Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

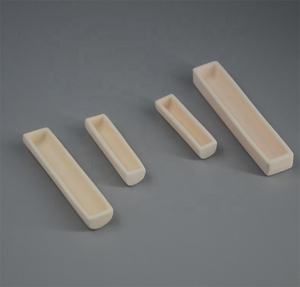

Overview of High Purity Alumina Ceramic Boat Pot High Temperature Fireclay Crucibles for Furnace at a Great Refractory Ceramic Plates

High Purity Alumina Ceramic Boat Pot High Temperature Fireclay Crucibles for Furnace at a Great Refractory Ceramic Plates is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of High Purity Alumina Ceramic Boat Pot High Temperature Fireclay Crucibles for Furnace at a Great Refractory Ceramic Plates

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(High Purity Alumina Ceramic Boat Pot High Temperature Fireclay Crucibles for Furnace at a Great Refractory Ceramic Plates)

Specifications of High Purity Alumina Ceramic Boat Pot High Temperature Fireclay Crucibles for Furnace at a Great Refractory Ceramic Plates

These High Pureness Alumina Ceramic Watercraft Pots and Crucible Plates are developed hard for your heater. They deal with severe heat, up to 1750 ° C. This is possible because of the unique product. High purity alumina fireclay is the secret. It provides exceptional thermal shock resistance. Your crucibles will not break quickly under fast temperature adjustments.

Durability is a significant advantage. These crucibles last much longer than cheaper options. You save cash over time. They withstand chemical strike well. This suggests less responses with your examples or thaws. Your outcomes remain pure. The smooth surface coating is very important as well. It prevents sticking. Cleaning up is simpler. Taste contamination is minimized.

The boats and plates can be found in basic dimensions. Common sizes are available. Personalized forms are feasible if needed. They operate in numerous furnace kinds. Tube heating systems, box heating systems, kilns – all are suitable. Handling samples is uncomplicated. Thawing steels, sintering powders, warmth dealing with products – these are common uses.

Thermal security is impressive. Constant performance is ensured. Warmth disperses equally throughout the crucible. This avoids locations. Your processes run reliably. The product is really dense. Porosity is very little. This prevents gases or fluids dripping via. Your heating system remains cleaner. Upkeep is less constant.

These refractory ceramic plates are necessary laboratory devices. They supply trusted high-temperature assistance. Assume crystal growth, progressed porcelains work, metallurgical screening. Their stamina supports hefty loads. Thermal biking causes very little wear. They are a smart financial investment for requiring applications.

(High Purity Alumina Ceramic Boat Pot High Temperature Fireclay Crucibles for Furnace at a Great Refractory Ceramic Plates)

Applications of High Purity Alumina Ceramic Boat Pot High Temperature Fireclay Crucibles for Furnace at a Great Refractory Ceramic Plates

High pureness alumina ceramic watercrafts manage requiring heater job. These crucibles withstand extreme heat well. They withstand temperature levels near 1800 ° C quickly. Their incredibly high pureness matters most. We use over 99.6% pure alumina. This protects against contamination of sensitive products inside. The ceramic surface area remains smooth and non-reactive. It does not communicate with chemicals or liquified steels. This keeps your examples pure.

These boats are crucial in semiconductor manufacturing. They hold silicon wafers safely during high-temperature actions. The alumina will not include unwanted aspects. Lab analysis needs trusted crucibles as well. These watercrafts offer regular results. They sustain duplicated heating and cooling cycles without breaking. Thermal shock resistance is excellent.

Metallurgy utilizes these crucibles for melting precious metals or specialized alloys. The product deals with liquified steel without breaking down. Our crucibles provide lengthy life span. This conserves cash on replacements. They are dimensionally secure. This suggests they maintain their form under extreme warmth. Exact sample positioning remains feasible.

Our refractory ceramic plates sustain these boats. They also deal with high warm straight. The plates supply secure surfaces inside heaters. Making use of both products together produces a durable arrangement. We make these items for professionals needing reputable efficiency. They address problems with sample pureness and crucible failing. Integrity under warm stress and anxiety is ensured. High pureness alumina ceramic watercrafts and plates are important furnace tools.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Purity Alumina Ceramic Boat Pot High Temperature Fireclay Crucibles for Furnace at a Great Refractory Ceramic Plates

What temperatures can these alumina ceramic boats handle?

They handle extreme heat. They work up to 1750°C (3182°F). This makes them perfect for furnace work. They keep their shape and strength. They won’t soften or slump.

How pure is the alumina material?

The alumina is very pure. It’s over 99% pure. This high purity matters. It stops unwanted stuff from getting into your materials during heating. It gives clean results.

Can they handle sudden temperature changes?

Yes, they resist thermal shock well. They won’t crack easily if cooled fast. This is important for many lab and production steps. You heat and cool things quickly sometimes.

How long do these crucible boats last?

They last long. Their high purity and strong build fight wear. They resist chemical attack. They resist erosion from molten stuff. You get many uses from each boat. This saves money over time.

How do I clean them after use?

Cleaning is simple. Let them cool completely first. Then use water or a mild acid wash. Avoid harsh abrasives. Scrubbing hard can damage the surface. Gentle cleaning works best.

(High Purity Alumina Ceramic Boat Pot High Temperature Fireclay Crucibles for Furnace at a Great Refractory Ceramic Plates)

REQUEST A QUOTE

RELATED PRODUCTS

SINTYRON Unglazed Rectangular Alumina Ceramic Combustion Boat Laboratory Crucible for Melting

High Temperature Resistant Square Alumina Ceramic Boat With Large Capacity

Al2O3 Alumina Combustion Boat With Lid , Rectangle Alumina Sagger Ceramic Boats Crucible

High Working Temperature Rectangle Arc Boat Various Shape Supply 99.6% Alumina Ceramic Crucible Lid Available for Laboratory

Alumina Boat 115*30*20mm, Al2O3 Ceramic Boat Crucible