Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

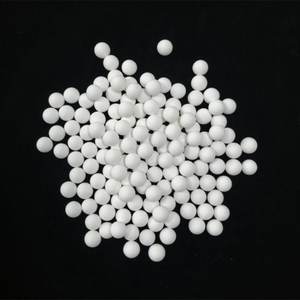

Overview of Factory Activated Hollow Alumina Sphere Bubble Balls 0.5-1mm Gamma Alumina Ball

Alumina balls are high-purity ceramic grinding media known for their exceptional hardness, wear resistance, and thermal stability. Ideal for industrial applications like milling, catalysis, and wear-resistant components.

Features of Factory Activated Hollow Alumina Sphere Bubble Balls 0.5-1mm Gamma Alumina Ball

High mechanical strength & durability

Excellent chemical & thermal stability

Superior wear & corrosion resistance

Available in various sizes & purity grades

Low contamination for precision processes

(Factory Activated Hollow Alumina Sphere Bubble Balls 0.5-1mm Gamma Alumina Ball)

Specification of Factory Activated Hollow Alumina Sphere Bubble Balls 0.5-1mm Gamma Alumina Ball

These hollow alumina sphere bubble rounds determine 0.5 to 1 millimeter in diameter. They are little ceramic balls. Their unique hollow structure develops a bubble-like shape. This style is essential. The material is gamma-phase alumina. Gamma alumina is a really energetic type of light weight aluminum oxide. It is not the usual alpha stage. The factory carries out an activation action. This activation prepares the spheres for prompt use. You get them prepared to function right out of the bundle.

The gamma alumina stage offers a significant area. The hollow framework adds even more revealed surface area. More area implies more locations for chain reactions or adsorption to occur. This enhances performance dramatically. The rounds are exceptionally strong. They withstand squashing forces well. They deal with high warmth fantastically. Chemical attack seldom harms them. This durability makes sure long life in demanding problems. They work dependably over many cycles.

The mix of high area, hollow framework, and gamma stage activation makes these balls very effective. They are perfect driver providers. They support active components properly. They stand out at adsorbing gases or fluids. Their shapes and size allow easy flow with systems. Packing beds remain uniform. Pressure goes down stay low. This boosts overall procedure performance.

Make use of these turned on hollow alumina rounds in refining catalysts. They work well in petrochemical procedures. They are perfect for gas drying systems. They serve in specialized filtering setups. They fit many demanding industrial processes needing high-performance ceramic media. Their unique residential or commercial properties solve particular design difficulties.

(Factory Activated Hollow Alumina Sphere Bubble Balls 0.5-1mm Gamma Alumina Ball)

Applications of Factory Activated Hollow Alumina Sphere Bubble Balls 0.5-1mm Gamma Alumina Ball

These hollow alumina ball bubble balls gauge 0.5 to 1.0 millimeters. They are made from gamma-phase alumina. The manufacturing facility activation procedure makes them ready for instant use. This conserves significant preparation time for consumers. The hollow structure supplies distinct benefits.

Their main application is as catalyst sustains. The large surface of gamma alumina is optimal for this. The hollow spheres supply reduced thickness. This reduces general stimulant bed weight substantially. It additionally improves liquid circulation dynamics inside reactors. The balls keep high toughness regardless of being hollow. They stand up to crushing under stress. Their thermal security is excellent. They stand up to heats usual in catalytic procedures. This makes them trustworthy for demanding refinery operations. They are also made use of in chemical synthesis plants.

These balls work well as adsorbents. The permeable gamma alumina structure successfully catches particles. They remove contaminations from gases or fluids efficiently. Their tiny dimension makes certain great call with the fluid stream.

The hollow rounds act as useful fillers. They add useful residential properties to composite materials. They reduce weight significantly. They improve thermal insulation. They enhance mechanical toughness. Their round form helps disperse anxiety uniformly.

They are utilized in specialized finishes and refractories. The balls enhance thermal resistance. They reduced the product’s density. They boost toughness under extreme conditions. The factory activation makes sure constant performance promptly. This integrity is critical for industrial processes requiring precision.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Factory Activated Hollow Alumina Sphere Bubble Balls 0.5-1mm Gamma Alumina Ball

Here are five common questions about our factory activated hollow alumina sphere bubble balls, 0.5-1mm, gamma alumina ball:

What exactly are these hollow alumina sphere bubble balls?

These are tiny, hollow balls made from gamma alumina. They are very light because they are empty inside. We make them specifically for chemical processes needing a special catalyst support material. Their shape and material are key.

Why make them hollow?

Hollow means they weigh much less than solid balls. This low weight is important. It lets gases flow around them easily inside reactors or towers. Better gas flow often means the chemical reactions work better. It also means you can use a bigger volume of catalyst without making the whole system too heavy.

What is the 0.5-1mm size good for?

This small size is a common choice. It fits well in many reactor designs, especially fluidized bed reactors. The balls move and mix well in these systems. The size gives a large surface area relative to their volume. This large surface is crucial for effective catalysis.

What does “factory activated” mean? Why is it important?

“Factory activated” means the balls are fully ready to use right out of the bag. We do the necessary high-temperature calcination step here at our facility. This step turns the raw material into the active gamma alumina phase. It also makes the structure stable. You save time and avoid the hassle and cost of doing this activation step yourself.

Are there any special handling or safety steps?

Handle them carefully. Avoid rough handling that could crush the hollow spheres. Wear gloves and eye protection. Don’t breathe in the dust. While gamma alumina itself is generally stable, the activation process gives off heat. We handle that safely at the factory so you don’t have to worry about it.

(Factory Activated Hollow Alumina Sphere Bubble Balls 0.5-1mm Gamma Alumina Ball)

REQUEST A QUOTE

RELATED PRODUCTS

17-19% Al2O3 Composition Inert Alumina Ceramic Ball Support Media 3mm 6mm 10mm 25mm for Petroleum Industry

50ml 100ml 150ml 200ml 300ml 500ml 1000ml 1200ml Wear Resistance Alumina Ceramic Horizontal Ball Milling Jars For Ball Mills

Spherical Activ Alumina Ball Best Activ Alumina

92% Alumina Ceramic Grinding Balls for Industrial Use

High Alumina 99 Al2O3 Ceramic Balls Alumina Ceramic Beads 1-80mm