Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

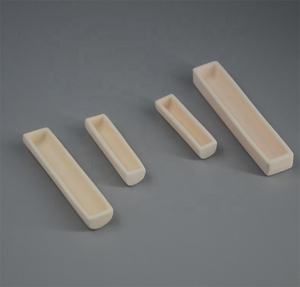

Overview of High Temperature Ceramic Alumina Boat/Ceramic Combustion Boat

High Temperature Ceramic Alumina Boat/Ceramic Combustion Boat is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of High Temperature Ceramic Alumina Boat/Ceramic Combustion Boat

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(High Temperature Ceramic Alumina Boat/Ceramic Combustion Boat)

Specifications of High Temperature Ceramic Alumina Boat/Ceramic Combustion Boat

Below’s the product content concerning Heat Porcelain Alumina Boats:

These ceramic combustion watercrafts take care of extreme warm dependably. They are made from high purity alumina material, 99.5% or better. This purity guarantees excellent chemical resistance. The watercrafts stand up to attack from a lot of acids and alkalis. They additionally stand up to rough molten salts and hostile gases. This makes them secure for requiring laboratory and industrial procedures.

Alumina boats supply impressive thermal stability. They operate continually at temperature levels up to 1750 ° C. Short-term exposure to 1800 ° C is possible. The product endures thermal biking well. It stands up to thermal shock effectively. This resilience stops splitting during fast temperature changes.

The boats have an extremely smooth surface finish. This decreases example sticking. It makes cleaning simpler between usages. Their reduced porosity is one more crucial feature. Porosity degrees are usually listed below 5%. This thick structure stops contamination. It quits gases or liquids from leaking into the ceramic body. Test pureness stays high.

These boats are available in numerous standard sizes. Common sizes range from 50mm to 200mm. Widths differ from 10mm to 50mm. Heights are usually 10mm to 25mm. Custom-made sizes are additionally offered. They fit standard tube heaters perfectly. The boats are dimensionally steady under heat. They keep their shape exactly.

Use these alumina boats for sample calcination. They help sintering procedures. They are suitable for stimulant screening. They serve well in products research. They take care of annealing procedures. They are vital for TGA evaluation. They carry out reliably in powder handling.

(High Temperature Ceramic Alumina Boat/Ceramic Combustion Boat)

Applications of High Temperature Ceramic Alumina Boat/Ceramic Combustion Boat

High temperature ceramic alumina boats handle extreme warm. They are necessary tools in laboratories and industry. These little ceramic trays work reliably in heaters. They bring examples safely with intense thermal procedures.

Laboratories utilize alumina boats as crucibles. They hold examples throughout heating examinations. Materials evaluation depends on them. They won’t contaminate examples. They will not split from sudden warm adjustments. This makes results trustworthy.

The semiconductor industry relies upon these watercrafts. They transport silicon wafers and electronic parts. They go into high-temperature diffusion heaters. They are stable. They don’t launch impurities. Tidy room processes require this integrity.

Metal screening utilizes ceramic watercrafts as well. They contain metal powders or items for heat treatment. They stand up to the heats needed for sintering or annealing. They maintain sample honesty.

Catalysis research typically utilizes these ceramic boats. They hold driver products during reaction studies. Their inert nature is essential. They don’t interfere with the chemical processes. Scientists obtain accurate data.

Powder handling needs durable containers. Alumina boats bring powders with calcination or shooting actions. They withstand duplicated home heating and cooling cycles. This conserves cash over time. They last a lot longer than more affordable options.

These watercrafts are solid. They resist chemical strike. They hold up in extreme heat. Their flat shape offers great sample exposure. They are simple but crucial devices for high-temperature job.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Temperature Ceramic Alumina Boat/Ceramic Combustion Boat

What is a High Temperature Ceramic Alumina Boat? It’s a container made from alumina ceramic. It handles extreme heat. People use it in labs and industries. It holds samples during heating processes. The material is very pure. It resists thermal shock. It doesn’t react with most chemicals. This makes it reliable.

What are the typical applications of Ceramic Alumina Boats? These boats are common in sample preparation. They work in furnaces and kilns. They are used for ashing, calcination, and sintering. Labs use them for analyzing materials. Industries use them in quality control. They are also found in research and development. They carry small parts or powders during heating.

What temperature range can these ceramic boats withstand? These boats handle extreme heat. They can go up to 1700°C. Some types go even higher. The exact limit depends on the alumina grade. They maintain strength at high temperatures. They don’t melt or deform easily. This makes them suitable for long heating cycles.

How should I handle and maintain Ceramic Alumina Boats? Handle these boats with care. They are brittle. Avoid dropping them. Clean them after each use. Use mild detergents or heat. Do not subject them to sudden temperature changes. Let them cool down slowly. Store them in a dry place. Check for cracks before use. Replace damaged boats immediately.

Are there different sizes available? Yes, these boats come in various sizes. You can choose based on your sample size. Common sizes range from small boats for tiny samples to larger ones. Custom sizes are also possible. Check the specifications before ordering. The size affects the heating efficiency. Pick the right size for your application.

(High Temperature Ceramic Alumina Boat/Ceramic Combustion Boat)

REQUEST A QUOTE

RELATED PRODUCTS

99.7% alumina ceramic tga boat al2o3 fire clay high temperature crucible

High Purity High Temperature square 99 Alumina Ceramic Boat for Thermal Analysis

SINTYRON High Temperature Resistant High Purity square Al2o3 Alumina Ceramic Evaporating Combustion Boat Crucible for Lab Use

Labs Al2o3 Alumina Ceramic Combustion Boat

High Purity Alumina Ceramic Square Boat Box Sagger and Crucible with Lid Refractory Product