Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

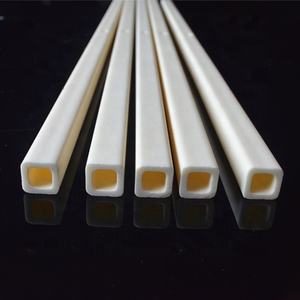

Overview of Precision Customized Drilling Grinding Alumina Ceramic Porous Stick bar Rod

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of Precision Customized Drilling Grinding Alumina Ceramic Porous Stick bar Rod

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of Precision Customized Drilling Grinding Alumina Ceramic Porous Stick bar Rod

These precision alumina ceramic porous stick bars offer custom solutions for demanding grinding and drilling tasks. Manufacturers shape high-purity alumina ceramic into rod forms. This material is very strong. It withstands extreme heat effectively. It resists chemical corrosion well. The ceramic structure features controlled porosity. This means tiny holes exist throughout the material. These holes act like channels. They allow coolant or air to flow freely during use. This flow is critical. It prevents overheating. It removes debris efficiently. It keeps the work surface clean.

Each rod undergoes precision grinding. This achieves exact dimensions. Tolerances are exceptionally tight. This ensures consistent performance. The surface finish is very smooth. This minimizes friction. It reduces wear on the rod. It also improves the finish on your workpiece. Customization options are extensive. You specify the diameter you need. You specify the exact length required. You can choose the pore size distribution. You can choose the precise porosity level. This tailoring matches your specific application perfectly.

These ceramic rods excel in precision grinding operations. They are ideal for fine drilling applications. Industries like aerospace use them. Semiconductor manufacturing relies on them. Medical device production utilizes them. They provide stable, reliable support. They maintain dimensional stability under stress. They last a long time. They offer consistent results batch after batch. They are a dependable choice for high-accuracy machining. They improve process efficiency significantly. They enhance product quality noticeably.

Applications of Precision Customized Drilling Grinding Alumina Ceramic Porous Stick bar Rod

Precision customized drilling grinding alumina ceramic porous stick bar rods solve tough problems. These rods are made from high-purity alumina. This material is very hard. It resists heat and chemicals well. The porous structure is key. It allows coolant or air to flow through during drilling or grinding. This keeps things cool. It also clears away debris efficiently.

Manufacturers need precise holes or surfaces. These rods deliver that precision. Electronics companies use them constantly. They drill tiny, exact holes in circuit boards. The ceramic doesn’t conduct electricity. This is vital. Aerospace factories rely on them too. They grind complex shapes on tough engine parts. The rods withstand high temperatures without wearing out fast.

Medical device makers need absolute cleanliness. These alumina rods are perfect. They are inert. They don’t contaminate sensitive implants during fine machining. They grind and drill biocompatible materials reliably. The porous design helps maintain sterile conditions. Automotive suppliers use them for grinding fuel injector nozzles. Precision here is critical for engine performance. The rods offer long life and consistent results.

Optics and semiconductor industries demand extreme accuracy. These ceramic rods grind lenses and silicon wafers. They create ultra-smooth finishes. They maintain tight tolerances. The customizable size and porosity are major advantages. Users get rods made exactly for their machine and task. This reduces waste. It improves overall efficiency. The rods last much longer than metal tools. They save money over time. They perform consistently under heavy use.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Precision Customized Drilling Grinding Alumina Ceramic Porous Stick bar Rod

Here are 5 FAQs about Precision Customized Drilling Grinding Alumina Ceramic Porous Stick bar Rod:

What exactly is this alumina ceramic porous rod?

This is a special ceramic part. It’s made mainly from alumina (aluminum oxide). The material has tiny holes throughout it. We call this porous. We make these rods in precise shapes and sizes for specific jobs. They are hard. They resist heat and chemicals well. They work well for grinding or drilling.

Why use porous alumina ceramic for these rods?

Porous alumina has unique benefits. The tiny holes let liquids or air pass through. This is vital for jobs needing flow or filtration. Alumina ceramic itself is very strong. It handles high temperatures. It doesn’t wear down easily. It resists corrosion. These properties make it reliable for tough industrial tasks.

Can I get these rods made to my exact specifications?

Yes. We specialize in custom orders. Tell us the dimensions you need. Tell us the hole size (pore size). Tell us the hole amount (porosity level). We can also adjust the alumina purity. We can make the rod surface smooth or rough. We meet your specific drilling or grinding requirements.

Where are these porous alumina rods typically used?

These rods have many industrial uses. They are common in precision grinding tools. They work well for fine drilling applications. People use them as filters for hot liquids or gases. They serve as diffusers for air or liquids. They are found in chemical processing. They appear in semiconductor manufacturing. They work in aerospace parts. They are good wherever you need a hard, porous, heat-resistant material.

Are there special handling considerations for these rods?

Handle them carefully. Alumina ceramic is hard. It can also be brittle. Avoid dropping them. Avoid hitting them hard. Protect them from sudden temperature shocks. Extreme rapid heating or cooling might cause cracking. Store them securely. Keep them from knocking against each other. Use them within their rated temperature and pressure limits.

REQUEST A QUOTE

RELATED PRODUCTS

Aluminum, Carbon Steel Square Bar Made of Mild Steel and Solid Steel

Stock Solid 3-500mm 2017 2024 3003 3A21 5052 5083 6061 6063 T6 T4 Round Alloy Aluminum Rod Bar

Custom Color Barbell Bar Competition Weightlifting Barbells Ceramic Coated Straight Powerlifting Barbell

Diamond Polishing 99% AL2O3 Bar Alumina Ceramic Rod

99 99.5 Alsint Alumina Ceramic Grinding Drilling Long Bar Alumina Ceramic Stick