Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

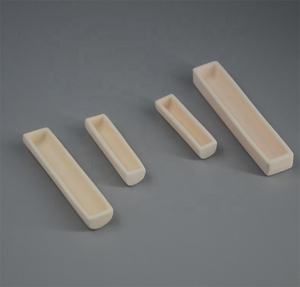

Overview of 95 99 Alumina Corundum Ceramic Combustion Boat Crucible

95 99 Alumina Corundum Ceramic Combustion Boat Crucible is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of 95 99 Alumina Corundum Ceramic Combustion Boat Crucible

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(95 99 Alumina Corundum Ceramic Combustion Boat Crucible)

Specifications of 95 99 Alumina Corundum Ceramic Combustion Boat Crucible

These burning boat crucibles use high-purity alumina ceramic. The alumina content reaches 95% or 99%. This high purity supplies excellent efficiency. The material is corundum ceramic. Corundum is very tough. It provides premium resistance to warm and chemicals. These crucibles hold up against very heats. The maximum use temperature level is around 1700 ° C or 3100 ° F. They take care of thermal shock well. Unexpected temperature changes create less breaking. This is necessary in heater work.

The ceramic has high density. It is thick and strong. This avoids gases and fluids from leaking through. The material is very hard. It resists scrapes and abrasion. This maintains the boat shape steady in time. The surface is smooth. It is very easy to clean. Examples do not stick boldy. The watercrafts are chemically inert. The majority of acids and antacids do not attack them. This stays clear of sample contamination. The boats keep purity.

Criterion sizes are readily available. Usual lengths are 50mm, 70mm, 90mm, 100mm, 120mm. Sizes differ as necessary. The watercraft form is open. It has a shallow trough. This style enables simple sample loading. It additionally promotes excellent gas flow. Completions are typically raised slightly. This avoids spillage. The boats are white or beige. This is the all-natural color of pure alumina. They are inflexible. They do not bend or flex.

These boats are perfect for high-temperature processes. They operate in tube heating systems and stifle furnaces. They are utilized for example burning, ashing, and calcination. Typical applications include coal testing, concrete evaluation, and catalyst researches. They serve well in chemical labs and product research. Handling is simple. Use standard tongs for hot boats.

(95 99 Alumina Corundum Ceramic Combustion Boat Crucible)

Applications of 95 99 Alumina Corundum Ceramic Combustion Boat Crucible

These 95-99% alumina diamond ceramic burning watercrafts are necessary lab devices. They take care of extreme warmth very well. Their major task is holding examples during high-temperature procedures. Laboratories use them regularly for ashing tests. These examinations find out how much ash is in materials like coal or food. The watercrafts function flawlessly inside muffle furnaces. They hold up against temperature levels as much as 1600 ° C or perhaps 1700 ° C quickly. This high warmth tolerance is vital. Examples shed away completely. The ceramic watercraft remains intact.

Chemical evaluation laboratories rely on these crucibles also. They need inert containers. Alumina does not respond with the majority of materials. This guarantees example purity. Contamination won’t occur. The watercrafts are suitable for calcination procedures. Calcination modifications materials making use of heat without melting them. Industries like cement production usage this. The ceramic watercrafts handle the intense heat needed. They additionally function well for sintering small components. Sintering bonds powders making use of heat below their melting point.

Product screening makes use of these boats frequently. Scientists research how materials behave under heat. They observe phase modifications or weight management. The ceramic watercrafts provide a stable, non-reactive platform. They are also crucial in thermogravimetric analysis (TGA). TGA determines weight changes as temperature level modifications. The boat’s stability ensures exact results. Its high pureness doesn’t interfere with measurements. These watercrafts are solid and stand up to thermal shock. Abrupt temperature adjustments hardly ever crack them. This longevity makes them cost-efficient. They last a lot longer than less costly choices. Cleansing them is straightforward after usage. Just clean or wash them out. They await the next sample. Their regular efficiency is relied on worldwide. Labs taking care of demanding warmth procedures pick alumina boats. They deliver reputable results batch after set.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 95 99 Alumina Corundum Ceramic Combustion Boat Crucible

What’s this ceramic boat made of?

It’s built from alumina corundum ceramic. Two grades exist: 95% alumina and 99% alumina. The 99% version offers higher purity. This means better performance under extreme conditions.

How hot can it get?

These boats handle high heat. They withstand temperatures up to 1650°C (3000°F). The 99% alumina type handles slightly higher temperatures than the 95% type. Don’t exceed the rated maximum temperature. Sudden temperature changes can crack them.

Will chemicals damage it?

It resists most acids and alkalis well. Strong acids like hydrofluoric acid or hot concentrated alkalis can attack it. Avoid these aggressive chemicals. Check chemical compatibility before use.

How do I clean it?

Cleaning is straightforward. Use warm water and mild detergent. A soft brush helps remove residues. Avoid harsh abrasive cleaners. They might scratch the surface. Dry it completely before heating it again.

How long will it last?

Lifespan varies. It depends on usage conditions. High temperatures, rapid heating/cooling cycles, and harsh chemicals shorten its life. Gentle handling and proper cleaning extend its use. Inspect it regularly for cracks or wear. Replace it if damaged.

(95 99 Alumina Corundum Ceramic Combustion Boat Crucible)

REQUEST A QUOTE

RELATED PRODUCTS

Factory Custom 99% High Purity Al2O3 Alumina Combustion Boat Alumina Ceramic Part Rectangle Alumina Ceramic Boats Crucible

XTL Sintyron Thermal Analysis Square Alumina Ceramic Crucible Boat

High Purity High Temperature square 99 Alumina Ceramic Boat for Thermal Analysis

Alumina Crucible Boat Combustion Boat Machinable Ceramics

High purity corundum crucible evaporation alumina ceramic boat for furnace