Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

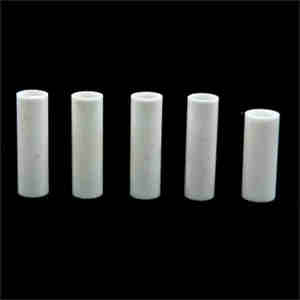

Overview of High Compressive Strength Alumina Industrial Ceramic Shaft Parts Ceramic Plunger Piston for Liquid Filling

High Compressive Strength Alumina Industrial Ceramic Shaft Parts Ceramic Plunger Piston for Liquid Filling is engineered from 99%+ pure aluminum oxide (Al₂O₃), delivering unmatched durability and precision for demanding industrial applications. Designed to operate in extreme conditions, these plungers excel in high-wear, high-temperature, and corrosive environments, making them perfect for pumps, valves, fuel injection systems, and chemical processing equipment.

Features of High Compressive Strength Alumina Industrial Ceramic Shaft Parts Ceramic Plunger Piston for Liquid Filling

Superior Wear Resistance – Outlasts metal plungers in abrasive environments.

High-Temperature Stability – Maintains integrity up to 1600°C.

Corrosion & Chemical Resistance – Immune to acids, alkalis, and solvents.

Extreme Hardness (Hv 1500+) – Minimizes friction and extends service life.

Precision Machined – Tight tolerances for smooth, leak-free operation.

Customizable Designs – Available in various diameters, lengths, and surface finishes.

(High Compressive Strength Alumina Industrial Ceramic Shaft Parts Ceramic Plunger Piston for Liquid Filling)

Specifications of High Compressive Strength Alumina Industrial Ceramic Shaft Parts Ceramic Plunger Piston for Liquid Filling

Our alumina ceramic shaft components and plunger pistons deliver extraordinary efficiency in demanding fluid filling procedures. These components withstand severe pressures consistently. They use premium solidity and put on resistance compared to metal alternatives. This directly expands service life and decreases expensive downtime for maintenance.

The material structure is 99% high-purity alumina. This ensures outstanding chemical inertness. Extreme chemicals and destructive fluids will not degrade the ceramic surface. You obtain reliable procedure even with aggressive solvents or acidic/alkaline services. Consistent dimensional stability is an additional vital benefit. The parts preserve their exact shape under high loads and temperature variations usual in filling up lines.

Surface coating is critical. Our plungers and shafts feature an ultra-smooth Ra 0.4 μm surface finish. This minimizes friction and protects against liquid leakage past the seal. It likewise considerably lowers wear on mating seal products. You attain reputable sealing efficiency cycle after cycle.

Dimensional precision is firmly controlled. Regular resistances for diameters are held within ± 0.01 mm. Size tolerances are normally ± 0.02 mm. This precision guarantees ideal fitment within your existing pump and shutoff assemblies. Concentricity is preserved to high criteria for smooth, vibration-free operation. These components are crafted for straight substitute in numerous commercial filling up machines. They manage pressures going beyond 300 MPa compressive stamina. Usual applications consist of high-pressure metering pumps, precision application systems, inkjet printing heads, and pharmaceutical filling tools. They stand out with fluids like adhesives, lubricants, gas, inks, cosmetics, and foodstuff.

(High Compressive Strength Alumina Industrial Ceramic Shaft Parts Ceramic Plunger Piston for Liquid Filling)

Applications of High Compressive Strength Alumina Industrial Ceramic Shaft Parts Ceramic Plunger Piston for Liquid Filling

Alumina ceramic shaft parts and bettor pistons supply big advantages in fluid filling up devices. These parts handle tough jobs dependably. Alumina ceramic is extremely difficult. This solidity fights use better than steel. It maintains its form completely under heavy tons. This implies constant loading volumes over a long period of time. Transforming parts less often saves money and downtime.

Chemical resistance is another major benefit. Alumina ceramic make fun of corrosive liquids, acids, and solvents. Steel parts rust or corrode promptly in these problems. Ceramic plungers stay smooth and intact. This stops leaks and product contamination. Tidiness is essential in loading food, drinks, and chemicals. Ceramic parts do not react with the fluids. They do not include unwanted tastes or particles.

Low rubbing is crucial for bettor pistons. The ultra-smooth ceramic surface glides quickly inside the cyndrical tube. This reduces the pressure required to move the plunger. It cuts power use. It likewise reduces warmth accumulation from rubbing. Less rubbing implies much less wear on the bettor itself and the cylinder liner. This expands the life of the whole pump assembly.

These ceramics handle high stress well. They will not deform or crack under the pressures in quickly, specific filling up operations. Dimensional stability is essential. It makes certain every fill is exactly the exact same volume. This precision prevents product giveaway and waste. Dependability enhances total devices efficiency. Devices run much longer without stopping for component adjustments. Maintenance costs drop dramatically. Utilizing high-strength alumina ceramics makes liquid filling lines much more effective and trustworthy.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Compressive Strength Alumina Industrial Ceramic Shaft Parts Ceramic Plunger Piston for Liquid Filling

What are the main benefits of alumina ceramic shaft parts and plunger pistons? These parts are extremely hard. They resist wear very well. This reduces maintenance costs. They have low friction. This ensures smooth liquid filling. They handle high pressure without damage.

How does high compressive strength help in liquid filling applications? Compressive strength prevents cracking under pressure. Pumps operate reliably. Dosing accuracy improves. Product waste decreases. Downtime reduces.

Are these ceramic parts resistant to chemical corrosion? Yes. Alumina ceramic ignores most chemicals. Acids and solvents don’t affect it. Parts stay intact. Liquid purity remains high. Contamination risks drop.

Can these parts withstand high temperatures? Absolutely. They endure over 1500°C. Heat doesn’t weaken them. Performance stays stable. Metal parts often fail here. Ceramic avoids that problem.

How long do alumina ceramic plungers last versus metal ones? They outlast metal significantly. Wear is minimal even with abrasive liquids. Replacement happens less often. Lifecycle costs go down. Efficiency improves long-term.

(High Compressive Strength Alumina Industrial Ceramic Shaft Parts Ceramic Plunger Piston for Liquid Filling)

REQUEST A QUOTE

RELATED PRODUCTS

High Strength Various Specifications 3Y-TZP Zirconia Ceramic Plunger Alumina Ceramic Stopper

High Polished Outer Diameter Wearable 99% Alumina Ceramic Plunger bar Rod

High Quality High Pressure Washer Alumina Ceramic Plunger Piston

Customized High Precision Alumina Ceramic Valve Plunger

High Precision 95 99 Ceramic Piston Pump Alumina Ceramic Piston Plunger Bushing Custom Processing Pressure Washer CNC Machining