Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

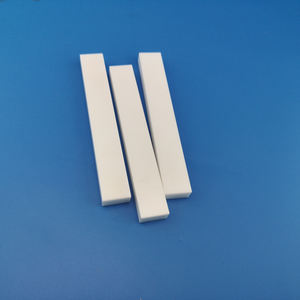

Overview of 99% Alumina Ceramic Friction Disc Industrial Ceramic Export Plate Working Sheet for Barmag Textile Spare Part Machine

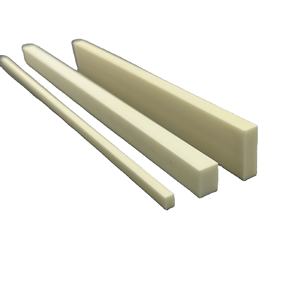

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of 99% Alumina Ceramic Friction Disc Industrial Ceramic Export Plate Working Sheet for Barmag Textile Spare Part Machine

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of 99% Alumina Ceramic Friction Disc Industrial Ceramic Export Plate Working Sheet for Barmag Textile Spare Part Machine

Here’s what you need to know about our 99% Alumina Ceramic Friction Discs. These are the essential plates used in Barmag textile machinery. They are built tough for demanding industrial settings. The core material is 99% pure alumina ceramic. This high purity delivers critical performance. These discs resist wear incredibly well. They last much longer than many other materials. This means fewer replacements. It means less machine downtime.

The discs handle high heat very effectively. Temperature changes won’t easily crack them. This stability is vital for consistent friction performance. Surface friction levels are carefully controlled. This precise control is crucial for smooth textile processing. It prevents yarn damage. It ensures reliable machine operation.

We make these discs to exact specifications. They fit Barmag machines perfectly. We offer various standard diameters and thicknesses. Custom sizes are possible too. Just tell us your machine model. We can supply the right plate. The surface finish is smooth and consistent. This avoids snagging delicate textile fibers. The discs are very hard. They resist scratching and surface damage. This hardness also fights chemical corrosion. Common machine fluids won’t degrade them.

These alumina ceramic plates are key spare parts. They replace worn friction elements in Barmag units. Using high-quality ceramic improves overall machine efficiency. It reduces maintenance frequency. It lowers long-term operating costs. Textile producers rely on this performance. Our export-grade plates meet global quality standards. They are ready for shipment worldwide.

Applications of 99% Alumina Ceramic Friction Disc Industrial Ceramic Export Plate Working Sheet for Barmag Textile Spare Part Machine

99% alumina ceramic friction discs serve critical roles in textile machinery, especially Barmag spare parts. These industrial ceramic plates handle intense friction and heat during high-speed yarn processing. Their exceptional hardness prevents wear. This hardness means the discs last much longer than metal alternatives. Textile factories face constant operation. Downtime costs money. These alumina sheets reduce machine stops for maintenance.

The material withstands temperatures exceeding 1500°C. Heat buildup is common in fast-moving friction zones. Alumina stays stable. Its thermal shock resistance prevents cracking from sudden temperature changes. Water or chemicals sometimes contact machine parts. Alumina ceramic resists corrosion. This property ensures consistent performance in varied textile mill conditions.

Low friction is essential. The ceramic surface provides smooth, reliable engagement. This gives precise control over yarn tension. Consistent tension improves yarn quality. Production runs become more reliable. Fewer breaks occur. Operators spend less time fixing problems.

These export-grade ceramic plates fit precisely into Barmag friction disc assemblies. Exact dimensions are crucial. Proper fit ensures optimal function and safety. The discs maintain their shape and surface integrity under heavy loads. This dimensional stability guarantees predictable friction behavior over time.

Using 99% alumina ceramic translates directly to lower operating costs. Replacement frequency drops significantly. Energy efficiency improves due to the material’s inherent properties. Factories save money on parts and power. Production output increases because machines run longer without interruption. Reliability is key in competitive textile manufacturing. These ceramic components deliver that reliability.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 99% Alumina Ceramic Friction Disc Industrial Ceramic Export Plate Working Sheet for Barmag Textile Spare Part Machine

What’s this alumina ceramic friction disc for?

It replaces worn parts in Barmag textile machines. These discs handle friction. They control yarn tension during spinning. The ceramic material withstands constant rubbing. It keeps machines running smoothly.

Why use 99% alumina ceramic?

High purity alumina is extremely hard. It resists wear much better than metal or plastic parts. This ceramic doesn’t deform under high pressure. It lasts much longer. You get fewer breakdowns. Production stays more reliable.

Will it fit my specific Barmag machine model?

Yes. These discs are made precisely for Barmag spares. We produce them to match original part dimensions exactly. Provide your machine model number. We confirm the correct plate size and shape. Fit is guaranteed.

How do I install this ceramic plate?

Installation is straightforward. Remove the old, worn disc. Clean the mounting area thoroughly. Place the new ceramic plate carefully. Ensure it sits flat and secure. Tighten any fasteners evenly. Refer to your machine manual. Follow standard safety procedures.

How long will it last?

Lifespan depends on operating conditions. Expect significantly longer service than original parts. The 99% alumina resists abrasion intensely. Typical use shows several times the lifespan of standard components. Proper installation and avoiding impacts help maximize durability.

Where can I get genuine replacements?

We specialize in these industrial ceramic export plates. We supply directly to textile factories worldwide. Our production meets strict quality standards. Contact us with your requirements. We provide quotes quickly. Reliable shipping is arranged.

REQUEST A QUOTE

RELATED PRODUCTS

99 Alumina High Temperature Resistant Ceramic Arc Ceramic bar

High Precision Customized ZTA Al2O3 Alumina ZrO2 Zirconia Ceramic Rod bar Ceramic Plunger

96% Al2O3 Ceramic Round Bar and Alumina Shaft

Industrial heating alumina ceramic rods/Al2O3 bar

Factory Supplying Extruded Aluminium 6061 6063 6082 7075 Aluminium square bar