Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

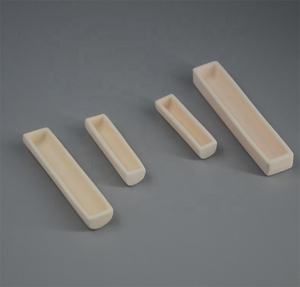

Overview of High Temperature Alumina Ceramic Crucible Boat for Melting or Analyzing Metal

High Temperature Alumina Ceramic Crucible Boat for Melting or Analyzing Metal is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of High Temperature Alumina Ceramic Crucible Boat for Melting or Analyzing Metal

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(High Temperature Alumina Ceramic Crucible Boat for Melting or Analyzing Metal)

Specifications of High Temperature Alumina Ceramic Crucible Boat for Melting or Analyzing Metal

This alumina ceramic crucible boat deals with severe heat for melting or testing metal. It’s made from over 99% pure alumina. This product resists extremely high temperatures. You can utilize it securely as much as 1750 ° C. It won’t melt or soften. The boat form is steady. It holds molten steel securely.

It battles chemical strike well. Acids and bases won’t harm it quickly. Molten metals like gold, silver, copper, or platinum will not react with it. This indicates your metal stays pure. You obtain precise evaluation results. No contamination occurs.

Thermal shock resistance is solid. You can warm it quickly. You can cool it quick. It will not split quickly. This sturdiness is necessary for lab work. It conserves time. It also makes the watercraft last much longer. Duplicated heating and cooling cycles are fine.

Its surface area is extremely smooth. This stops product from sticking. Cleaning up is basic after usage. The framework is thick. This protects against leakages. It also quits gases from getting in. Your process remains managed.

We offer basic dimensions. Usual choices are 50mm, 75mm, and 100mm long. Width and height vary. Custom-made sizes are feasible as well. Wall thickness suffices for strength. It handles rough problems. The boat offers dependable efficiency. It stands up to daily use in furnaces.

(High Temperature Alumina Ceramic Crucible Boat for Melting or Analyzing Metal)

Applications of High Temperature Alumina Ceramic Crucible Boat for Melting or Analyzing Metal

High temperature alumina ceramic crucible watercrafts manage severe heat remarkably well. They endure temperatures over 1700 ° C dependably. This makes them essential devices for melting steels. Individuals utilize them for melting gold, silver, copper, and other valuable or base steels. They are likewise vital in labs for examining steel samples. Their pureness matters greatly. They have very few contaminations. This stops contamination of the liquified metal or the sample being analyzed. You get precise outcomes every time. Their chemical resistance is one more big plus. They stand up to strike from the majority of molten steels and changes. This makes sure the crucible watercraft itself doesn’t introduce unwanted elements. The product is really secure. It doesn’t fracture or warp quickly under sudden temperature level modifications. This thermal shock resistance is vital for repeated heating and cooling down cycles. Employees value their resilience. They last with lots of melting or evaluation runs. This conserves cash gradually. Their smooth surface area allows very easy elimination of strengthened metal slugs. Clean-up is easy. They see hefty usage in foundries for small-scale melting. Jewelers depend on them for crafting precious metal pieces. Laboratories rely on them for exact steel structure evaluation. Crystal growers also utilize them to hold liquified materials. Their constant efficiency is relied on worldwide. They use a reliable solution for demanding high-temperature tasks.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Temperature Alumina Ceramic Crucible Boat for Melting or Analyzing Metal

What temperature can these crucible boats handle?

Alumina ceramic crucible boats work reliably up to 1750°C (3182°F). This suits most metal melting and analysis jobs. They keep their shape and strength at these high heats. Check the exact grade for its specific limit.

Can they handle fast temperature changes?

Yes, they resist thermal shock well. You can heat them up fast or cool them down fast. This matters for repeated use in furnaces or rapid cooling tests. They are less likely to crack than some other materials.

Do they react with molten metals?

Alumina ceramic is highly inert. It resists attack from many molten metals and alloys. This includes metals like gold, silver, copper, and platinum. It also works well with various fluxes and slags. Always confirm compatibility with your specific metal first.

How long do these crucibles last?

Lifespan depends heavily on use. Factors include peak temperature, heating/cooling speed, and the metal type. Gentle handling extends their life. They withstand repeated thermal cycling better than cheaper materials. Expect many uses under normal conditions.

How should I clean them after use?

Remove cooled metal carefully. Avoid mechanical shock. Use dilute acid baths for tough residues. Hydrochloric acid (HCl) often works well. Rinse thoroughly with water after cleaning. Ensure they are completely dry before reheating to prevent cracking.

(High Temperature Alumina Ceramic Crucible Boat for Melting or Analyzing Metal)

REQUEST A QUOTE

RELATED PRODUCTS

100mmX20mmX20mmHigh Temperature Trapezoidal Shape Ceramic Alumina Boat Crucible for Melting Furnace

Alumina Advanced Ceramics Cylindrical Refractory Melting Ceramic Boat Crucible for Melting Gold,

In Stock 99% Alumina Al2o3 Corundum Ceramic Boat for Furnace Sintering

Laboratory Used Alumina Ceramic Combustion Boat

High Purity High Temperature square 99 Alumina Ceramic Boat for Thermal Analysis