Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

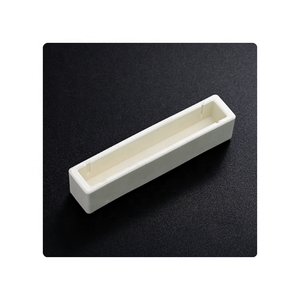

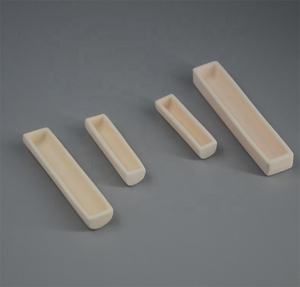

Overview of Alumina Box Ceramic Boat Sagger

Alumina Box Ceramic Boat Sagger is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of Alumina Box Ceramic Boat Sagger

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(Alumina Box Ceramic Boat Sagger)

Specifications of Alumina Box Ceramic Boat Sagger

Our Alumina Box Ceramic Watercraft Sagger is developed challenging. It utilizes high-purity alumina ceramic. This material handles extreme temperature levels. It withstands chemical strikes well. The surface stays smooth. This protects against contamination. The box shape holds parts firmly. It supplies excellent stability throughout processes.

The boat style permits very easy stacking. Several systems fit together neatly. This makes the most of heating system room. It improves set processing efficiency. Uniform warmth circulation is vital. The design guarantees consistent results. Gas flow moves openly around parts. This is very important for responses.

Standard dimensions are offered. Common interior dimensions consist of 100x100x50mm. Bigger dimensions like 200x200x100mm exist. Wall surface thickness is generally 5-8mm. This balances stamina and weight. Custom-made dimensions are feasible. We match your details demands.

Operating temperatures are high. Continual use up to 1650 ° C is common. Brief bursts can reach 1750 ° C. Thermal shock resistance is solid. Unexpected temperature adjustments create less cracking. This implies the sagger lasts longer.

Chemical resistance is outstanding. Acids, antacid, and molten salts do not damage it easily. This fits rough furnace environments. Steel vapors will not stick to it. The surface area remains clean. Purity remains high set after batch.

Mechanical toughness is trusted. It supports hefty loads without flexing. The framework remains stiff under heat. This stops bending or sagging. Parts remain exactly positioned.

This sagger is used in lots of markets. Semiconductor wafer processing requires it. Powder metallurgy counts on it. Ceramic sintering uses it. Warmth therapy heaters need it. Lab testing devices take advantage of it. Kiln furniture applications find it vital. It’s a core device for high-temperature job.

(Alumina Box Ceramic Boat Sagger)

Applications of Alumina Box Ceramic Boat Sagger

Alumina ceramic boats are crucial tools in lots of high-temperature industrial processes. These tough containers hold materials firmly during firing. They excel in semiconductor production. Workers place silicon wafers inside them for procedures like diffusion and annealing. The boats hold up against extreme heat inside heaters. They also withstand chemical reactions well. This protects against unwanted contamination of delicate wafers. Product pureness is crucial in electronic devices. Alumina boats assist keep that pureness.

Laboratories utilize these watercrafts extensively also. Researchers rely upon them for sintering powders. They are ideal for calcination actions. Example analysis usually needs secure, inert holders. Alumina supplies that security. Managing examples safely between handling phases is simpler with these boats. Their smooth surface areas reduce material sticking. Cleansing them is straightforward after usage. This saves time and effort.

The product itself supplies crucial advantages. Alumina ceramic manages abrupt temperature modifications well. It doesn’t break easily under thermal tension. This durability means watercrafts last longer. They use great worth with time. High purity alumina reduces the risk of introducing impurities. It responds inadequately with the majority of chemicals. This inertness is important for constant outcomes. The boats keep their shape and strength also after duplicated high-temperature cycles. They offer dependable performance set after batch.

Alumina boats offer well in heat therapy of metals. They bring little parts via solidifying or brazing heating systems. Powder metallurgy refines depend on them for forming parts. Glaze firing in porcelains utilizes alumina boats to hold products. They shield kiln racks from drips. Their non-reactive nature guarantees fired glazes stay pure. These boats are basic workhorses where warm and purity matter most.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Alumina Box Ceramic Boat Sagger

Here are 5 FAQs for Alumina Box Ceramic Boat Sagger:

What is this ceramic boat used for?

This Alumina Box Ceramic Boat Sagger carries silicon wafers or other small parts inside high-temperature furnaces. It protects items during processes like diffusion, annealing, or CVD. The boat holds items securely. It prevents contamination.

Why is alumina the material?

Alumina handles extreme heat very well. It resists chemical attack. Alumina keeps its shape at high temperatures. It heats and cools without cracking easily. This reliability is essential. Other ceramics might fail faster.

What temperatures can it handle?

These alumina boats work reliably up to about 1600°C (2912°F). Some special grades go higher. Check the specific grade for exact limits. Never exceed the maximum temperature rating. Overheating damages the boat.

How do I clean it?

Cleaning is usually simple. Use mild acids or bases dissolved in water. Avoid harsh mechanical scrubbing. Ultrasonic cleaners work well for stubborn dirt. Rinse thoroughly with pure water. Dry completely before reuse. Proper cleaning prevents contamination.

Can I get a custom size?

Yes. Many suppliers offer custom sizes and shapes. Provide your exact dimensions. Specify the required alumina purity grade. Ask about lead times for custom orders. Standard sizes are often available faster. Choose what fits your furnace and parts best.

(Alumina Box Ceramic Boat Sagger)

REQUEST A QUOTE

RELATED PRODUCTS

XTL Sintyron High Temperature Ceramic Alumina Boat Ceramic Combustion Boat

High Purity High Temperature square 99 Alumina Ceramic Boat for Thermal Analysis

XTL Sintyron Cnc Machining Al2o3 Square Alumina Ceramic Combustion Crucible Tray Boat For Furnace

Factory Custom 99% High Purity Al2O3 Alumina Combustion Boat Alumina Ceramic Part Rectangle Alumina Ceramic Boats Crucible

SINTYRON High Temperature Resistant High Purity square Al2o3 Alumina Ceramic Evaporating Combustion Boat Crucible for Lab Use