered in laser tools. They hold laser elements firmly. They manage warmth dissipation successfully. They create part of thermal monitoring systems.

The medical area uses these ceramics. They are biocompatible. This permits use in certain implants. They are utilized in diagnostic devices. They supply secure systems. Their inertness is vital here. They are made use of in lab instruments. They resist chemical corrosion accurately.

Aerospace and power sectors utilize them too. They fulfill needs for dependability. They do in harsh operating environments. They are integral to numerous modern technologies.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 95 99Alumina OEM/ODM Ceramic Thin Plate Sheet Ceramic Substrate Plate

What is 95-99% Alumina ceramic plate?

This is a thin sheet made mostly from aluminum oxide. The high alumina content gives it excellent properties. It works well for electronic parts. It handles heat and electricity reliably.

How thick can you make these plates?

We can make them very thin. Common thicknesses range from 0.1mm up to 3.0mm. We control thickness precisely. This precision suits demanding applications.

Can you customize the shape and size?

Yes. We offer OEM and ODM services. We cut the ceramic to your exact specifications. We make special shapes. We also drill holes if needed. Tell us your requirements.

Is this ceramic good for high temperatures?

Yes. Alumina ceramic handles high heat very well. It withstands temperatures over 1600°C. It does not easily break down under thermal stress. This makes it ideal for heaters and sensors.

Where are these ceramic plates commonly used?

They are used in many electronic devices. You find them in circuit boards for insulation. They are used in LED lighting. They work well in power modules. They also serve in sensors and heaters needing thermal stability.

(95 99Alumina OEM/ODM Ceramic Thin Plate Sheet Ceramic Substrate Plate)

REQUEST A QUOTE

RELATED PRODUCTS

High Temperature Wear Resistance Alumina Ceramic Substrate Customized Ceramic Orifice Plate Parts with Cutting Bending Services

038mm05mm06mm08mm Al2o3 Alumina Ceramic Substrates Plate Sheet 995

Dry Pressure Moulding Cnc Machining Alumina Ceramic groove Slot Round Disc Plate Dish

High-Temperature 1650C Silicon Carbide Ceramic Plates Alumina/MgO/SiO2 Moulded Tiles Kiln Shelf Powder Plate Welding Brick MgO

95% Al2O3 Alumina Ceramic Insulator Ceramic Plate for Insulation Application