Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

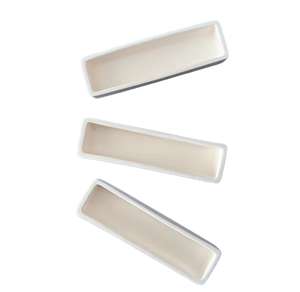

Overview of 95% 99% Alumina Sagger Crucible Square Ceramic Boat with Cover

95% 99% Alumina Sagger Crucible Square Ceramic Boat with Cover is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of 95% 99% Alumina Sagger Crucible Square Ceramic Boat with Cover

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(95% 99% Alumina Sagger Crucible Square Ceramic Boat with Cover)

Specifications of 95% 99% Alumina Sagger Crucible Square Ceramic Boat with Cover

This alumina sagger crucible is a square ceramic watercraft. It consists of a matching cover. We offer two material grades: 95% alumina and 99% alumina. The greater purity 99% alumina supplies much better efficiency. It holds up against greater temperatures. It stands up to chemical attack much better. It lasts longer under difficult problems. The 95% alumina gives an economical selection. It functions well for several conventional procedures.

These crucibles manage high warmth incredibly well. They are secure up to 1650 ° C (3000 ° F). Their thermal shock resistance is great. This suggests they manage quick temperature level modifications. Unexpected home heating or cooling down reasons less cracking danger. This integrity is important for commercial furnaces.

The material is really dense. This decreases porosity. Much less porosity quits products from saturating right into the crucible walls. Your examples remain pure. Contamination threats drop substantially. The surface finish is smooth. This makes cleansing much easier after use. Particles doesn’t stick as much.

These square watercrafts been available in standard sizes. Typical dimensions consist of 50x50mm, 100x100mm, and larger. Custom-made measurements are feasible. We make them to fit your heater or process demands. The style consists of a well-fitting cover. The cover safeguards components from heating system atmospheres. It reduces worldly loss throughout shooting.

These alumina saggers are essential laboratory and commercial devices. They are best for sintering ceramic components. They benefit calcining powders. They handle firing electronic elements like MLCCs. They are used in powder metallurgy. They offer in driver study. Their stamina and purity make them flexible.

(95% 99% Alumina Sagger Crucible Square Ceramic Boat with Cover)

Applications of 95% 99% Alumina Sagger Crucible Square Ceramic Boat with Cover

These alumina sagger crucibles are difficult ceramic boats developed for demanding high-temperature tasks. They manage intense heat remarkably well. The high alumina material, 95% or 99%, provides excellent thermal stability. They resist unexpected temperature changes without splitting. This makes them perfect for sintering procedures. Sintering bonds powder particles with each other under heat. These crucibles hold the parts securely during firing.

They are additionally essential for annealing and heat therapy. Products need controlled home heating and cooling down to achieve specific buildings. The alumina crucibles stand up to these cycles dependably. Their chemical inertness is a major and also. They do not respond with most products placed inside them. This purity is important for growing crystals. Crystal growth calls for a contaminant-free atmosphere. The crucible provides that steady, tidy room.

Powder handling relies on these watercrafts too. They securely have powders throughout calcination or other thermal therapies. The powder needs defense from heater ambiences. The crucible functions as an obstacle. The tight-fitting cover is critical. It avoids contamination and reduces material loss. It assists keep a consistent atmosphere inside the crucible. This is important for regular results.

The square shape uses useful advantages. It optimizes room inside heater kilns. Extra components or product can be refined in one run. This boosts performance. Their toughness suggests they last much longer than less expensive alternatives. They make it through repeated thermal cycling. This decreases replacement expenses gradually. These alumina crucibles offer critical duties in laboratories and sector. They support innovative product growth and manufacturing.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 95% 99% Alumina Sagger Crucible Square Ceramic Boat with Cover

What exactly are these alumina sagger crucibles used for?

These square ceramic boats hold materials during high-temperature processes. They protect items inside kilns or furnaces. Common uses include firing ceramics, sintering metals, and heat-treating electronic components. The cover keeps contamination out.

Why choose 95% or 99% alumina?

The percentage shows how pure the ceramic material is. Higher purity means better performance. 99% alumina handles much higher temperatures than 95%. It resists chemicals better. It also lasts longer under tough conditions. Both work well, pick based on your specific heat needs and budget.

How hot can these crucibles get?

The maximum safe temperature depends on the alumina grade. Crucibles made from 95% alumina typically handle temperatures up to 1650°C. Crucibles made from 99% alumina withstand even higher heat, often up to 1800°C. Always check the manufacturer’s exact rating for your model.

Are these crucibles strong? Do they break easily?

Alumina ceramic is very hard and resists wear well. It handles thermal shock better than many materials. But it is still brittle like most ceramics. Avoid sudden temperature changes. Don’t drop them or bang them hard. Handle carefully, especially when hot. Proper care makes them last a long time.

How do I take care of these alumina boats?

Let them cool down slowly after use. Avoid quenching them in water. Clean them carefully between uses. Use mild detergents or specialized ceramic cleaners. Avoid harsh chemicals that might attack the surface. Inspect regularly for cracks or chips. Damaged crucibles should be replaced for safety.

(95% 99% Alumina Sagger Crucible Square Ceramic Boat with Cover)

REQUEST A QUOTE

RELATED PRODUCTS

99.7 Al2o3 Alumina Ceramic Crucible Boat

High 99 Al2o3 Zirconia Ceramic Alumina Boat With Lid

Corundum Crucible Ceramic Square Alumina Crucible Boat Cylinder Industrial Ceramic Substrate Plates Customizable Cutting Service

Industrial 99 Alumina Ceramic Spacer For Graphite Boat

Mullite Cordierite Saggar Al2o3 Alumina 99 % Corundum Cylindrical Ysz Zro2 Material Zirconia Ceramic Crucible and Boat