Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

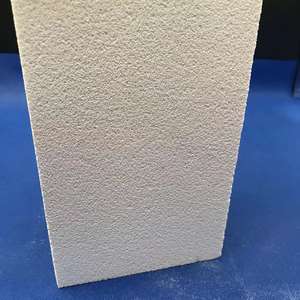

Overview of Industrial Ceramic Al2O3 High Temperature Wear Resistant Block High Hardness Alumina Precision Ceramic

Industrial Ceramic Al2O3 High Temperature Wear Resistant Block High Hardness Alumina Precision Ceramic is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of Industrial Ceramic Al2O3 High Temperature Wear Resistant Block High Hardness Alumina Precision Ceramic

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(Industrial Ceramic Al2O3 High Temperature Wear Resistant Block High Hardness Alumina Precision Ceramic)

Specification of Industrial Ceramic Al2O3 High Temperature Wear Resistant Block High Hardness Alumina Precision Ceramic

Industrial ceramic Al2O3 blocks withstand extreme warmth and put on exceptionally well. They are made from light weight aluminum oxide. This product is exceptionally difficult. It manages temperatures far beyond what metals can endure. These blocks will not thaw or warp easily in extreme warm. They keep their shape and strength accurately.

Their surface solidity is really high. This hardness shields them versus constant abrasion and rubbing. Parts made from this alumina ceramic last much longer than metal parts. This decreases downtime and maintenance expenses. You see these blocks used in difficult spots. They function well as wear plates, liners, and guides. They secure equipment in harsh settings.

Accuracy manufacturing makes certain regular measurements. Resistances are tight. These blocks fit exactly where required sought after equipment. Their thermal stability stops fracturing under rapid temperature level changes. This is important for processes involving heating and cooling down cycles. Electric insulation is one more essential property. These blocks safely separate parts in high-voltage setups.

Chemical resistance is superb. Acids, antacid, and solvents don’t damage them easily. This makes them appropriate for corrosive handling locations. They withstand aggressive chemicals without breaking down. Their toughness holds up under heavy loads. This alumina ceramic is a popular selection for requiring industrial jobs. Usual uses include kiln furniture, cutting devices, pump parts, and seal faces. Customized shapes and sizes are possible.

(Industrial Ceramic Al2O3 High Temperature Wear Resistant Block High Hardness Alumina Precision Ceramic)

Applications of Industrial Ceramic Al2O3 High Temperature Wear Resistant Block High Hardness Alumina Precision Ceramic

Industrial ceramic Al2O3 obstructs address challenging problems. These blocks are made from alumina ceramic. Alumina ceramic is exceptionally tough. It resists scratches and wear effectively. This makes it best for components that scrub together regularly. Equipments last much longer making use of these blocks. They change steel components that break also fast.

These ceramic blocks handle severe warmth conveniently. They work fine in furnaces and kilns. Temperature levels over 1600 ° C are no problem. They do not thaw or deteriorate like metals do. This is essential for high-temperature handling devices. Think steel manufacturing or glass manufacturing. Heat shields and heater nozzles utilize them.

The firmness of Al2O3 ceramic is one more huge benefit. It’s much tougher than solidified steel. This makes it superb for cutting devices and grinding media. It grinds products successfully. It remains sharp a lot longer. This conserves money on substitutes. Accuracy is additionally crucial. Suppliers form these blocks to extremely tight resistances. They fit completely right into complicated machinery. They supply secure, trustworthy efficiency. This is crucial for sensors, seals, and insulators.

Chemical resistance matters as well. Alumina ceramic will not corrosion. It handles strong acids and alkalis well. It operates in rough chemical environments. This is important for pumps and shutoffs. It avoids contamination in sensitive processes. Electric insulation is an additional advantage. These blocks don’t carry out electrical energy. They separate electric components safely. They are utilized in spark plugs and electronic substratums.

These blocks are difficult in several methods. They incorporate solidity, heat resistance, and chemical stability. This one-of-a-kind mix uses services steel parts can not match. Industries count on them for demanding applications. They minimize downtime. They lower maintenance prices. They enhance process dependability.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Industrial Ceramic Al2O3 High Temperature Wear Resistant Block High Hardness Alumina Precision Ceramic

Industrial Ceramic Al2O3 High Temperature Wear Resistant Block High Hardness Alumina Precision Ceramic – FAQs

What is this ceramic block made from?

It’s made from alumina ceramic. Alumina is aluminum oxide, called Al2O3. This material gives the block its special properties. It is very hard. It resists wear extremely well. It handles very high heat.

How hot can this ceramic block get?

This alumina block works reliably at very high temperatures. Its maximum continuous use temperature is around 1600°C (2912°F). It handles short bursts even hotter. Many metals fail at much lower temperatures. This makes it ideal for hot places.

Where is this wear resistant block used?

You see it in tough industrial jobs. It lines equipment handling abrasive materials, like in mining or powder processing. It acts as wear plates in machinery. It serves as liners in pumps handling slurries. It works in high heat areas like furnace parts. It protects surfaces from constant rubbing and scraping.

Why pick alumina ceramic over metal?

Alumina ceramic beats metal in key ways. It is much harder than most steels. This means it resists scratching and gouging far better. It doesn’t rust or corrode like metal can. It handles much higher temperatures before softening. It lasts much longer in abrasive, high heat conditions. This reduces downtime and replacement costs.

Can this block be machined or shaped?

Yes, but it requires special methods. You can machine alumina ceramic precisely. Diamond tools are needed. The ceramic is very hard. Standard metal cutting tools won’t work. Grinding or specialized diamond machining is the way. Suppliers often provide blocks in standard sizes. They can custom machine them to your exact needs before delivery. Handle finished pieces carefully. They are brittle and can chip if struck hard.

(Industrial Ceramic Al2O3 High Temperature Wear Resistant Block High Hardness Alumina Precision Ceramic)

REQUEST A QUOTE

RELATED PRODUCTS

95% Alumina Block Heat Resistance Al2O3 Ceramic Grinding Plate

Heat Resistance Alumina Ceramic Sintering Plate Al2O3 Ceramic Block

Industry Abrasive 99% Al2o3 Alumina Ceramic Insulator Block Brick Tile

High Purity 99% Alumina Ceramic Blocks Protective Ceramic Tiles Al2O3 Structural Parts

Good Temperature Wear Resistance Al2o3 Alumina Ceramic Block