Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

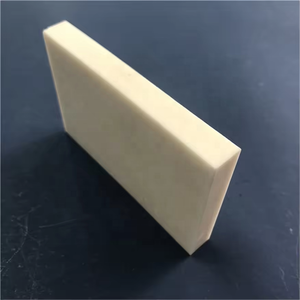

Overview of Customized Al2O3 Ceramic Part 95% Alumina Ceramic Block With Holes

Customized Al2O3 Ceramic Part 95% Alumina Ceramic Block With Holes is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of Customized Al2O3 Ceramic Part 95% Alumina Ceramic Block With Holes

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(Customized Al2O3 Ceramic Part 95% Alumina Ceramic Block With Holes)

Specification of Customized Al2O3 Ceramic Part 95% Alumina Ceramic Block With Holes

This ceramic component uses 95% alumina (Al2O3). It provides excellent toughness and solidity. This product endures really high temperatures quickly. It deals with extreme heat without damage. The ceramic resists wear exceptionally well. It preserves its form under heavy tons. Its surface area stays smooth even after lengthy use. Electric insulation is an additional significant advantage. It securely obstructs high voltages. This makes it ideal for electrical uses. The ceramic additionally stands up to chemical attack. Rough acids and bases don’t harm it. This makes certain long life in tough settings.

We make these components to your precise needs. You define the shapes and size. You inform us the hole pattern required. The holes can be straight or tilted. Opening dimensions are exact according to your drawing. Tolerances are tight for a great fit. We equipment each piece thoroughly. Our process ensures high dimensional precision. Surface area finishes are smooth. This protects against undesirable friction. Customized forms are feasible. We adapt the style for your application. This versatility resolves particular engineering problems.

These blocks function well in numerous sectors. Electronics utilize them for shielding parts. Industrial machinery requires them for wear components. Heating system cellular linings use them because of heat tolerance. Clinical devices count on their biocompatibility. Semiconductor tools use them for precision. Laser systems require their thermal security. They are excellent substrates for sensors. Fluid handling utilizes them for rust resistance. Pump seals benefit from their hardness. They are reliable sought after atmospheres. Regular efficiency is ensured.

(Customized Al2O3 Ceramic Part 95% Alumina Ceramic Block With Holes)

Applications of Customized Al2O3 Ceramic Part 95% Alumina Ceramic Block With Holes

Customized Al2O3 ceramic parts made from 95% alumina ceramic blocks with holes are extremely useful in tough jobs. These parts are really strong and deal with heats well. They stand up to putting on down and last a long period of time. This makes them best for demanding circumstances.

The holes in these ceramic blocks are crucial. They can be formed and positioned exactly where required. This is essential for suitable parts with each other appropriately. You see these blocks utilized a whole lot in electronic devices. They hold parts in place and quit electricity from triggering problems. The openings allow cords pass through safely. They additionally help manage warmth build-up.

Machinery advantages greatly also. These ceramic blocks direct relocating components. They lower rubbing and protect against metal-to-metal call. The holes might be for lubrication or placing screws. In high-temperature furnaces, they work as assistances or spacers. They don’t melt or warp quickly. The holes allow hot air or gases to move around parts.

Chemical processing uses these porcelains. They resist assault from solid acids and bases. The holes can regulate fluid flow or let sensing units job. Semiconductor producing relies on their pureness and stability. Holes assist in wafer handling or gas circulation.

Modification is the large benefit. You get the exact size block you require. The hole pattern matches your equipment completely. You pick the opening size and shape. This addresses details issues in your process. The product itself is a workhorse. It handles electric seclusion, warm, and chemical exposure dependably. It doesn’t conduct electrical power. It stays secure under thermal tension. It stands up to rough chemicals.

These ceramic blocks are a functional option. They enhance efficiency in many industrial setups. Their design flexibility meets one-of-a-kind application demands.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Customized Al2O3 Ceramic Part 95% Alumina Ceramic Block With Holes

Customers often ask these questions about our custom 95% alumina ceramic blocks with holes:

What makes 95% alumina ceramic good for these parts? This material is very hard. It resists wear extremely well. It handles high heat without changing. It doesn’t react with most chemicals. It’s also a good electrical insulator. These features make it reliable for tough jobs.

Can you make the blocks exactly how I need them? Yes. We specialize in custom shapes and sizes. Tell us your requirements. We make the block dimensions to fit your application. We precisely position and size the holes based on your drawings. Our process adapts to your specific needs.

What hole types and sizes can you do? We machine many hole types. This includes straight holes, stepped holes, threaded holes, and blind holes. We handle small diameters accurately. We achieve tight tolerances on hole placement and size. Consistency is critical for assembly or flow. We ensure it.

Why choose these blocks over metal or plastic? Metal corrodes and conducts electricity. Plastic melts or deforms under heat or stress. Our alumina blocks solve these problems. They last longer in abrasive, hot, or corrosive settings. They provide electrical isolation where needed. They offer a stable, durable solution.

How do you guarantee the quality? We use strict controls throughout production. We inspect the raw alumina powder first. We monitor each manufacturing step closely. We measure the final blocks carefully. We check dimensions, hole accuracy, surface finish, and density. We test samples for key properties like strength. This confirms every batch meets the high standard.

(Customized Al2O3 Ceramic Part 95% Alumina Ceramic Block With Holes)

REQUEST A QUOTE

RELATED PRODUCTS

99% Al2O3 0-1mm Bauxite Ore White Fused Alumina for Ceramic Industry Raw Materials From Aluminium & SiO2 Block & Brick Patterns

Custom High Heat Resistant Alumina Ceramics Structural Parts Al2O3 Machining Parts Block Components 99% Alumina Ceramic

Aluminum Oxide Ceramic Board Polished 99.7% Alumina Ceramic Sheet Al2O3 Plate Ceramic Block

Heat Resistance 99% Alumina Ceramic Plate Block Industrial Al2o3 Sheet

Higher Purity 95% Alumina Ceramic Bar Al2o3 Alumina Ceramic Block Thin Plate Alumina Ceramic Substrate