Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

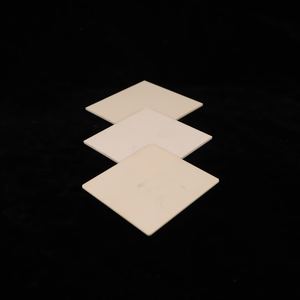

Overview of Insulation 96% Alumina Ceramic Plate/sheet Al2o3 Thin Substrate

Insulation 96% Alumina Ceramic Plate/sheet Al2o3 Thin Substrate is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of Insulation 96% Alumina Ceramic Plate/sheet Al2o3 Thin Substrate

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(Insulation 96% Alumina Ceramic Plate/sheet Al2o3 Thin Substrate)

Specification of Insulation 96% Alumina Ceramic Plate/sheet Al2o3 Thin Substrate

Alumina ceramic plates supply excellent performance. This product includes 96% pure aluminum oxide. That high purity makes it very strong and stable. It deals with severe warm well. You can use it securely up to 1500 degrees Celsius. It cools down gradually without fracturing. This thermal shock resistance is very good.

The material is a solid electric insulator. It blocks electrical power effectively. This makes it perfect for electronic usages. You discover it under circuit card. It holds parts securely. It quits electrical shorts. High voltage situations need this insulation.

This ceramic is very difficult. It withstands wear and scratches. It lasts longer than many steels. Rough settings don’t damage it quickly. Chemical resistance is another advantage. Acids and alkalis won’t hurt it. Harsh chemicals are not an issue.

Home plates are dense and non-porous. Moisture can not penetrate them. This stops deterioration and leakage. They preserve strength in wet problems. Vacuum compatibility is typical. Outgassing is marginal. This matches clinical and vacuum cleaner applications.

You can get these plates in slim sheets. Typical densities range from 0.5 mm to 3mm. Customized dimensions are often offered. Surface area surfaces are smooth. Precision grinding makes certain flatness. Tight tolerances satisfy requiring specifications.

These plates work well for heating system components. They support products during high warm handling. Semiconductor tools utilize them as substratums. Laser systems gain from their security. Burner insulators depend on them. Electric feedthroughs use this ceramic. It secures wires getting in units. Lots of commercial procedures require this reputable material. Its buildings solve difficult engineering issues.

(Insulation 96% Alumina Ceramic Plate/sheet Al2o3 Thin Substrate)

Applications of Insulation 96% Alumina Ceramic Plate/sheet Al2o3 Thin Substrate

These insulation alumina ceramic plates handle severe warm well. They operate in challenging places where regular products stop working. The 96% alumina web content gives excellent electric insulation. This matters for electronics needing no present leaks. Many sectors rely on these slim Al2O3 plates.

In electronics, they serve as durable bases for circuits. They hold delicate wiring and parts securely. Their smooth surface is perfect for publishing circuit courses. The plates manage warmth successfully. This stops parts like power transistors from getting also warm. They are common in LED lights and power modules.

Industrial heating systems and heating systems make use of these plates also. They separate hot components safely. Home plates stand up to continuous high heat without breaking. This makes heating system cellular linings last a lot longer. They are important parts in high-temperature sensing units and thermocouples.

Production uses them for wear resistance. They line courses for unpleasant materials. The plates protect surface areas from getting scraped. Laser reducing benefits from their security. They give a level, heat-resistant base for accurate work. Their hardness helps reducing devices stay sharp longer.

These alumina sheets are chemically steady. Rough chemicals do not harm them quickly. This is vital in chemical handling devices. Labs utilize them as reputable surface areas for experiments requiring warmth. Their stability guarantees consistent outcomes.

The thin account permits fitting into limited rooms. This saves area in complex assemblies. Designers appreciate their flexibility. They offer a practical service for demanding thermal and electrical demands.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Insulation 96% Alumina Ceramic Plate/sheet Al2o3 Thin Substrate

What exactly is this alumina ceramic plate?

This is a thin, flat ceramic sheet made mostly from aluminum oxide. We call it 96% alumina or Al2O3. It’s engineered for demanding technical jobs. Think electrical insulation, high heat areas, or wear protection.

Why pick 96% alumina over other materials?

It offers an excellent balance. It handles very high temperatures well. It’s super strong electrically. It resists chemical corrosion effectively. It also boasts good mechanical strength and hardness. It handles sudden temperature changes better than many ceramics. Plastic or metal often can’t match this performance.

How hot can this plate actually get?

It withstands continuous use up to about 1600°C (2912°F). Its low thermal expansion helps prevent cracking under heat stress. This makes it reliable in furnaces, heaters, and high-power electronics.

Is the surface finish important?

Yes, very important. We provide plates with very smooth surfaces. This precision is crucial. It ensures reliable performance in electronics. It prevents arcing. It provides a stable base for circuits or coatings. Rough finishes can cause problems.

What precautions are needed when using it?

Handle it carefully. While strong under compression, it’s brittle like glass. Avoid impacts or bending forces. Sharp knocks can chip or break it. Use appropriate tools for cutting or drilling. Wear safety gear. Its hardness requires diamond tools for machining.

(Insulation 96% Alumina Ceramic Plate/sheet Al2o3 Thin Substrate)

REQUEST A QUOTE

RELATED PRODUCTS

Huge size Round 80% 95% 99% 99.7% alumina ceramic plate disc substrate

High Impact Resistance Alumina Ceramic Lining Tile Al2o3 Ceramic Hex Plate Hexagonal Alumina Ceramic Sheet

99% Alumina Ceramic Disc Alumina Ceramic Plate

1500 High Temperature Resistance square Plate 96 Alumina Ceramic Sheet

99% Al2o3 Industrial Fine Honeycomb Ceramic Plate Alumina Ceramic Disc