Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

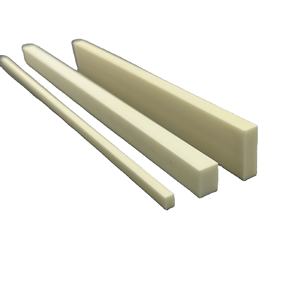

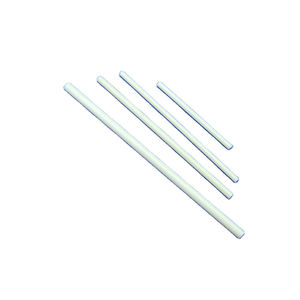

Overview of High Temperature Custom Made Alumina Zirconia Precision Ceramic Rod Pin bar

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of High Temperature Custom Made Alumina Zirconia Precision Ceramic Rod Pin bar

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of High Temperature Custom Made Alumina Zirconia Precision Ceramic Rod Pin bar

Right here’s the requirements introduction for our personalized alumina zirconia ceramic rod pins:

These precision poles handle extreme warm. They work reliably past 1500 ° C. Alumina zirconia provides terrific strength. It resists wear incredibly well. These pins will not easily chip or crack. We make them to your exact dimensions. Diameters range from 1mm to 50mm. Sizes rise to 500mm. Tighter dimensions are feasible. Tell us your needed tolerances. We commonly hit ± 0.1 mm or much better. Surface area surface issues for efficiency. We achieve really smooth surface areas. Common Ra is 0.4 μm. We can make it smoother if needed.

Electric insulation is a vital function. These rods obstruct present entirely. They are ideal for electrical usages. Chemical resistance is very high. Acids and alkalis won’t harm them. Bases do not impact them either. This product deals with thermal shock. Abrupt temperature adjustments are great. It increases really little with warmth. Dimensional security is excellent. The poles remain right and real. Long-term dependability is ensured.

We offer different alumina zirconia mixes. Usual blends are 80/20 or 70/30. The ratio affects residential or commercial properties. Greater zirconia increases sturdiness. Higher alumina enhances firmness. Review your application needs. We help choose the very best mix. Personalized forms are also possible. Grooves, strings, openings are alternatives. Unique end therapies are offered. Inform us your details design. We generate small and large batches. Prototype runs rate too.

These pins suit lots of tough jobs. They operate in furnace components. Semiconductor processing utilizes them. Welding tools needs them. Aerospace parts rely upon them. Medical devices benefit from them. Any kind of high-wear location fits them.

Applications of High Temperature Custom Made Alumina Zirconia Precision Ceramic Rod Pin bar

High temperature personalized made alumina zirconia accuracy ceramic rod pin bars tackle laborious normal materials can’t handle. They fix troubles in truly hot, demanding factory settings. Metal pins warp. Steel pins melt. Steel pins wear fast under stress and anxiety. These ceramic pins supply a far better remedy.

Factories utilize them widely. Welding equipment needs parts guiding warm wires properly. Alumina zirconia pins do this task flawlessly. They handle the extreme warmth near the welding arc. They remain dimensionally stable. This makes certain exact cord feeding every single time.

Electronic devices producing relies on them also. Procedures like brazing and sintering develop extreme heat. These ceramic pins placement components specifically inside high-temperature ovens. They do not carry out electricity. This prevents brief circuits. They resist chemical assault from fluxes or gases.

Glass manufacturing is another essential location. Handling liquified glass calls for incredible heat resistance. These ceramic pins function inside heating systems and creating devices. They manage warm glass sheets or overview developing tools. Their smooth surface avoids sticking. They endure thermal shock from quick temperature adjustments.

Customization makes these pins added valuable. Suppliers need specific dimensions, forms, and surface coatings. Perhaps a special size is called for. Maybe an unique idea geometry enhances a procedure. Personalized construction delivers the precise component required. This guarantees ideal fit and function in complex equipment.

The blend of alumina and zirconia gives special advantages. Alumina supplies great hardness and wear resistance. Zirconia adds extra durability and thermal shock resistance. With each other they produce a product far more powerful than basic porcelains under warmth and anxiety. This combination extends service life substantially.

These ceramic rods supply regular performance. They maintain limited tolerances even after long exposure to warm. This integrity reduces devices downtime. Manufacturing facilities avoid constant component replacements. Production lines maintain running efficiently.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Temperature Custom Made Alumina Zirconia Precision Ceramic Rod Pin bar

What are alumina zirconia precision ceramic rod pins?

These are custom-made rods and pins crafted from a special ceramic blend. This blend combines alumina and zirconia. It gives excellent heat resistance plus toughness. These components handle extreme conditions where metals fail.

Why choose alumina zirconia ceramic for rod pins?

This ceramic withstands very high temperatures easily. It resists wear exceptionally well. It doesn’t expand much with heat. It stays strong under heavy loads. It also resists chemical corrosion. These properties ensure long-lasting performance in tough settings.

Can you make these rods and pins to exact specifications?

Yes. We specialize in custom orders. You provide your precise requirements. We deliver rods and pins matching your exact dimensions. We meet tight tolerances. We accommodate specific shapes, lengths, diameters, and surface finishes. Tell us your needs.

How hot can these custom ceramic rods handle?

The alumina zirconia blend performs reliably at temperatures exceeding 1600°C (2912°F). It maintains its strength and shape. This makes it ideal for furnace parts, kiln furniture, and high-heat processing equipment. It won’t melt or deform easily.

What affects the price of custom ceramic rod pins?

Price depends mainly on the complexity. Simple, standard shapes cost less. Intricate designs or very tight tolerances increase machining time. Larger quantities usually lower the per-unit cost. Material purity and special surface treatments also influence the final price. We offer quotes based on your specific design.

REQUEST A QUOTE

RELATED PRODUCTS

Large Long Rustic Decorative Chrome Black 2 Pack 6.1 Inch Double Sliding Barn Balcony Door Pull Handles Lock Set for Wooden Door

1060 2014 5052 Aluminum Alloy Round Square Bar Ingot 1100 Grade 10mm 20mm 50mm Diameter 6061 T6 7075 5A06 Aluminum Bar Rod

Ceramic Alumina Ceramic Bar Pipe Rod Tubes

High Precision Zirconia Ceramic Bar Rod for Industry

Cheaper Low Black and White and Customized Aluminium Spacer Bar for Insulating Glass