Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

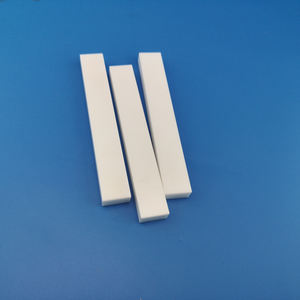

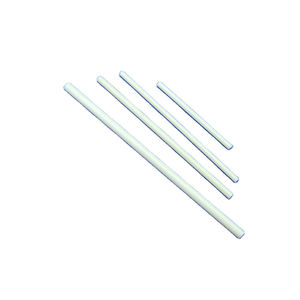

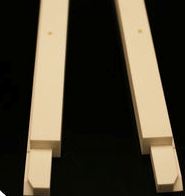

Overview of High Purity White Ceramic Alumina Rod/Tube/Bar Wear Resistant Custom Industrial Ceramic Parts

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of High Purity White Ceramic Alumina Rod/Tube/Bar Wear Resistant Custom Industrial Ceramic Parts

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of High Purity White Ceramic Alumina Rod/Tube/Bar Wear Resistant Custom Industrial Ceramic Parts

This alumina ceramic product is high pureness light weight aluminum oxide. It uses impressive efficiency popular commercial setups. This ceramic is extremely hard. It stands up to wear incredibly well. Components made from it last a lot longer than metal alternatives. This lowers downtime and substitute prices.

The product endures severe warmth. It handles temperature levels much past what steels tolerate. Thermal shock resistance is solid. Fast temperature changes create minimal damages. Chemical stability is another vital advantage. Acids, alkalis, and solvents do not quickly strike it. This makes it suitable for corrosive environments.

Electric insulation buildings are exceptional. This is important for several electric and electronic applications. The surface coating achievable is exceptionally smooth. This decreases friction and avoids material sticking. Personalization is simple. We create rods, tubes, bars, and complex shapes to accurate requirements. Measurements, lengths, and resistances match your exact demands.

Normal pureness degrees exceed 95%, often getting to 99.5% or more. High purity directly improves solidity, put on resistance, and thermal residential or commercial properties. These components are essential in mining devices, pump parts, and valve seats. They carry out well in heating system fixtures, semiconductor handling tools, and lab device. They are used in wear plates, cutting tools, and overviews. Their resilience improves performance across numerous sectors.

Applications of High Purity White Ceramic Alumina Rod/Tube/Bar Wear Resistant Custom Industrial Ceramic Parts

High purity white ceramic alumina provides exceptional toughness for demanding industrial settings. This advanced material stands up to serious rubbing and wear far better than steels or plastics. Customized poles, tubes, and bars made from it resolve tough issues across many areas.

Semiconductor manufacturers rely on these ceramic parts. They handle delicate silicon wafers and components inside chip handling devices. The product causes zero contamination. It stays smooth under continuous use. This shields costly electronic devices. Manufacturing remains clean and reputable.

Mining and mineral processing equipment experiences hefty abrasion. Ceramic alumina liners, poles, and put on plates shield machinery. They withstand consistent grinding from rocks and slurries. This reduces downtime dramatically. Upkeep prices decrease. Tools lasts much longer.

Chemical plants need components standing up to rough acids and solvents. White ceramic alumina tubes and poles manage destructive liquids without damages. They function well in pumps, valves, and circulation meters. Efficiency remains constant. Chemical attack does not compromise them.

Heat furnaces require materials that won’t fail under warmth. These ceramic poles and tubes maintain strength over 1500 ° C. They give architectural support or guide components in severe heat. They do not warp or melt. Thermal security is exceptional.

Other demanding uses exist. Oil and gas boring tools utilize ceramic wear sleeves. Fabric overviews need smooth, long lasting surfaces. Clinical device elements call for absolute pureness. Food handling gain from non-contaminating parts. Laser systems use exact ceramic tubes. Customized forms are available. Manufacturers can get parts created for certain wear factors. This extends the life of crucial equipment.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Purity White Ceramic Alumina Rod/Tube/Bar Wear Resistant Custom Industrial Ceramic Parts

High Purity White Ceramic Alumina Rods/Tubes/Bars: Your Top 5 Questions Answered

What makes white ceramic alumina special?

This material is extremely hard. It resists scratching exceptionally well. Its high purity means fewer impurities. This leads to better performance in tough conditions. It handles chemicals without corroding. High temperatures won’t damage it easily.

Can I get specific sizes and shapes?

Yes. We produce rods, tubes, and bars in custom dimensions. Tell us your needed outer diameter, inner diameter (for tubes), and length. We can machine these parts to your exact drawings. Precision is guaranteed.

How well do they resist wear?

Alumina ceramic rods and tubes resist wear extremely effectively. They last much longer than steel or plastic in abrasive settings. This reduces how often parts need replacing. Downtime decreases. Your machinery runs longer.

Are there limits to customization?

Some limits exist. Very thin walls or extremely complex shapes might be difficult. Very large single-piece parts could be challenging. We assess every request individually. We find the best solution for your specific needs.

How should I handle these parts?

Handle them carefully. They are hard but can be brittle if impacted sharply. Avoid dropping them onto hard surfaces. Wear gloves to prevent skin oils contaminating the surface. Store them securely to prevent chipping or rolling.

REQUEST A QUOTE

RELATED PRODUCTS

Alumina Ceramic Friction Disc For Barmag Texturing Machinery Key Component Pu Disk Disc

New Products Bar Specification Customize Hight Purity Vacuum Bag Packing Indium Rod

1050 6061 Aluminum Hexagonal bar / 7075 Aluminum Hexagonal Rod

3003 Extruded Aluminium Bar Good Molding Performance High Corrosion Resistance Custom Aluminum Square Bar Aluminium Welding Rod

Professional Aluminum bar Factory 1000-7000 Series Heavy Duty Aluminum Rod