Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

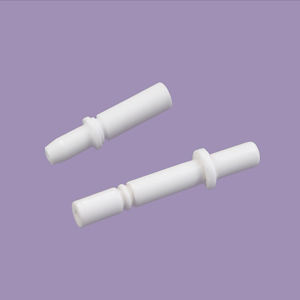

Overview of 95% Alumina Ceramic Ignition Needle Pin Al2o3 Spark Electrode for Burner Electrode

95% Alumina Ceramic Ignition Needle Pin Al2o3 Spark Electrode for Burner Electrode is precision-engineered components made from high-purity aluminum oxide (Al₂O₃), offering superior mechanical strength, thermal stability, and electrical insulation. These pins are widely used in electronics, semiconductor equipment, medical devices, and industrial machinery where extreme durability and precision are required. With excellent wear and corrosion resistance, they ensure long-lasting performance in demanding environments.

Features of 95% Alumina Ceramic Ignition Needle Pin Al2o3 Spark Electrode for Burner Electrode

Extreme Hardness & Wear Resistance – Ideal for high-friction applications

High-Temperature Stability – Withstands up to 1600°C without degradation

Excellent Electrical Insulation – Perfect for electronic and semiconductor uses

Chemical & Corrosion Resistance – Resists acids, alkalis, and harsh chemicals

Precision Machining – Tight tolerances for critical applications

(95% Alumina Ceramic Ignition Needle Pin Al2o3 Spark Electrode for Burner Electrode)

Specifications of 95% Alumina Ceramic Ignition Needle Pin Al2o3 Spark Electrode for Burner Electrode

This 95% alumina ceramic ignition needle pin acts as a spark electrode in burners. It develops the stimulate needed to spark gas or gas. The material is aluminum oxide, referred to as Al2O3. This ceramic offers exceptional hardness and longevity. It endures severe temperatures approximately 1500 ° C. High thermal shock resistance protects against fracturing during rapid heating or air conditioning. The pin deals with intense electrical voltages without breaking down. Its electrical insulation residential or commercial properties are outstanding. This avoids undesirable existing leak.

The alumina make-up ensures strong mechanical stamina. It stands up to wear and abrasion efficiently. The pin preserves performance in harsh, harsh environments. It does not corrosion or deteriorate from chemicals. Moisture and dust exposure reason no problems. The ceramic surface remains smooth over time. This consistency warranties trustworthy spark generation. Ignition failings end up being unusual.

Requirement measurements differ to fit various heater models. Usual diameters range from 2mm to 6mm. Sizes generally expand from 50mm to 200mm. Personalized dimensions are offered for details applications. The idea layout concentrates on precise stimulate targeting. This maximizes ignition performance.

Setup is uncomplicated. The pin incorporates conveniently into existing ignition systems. Marginal upkeep is needed. Its durability decreases substitute regularity. Operational costs stay low.

This element fits gas cooktops, industrial heating systems, and heating boilers. It operates in commercial cooking area tools and lab burners. Performance remains stable under continual procedure. The alumina ceramic makes certain security and dependability.

(95% Alumina Ceramic Ignition Needle Pin Al2o3 Spark Electrode for Burner Electrode)

Applications of 95% Alumina Ceramic Ignition Needle Pin Al2o3 Spark Electrode for Burner Electrode

This alumina ceramic ignition pin takes care of sparking tasks in burners dependably. It’s made from 95% pure Al2O3 ceramic. This material is really difficult. It endures extreme heat well. The pin stimulates continually to light gas fuel. You locate it inside central heating boilers, ovens, heating systems, and commercial heating systems. It works with gas hot water heater and home heater. Industrial kitchen equipment utilizes it as well. Industrial drying lines count on it.

The ceramic building offers essential benefits. It deals with high temperatures near flames quickly. It doesn’t melt or warp like metal can. The material is a strong electrical insulator. Triggers jump only where required. This stops misfires or weak triggers. Moisture or chemicals do not harm the ceramic. Corrosion isn’t a problem. The surface stays smooth. Triggers dive accurately whenever.

This pin lasts a very long time. It doesn’t put on down quickly. It withstands erosion from constant triggering. Upkeep requires decline significantly. You change it much less frequently. Burner systems run with less disruptions. Downtime lowers. The pin supplies steady ignition over years. Devices dependability boosts. Running prices go down.

It fits common ignition systems flawlessly. Installment is typically easy. Professionals know this part well. Its efficiency is verified in hard setups. Factories use it daily. Power plants depend on it. It takes care of requiring cycles without failing. The spark keeps solid and trustworthy.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 95% Alumina Ceramic Ignition Needle Pin Al2o3 Spark Electrode for Burner Electrode

What is the main material of this ignition needle? It uses 95% alumina ceramic. Alumina ceramic is Al2O3. This material is very strong. It handles high heat well. It lasts a long time. It works perfectly as a spark electrode.

Why choose alumina ceramic for an ignition electrode? Alumina ceramic resists extreme temperatures. It does not corrode. It sparks reliably. It insulates electricity. Metal electrodes wear out faster. Ceramic lasts longer.

What applications is this ignition needle suitable for? It fits gas burners. It works in industrial heaters. It works in home boilers. It works in kitchen stoves. It ignites gas-air mixtures safely. It is common in heating systems.

How do I install the ignition needle? Turn off the burner first. Remove the old electrode. Insert the new ceramic needle. Secure it firmly. Check the gap distance. The gap is between the tip and burner head. Follow your appliance manual for the gap size. Wrong gaps cause poor ignition.

What are the benefits over metal electrodes? Ceramic does not rust. It does not melt. It handles higher temperatures. You replace it less often. This saves money. Metal electrodes corrode and fail faster. Ceramic is more reliable.

(95% Alumina Ceramic Ignition Needle Pin Al2o3 Spark Electrode for Burner Electrode)

REQUEST A QUOTE

RELATED PRODUCTS

Super hard high temperature chemical resistant alumina ceramic pins

Customized 95% Glazed Alumina Ceramic Electrode Igniter With Pin

Custom High Insulating Glazed 95% Alumina Ceramic Igniter Durable Spark Plug Ignition Pin Needle for Heater Industrial Furnace

95% Alumina Ceramic Ignition Needle Pin Al2o3 Spark Electrode Igniter

Shenxing Ceramic Insulator 95% Alumina Ceramic Spark Plugs Ignition Ceramic Pin Electrode