Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

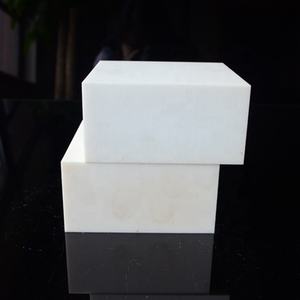

Overview of High Purity 99% Alumina Ceramic Blocks Protective Ceramic Tiles Al2O3 Structural Parts

High Purity 99% Alumina Ceramic Blocks Protective Ceramic Tiles Al2O3 Structural Parts is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of High Purity 99% Alumina Ceramic Blocks Protective Ceramic Tiles Al2O3 Structural Parts

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(High Purity 99% Alumina Ceramic Blocks Protective Ceramic Tiles Al2O3 Structural Parts)

Specification of High Purity 99% Alumina Ceramic Blocks Protective Ceramic Tiles Al2O3 Structural Parts

These high purity 99% alumina ceramic blocks are tough engineering materials. They are also known as protective tiles or Al2O3 structural parts. This material offers outstanding performance in demanding settings. It is incredibly hard. This hardness rivals many metals. It resists wear exceptionally well. This makes it perfect for parts that face constant abrasion.

It handles extreme heat. This ceramic maintains strength at temperatures over 1500°C. It doesn’t melt easily. This heat resistance is crucial for furnace linings or thermal processing parts. The material is also a strong electrical insulator. It works reliably in high-voltage applications.

Chemical stability is another major benefit. The high purity alumina resists attack from many acids and alkalis. It doesn’t corrode like metals. This property is vital for chemical processing equipment or corrosive environments. The ceramic blocks are dimensionally stable too. They won’t warp or shrink significantly under heat stress.

These blocks are commonly used as wear-resistant liners. They protect chutes, hoppers, and pipelines carrying abrasive materials. They serve as armor tiles in ballistic protection systems. The blocks are essential structural components in semiconductor manufacturing tools. They are found in furnace furniture like setters and kiln shelves. They work well as electrical insulators in high-temperature sensors.

The specification is clear. The material is 99% minimum aluminum oxide (Al2O3). Density is high, typically 3.85 g/cm³ or more. This dense structure boosts strength and wear resistance. Flexural strength is very good. It often exceeds 300 MPa. The material provides excellent dielectric strength. Hardness is extremely high, measured on the Mohs scale. Surface finish can be tailored. It ranges from standard as-fired to precision ground. Dimensions are customizable. We produce blocks to your exact size requirements. Color is typically white or ivory.

(High Purity 99% Alumina Ceramic Blocks Protective Ceramic Tiles Al2O3 Structural Parts)

Applications of High Purity 99% Alumina Ceramic Blocks Protective Ceramic Tiles Al2O3 Structural Parts

High purity alumina ceramic blocks are nearly pure Al2O3. This makes them very hard and strong. They resist wear exceptionally well. These properties are vital for demanding industrial uses. They handle extreme heat easily. They also resist chemical attack effectively. These blocks are ideal for severe environments.

Manufacturers use them as protective tiles. These tiles line equipment constantly exposed to abrasion. Think mining chutes, hoppers, and conveyor systems. They shield the underlying metal structure. This drastically cuts down on wear and tear. It extends equipment life significantly. Downtime for repairs is reduced. Operational costs fall.

These ceramic blocks are also key structural parts. Engineers choose them where strength matters under pressure. They perform reliably in high-temperature settings. Furnace linings and kiln furniture benefit greatly. Thermal processing equipment uses them extensively. They maintain integrity where metals might fail. They provide stability.

The electrical insulation properties are excellent. Alumina blocks are perfect insulators in demanding electrical applications. They safely isolate components carrying high voltage. Semiconductor manufacturing relies on their purity. They prevent contamination. Electronic components stay protected.

Chemical plants need materials that withstand harsh substances. Alumina ceramic blocks resist most acids and alkalis. Reactor linings and pump components use them. They prevent leaks and corrosion damage. Processing equipment stays safer longer. Production runs smoother.

The high density and smooth surface are advantages. Moving parts experience less friction. This reduces energy consumption. It also lowers maintenance needs. Machinery operates more efficiently. Wear parts last much longer. Replacement costs decrease.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Purity 99% Alumina Ceramic Blocks Protective Ceramic Tiles Al2O3 Structural Parts

What exactly are these alumina ceramic blocks?

These are super dense industrial tiles made from 99% pure aluminum oxide powder. We fire them at super high temperatures. This makes them incredibly hard and resistant to wear. They are structural parts designed for tough environments needing protection.

Where would someone typically use these blocks?

You see them in heavy industry protecting equipment. They line chutes, hoppers, and pipes handling abrasive materials like ore or sand. Factories use them inside machinery parts that face constant friction. They also act as heat shields or electrical insulators.

Why choose alumina ceramic over steel or other materials?

Alumina beats steel for wear resistance in gritty conditions. It lasts much longer before wearing out. It handles extreme heat far better than most metals. It resists chemical corrosion well. It also insulates electricity effectively. This saves money on frequent replacements.

Can you make custom shapes besides standard tiles?

Yes. We specialize in custom fabrication. We machine the fired ceramic blocks into complex parts. We make tubes, rods, plates, liners, and unique components. Tell us your exact dimensions and application. We produce parts to fit your specific machinery needs.

How do you install these ceramic tiles effectively?

Proper bonding is critical. Clean the metal surface thoroughly first. Use a high-strength epoxy adhesive designed for ceramics and metal. Apply the adhesive evenly. Press the tile firmly onto the substrate. Follow the adhesive manufacturer’s cure time exactly. This ensures a strong, lasting bond.

(High Purity 99% Alumina Ceramic Blocks Protective Ceramic Tiles Al2O3 Structural Parts)

REQUEST A QUOTE

RELATED PRODUCTS

High Purity Al2o3 Ceramic Block Square Alumina Ceramic Plate Brick

Insulator Alumina Irregular Block 99 Milk White Al2O3 Ceramic Electronic Structural Part

Customizable High Quality Alumina Ceramic Part Al2o3 Industrial Ceramic Unique Shape Block

High Temperature 99% 99.5% Al2o3 Alumina Ceramic Block Blank Brick

High Purity 99% Alumina Ceramic Insulation Column Block Al2o3 Insulator Washer for Industrial