Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

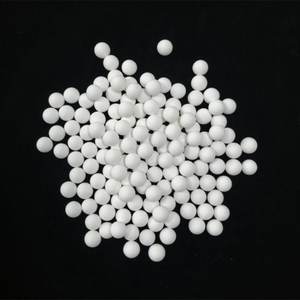

Overview of Efficiency Alumina Ceramic Ball 7MM 8MM 92% 95% Alumina Balls Wear Resistant Alumina Ceramic Ball for Grinding Media

Alumina balls are high-purity ceramic grinding media known for their exceptional hardness, wear resistance, and thermal stability. Ideal for industrial applications like milling, catalysis, and wear-resistant components.

Features of Efficiency Alumina Ceramic Ball 7MM 8MM 92% 95% Alumina Balls Wear Resistant Alumina Ceramic Ball for Grinding Media

High mechanical strength & durability

Excellent chemical & thermal stability

Superior wear & corrosion resistance

Available in various sizes & purity grades

Low contamination for precision processes

(Efficiency Alumina Ceramic Ball 7MM 8MM 92% 95% Alumina Balls Wear Resistant Alumina Ceramic Ball for Grinding Media)

Specification of Efficiency Alumina Ceramic Ball 7MM 8MM 92% 95% Alumina Balls Wear Resistant Alumina Ceramic Ball for Grinding Media

These alumina ceramic balls are difficult grinding media. They are available in 7mm and 8mm dimensions. You obtain two alumina content selections: 92% or 95%. The high alumina percent makes them very hard. They withstand wear very well. This matters a great deal for grinding work.

These balls deal with heavy grinding pressures. They last much longer than softer products. Utilizing them means much less downtime for substitutes. You save money with time. Their solidity minimizes contamination. Your item stays pure. This is essential for porcelains, chemicals, and minerals.

They function well in ball mills and attritors. The smooth surface area lessens item absorption. You obtain efficient grinding action. Regular size and thickness guarantee even grinding outcomes. The 7mm and 8mm sizes match various mill types and material needs.

Pick 95% alumina for the greatest wear resistance. It sets you back a bit a lot more. The 92% alumina provides great performance as well. It is an economical alternative. Both types exceed steel or pebbles in numerous applications. They excel in damp or dry grinding.

Mining operations utilize them for crushing ores. Ceramic factories grind resources with them. Paint makers attain great bit sizes. Chemical plants rely upon their inert nature. They withstand acids and antacids. These spheres manage tough problems. They keep grinding successfully. Minimized wear indicates lower maintenance prices. Your process runs smoother.

(Efficiency Alumina Ceramic Ball 7MM 8MM 92% 95% Alumina Balls Wear Resistant Alumina Ceramic Ball for Grinding Media)

Applications of Efficiency Alumina Ceramic Ball 7MM 8MM 92% 95% Alumina Balls Wear Resistant Alumina Ceramic Ball for Grinding Media

These alumina ceramic spheres address tough grinding troubles. They can be found in 7mm and 8mm dimensions. Made from 92% or 95% alumina, they are unbelievably hard. This firmness makes them extremely use immune. They last a lot longer than steel balls or all-natural stones. You save cash by changing them much less typically.

Their severe wear resistance is vital. They handle constant rubbing inside mills well. They maintain their sizes and shape gradually. This implies your grinding remains regular. You get reputable particle size results batch after set. You stay clear of downtime for regular media adjustments.

These rounds are chemically inert. They won’t respond with your materials. This avoids contamination. Your product remains pure. This is essential in sectors such as porcelains, paints, chemicals, and minerals handling. You get cleaner final products.

Contrasted to reduced quality ceramic balls, these 92% and 95% alumina rounds are denser. They are tougher. They resist chipping and damaging much better. This suggests fewer broken pieces in your mix. You get smoother procedure. Your mill liners likewise last longer because the balls are smoother.

These alumina rounds are really dense. They deliver strong effect pressure during grinding. This helps damage down materials effectively. You attain finer grinds much faster. Your procedure uses power much better. They function accurately in round mills, vibratory mills, and attritors. They take care of wet or completely dry grinding.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Efficiency Alumina Ceramic Ball 7MM 8MM 92% 95% Alumina Balls Wear Resistant Alumina Ceramic Ball for Grinding Media

What sizes do your alumina ceramic balls come in?

We offer two main sizes. These are 7mm and 8mm diameter balls. These sizes work well for many grinding jobs. People pick the size based on their equipment needs.

What does 92% and 95% alumina mean?

The numbers 92% and 95% show how much pure alumina is in the ball. A 95% ball has more alumina. More alumina usually means a harder ball. Harder balls often last longer in tough grinding work. Think about your grinding needs. Choose 92% for good performance. Choose 95% for maximum wear resistance.

Why choose alumina ceramic balls over other materials?

Alumina ceramic balls are very hard. Hardness fights wear. They resist chemicals well. This means they won’t rust or corrode easily. They are also very dense. Density helps them grind efficiently. Steel balls wear down faster. Plastic balls aren’t hard enough for serious grinding. Alumina balls give you a good balance. They are strong, long-lasting, and efficient.

What are these balls mainly used for?

These alumina balls are grinding media. You put them inside mills. They crush and grind materials. Industries like ceramics, paints, and chemicals use them a lot. They grind minerals, pigments, and powders. They work well in ball mills and vibratory mills. They are good for making things smooth and fine.

How are the balls packaged?

We pack the balls carefully. We use strong plastic bags. These bags go inside tough woven sacks. This double packing protects the balls during shipping. The bags keep the balls clean. The sacks prevent rips and spills. You get your order safe and ready to use.

(Efficiency Alumina Ceramic Ball 7MM 8MM 92% 95% Alumina Balls Wear Resistant Alumina Ceramic Ball for Grinding Media)

REQUEST A QUOTE

RELATED PRODUCTS

3mm 5mm 6mm 10mm 92% Alumina Ball Ceramic Grinding Beads Ball

4mm 5mm 10.5mm 12.7mm 13mm 16mm Alumina Ceramic Ball 92% 99% Aluminum Oxide Ball

3mm 6mm 9mm 25mm 65% Al2O3 Heat Storage Ceramic Ball Alumina Ball

Cushion Filler Polishing Custom Bio Alumina Ceramic Balls Alkaline Mineral Purification Water Filter Media Shower Ball Decor

92% Alumina Ceramic Grinding Ball 92% Alumina Grinding Balls Alumina Ball for Ceramic