Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

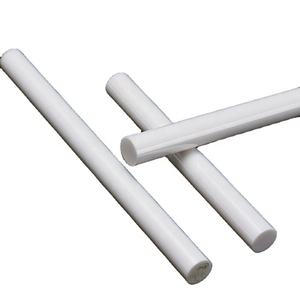

Overview of 99% Al2O3 Alumina Ceramic Tube Aluminium Oxide Ceramic Plunger Pipe Roller for Industrial Application Parts

99% Al2O3 Alumina Ceramic Tube Aluminium Oxide Ceramic Plunger Pipe Roller for Industrial Application Parts is engineered from 99%+ pure aluminum oxide (Al₂O₃), delivering unmatched durability and precision for demanding industrial applications. Designed to operate in extreme conditions, these plungers excel in high-wear, high-temperature, and corrosive environments, making them perfect for pumps, valves, fuel injection systems, and chemical processing equipment.

Features of 99% Al2O3 Alumina Ceramic Tube Aluminium Oxide Ceramic Plunger Pipe Roller for Industrial Application Parts

Superior Wear Resistance – Outlasts metal plungers in abrasive environments.

High-Temperature Stability – Maintains integrity up to 1600°C.

Corrosion & Chemical Resistance – Immune to acids, alkalis, and solvents.

Extreme Hardness (Hv 1500+) – Minimizes friction and extends service life.

Precision Machined – Tight tolerances for smooth, leak-free operation.

Customizable Designs – Available in various diameters, lengths, and surface finishes.

(99% Al2O3 Alumina Ceramic Tube Aluminium Oxide Ceramic Plunger Pipe Roller for Industrial Application Parts)

Specifications of 99% Al2O3 Alumina Ceramic Tube Aluminium Oxide Ceramic Plunger Pipe Roller for Industrial Application Parts

Right here are the specs for our 99% Al2O3 alumina ceramic tubes, bettors, pipelines, and rollers. These components are constructed for difficult industrial tasks. They manage problems various other products can not.

The main material is 99% aluminum oxide ceramic. This high purity makes the components extremely strong. They resist use extremely well. Hardness is near the top of the scale. This firmness means components last a long time. They maintain their shape under stress. Abrasive products trigger little damage.

Warmth resistance is a crucial function. These parts work great in really hot atmospheres. Temperatures as much as 1700 ° C (3092 ° F) are no worry. Unexpected temperature level adjustments will not split them easily. This makes them perfect for heating systems, kilns, and high-heat equipment.

Electrical insulation is an additional major advantage. Alumina ceramic does not conduct power. It is exceptional for protecting components in electronic devices. It protects against brief circuits. It functions accurately in high-voltage situations.

Chemical security is very important. These components withstand assault from many acids and alkalis. Rust is rarely a problem. They work well in chemical handling equipment. Harsh solvents generally don’t influence them.

The surface area is extremely smooth. Friction is reduced. This is good for plungers and rollers. It lowers wear on mating components. It helps things slide smoothly. Lubrication demands are often reduced.

These parts are dimensionally stable. They do not expand much with warmth. Precision sizing is possible. Tolerances can be held securely for equipment. Performance remains consistent.

Common commercial usages include furnace tubes, thermocouple defense sheaths, pump bettors, overview rollers, insulating bushings, wear-resistant linings, and sensor housings. They are located in steel handling, chemical plants, power generation, semiconductor tools, and heavy equipment. They change metal components that break as well quickly.

(99% Al2O3 Alumina Ceramic Tube Aluminium Oxide Ceramic Plunger Pipe Roller for Industrial Application Parts)

Applications of 99% Al2O3 Alumina Ceramic Tube Aluminium Oxide Ceramic Plunger Pipe Roller for Industrial Application Parts

These 99% alumina ceramic tubes, plungers, pipes, and rollers are tough commercial parts. They take care of severe conditions regular products fall short in. High pureness light weight aluminum oxide makes them special. This product supplies exceptional performance.

Warmth is no worry for these porcelains. They stand up to temperatures over 1700 ° C. This makes them best inside furnaces, kilns, and high-heat handling equipment. They serve as thermocouple protection tubes, insulating sleeves, and heating system liners. They maintain warmth included and secure delicate parts.

Their firmness is exceptional. Alumina ceramic is a lot harder than steel. This gives excellent wear resistance. Parts last a lot longer in rough settings. We see bettors in pumps taking care of slurries or powders. Tubes guide unpleasant cables or fibers. Rollers withstand constant friction in conveyors or goal. They withstand erosion and scratching.

Chemical strike is one more strength. Alumina resists most acids and alkalis well. It does not rust or corrode like steels. These components work accurately in chemical plants, labs, and harsh atmospheres. Bettors secure pumps moving aggressive fluids. Pipes carry destructive chemicals safely. They maintain integrity where steels fail.

Electric insulation is vital too. Alumina ceramic doesn’t conduct electrical energy. It protects properly at heats. This is essential for electrical feedthroughs, insulators in heaters, and sensing unit housings. They prevent short circuits and isolate elements securely.

These components are dimensionally stable. They don’t warp or broaden much with warmth. This ensures specific alignment and fit in machinery. Tight resistances matter for plungers in metering pumps or rollers assisting products. Stability guarantees constant efficiency.

Industries depend on these alumina elements daily. Semiconductor producing uses them for wafer handling and furnace tubes. Fabric machinery uses ceramic guides and rollers. Medical gadgets use them for their biocompatibility and sterility. Food processing gain from their inert, non-contaminating nature. Anywhere requiring warm, wear, deterioration, or electrical resistance exists, these porcelains provide dependability.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 99% Al2O3 Alumina Ceramic Tube Aluminium Oxide Ceramic Plunger Pipe Roller for Industrial Application Parts

What material are these tubes and plungers made from?

They use 99% aluminum oxide ceramic. This high purity makes them very hard and durable. It also means they resist chemicals well.

How hot can these ceramic parts handle?

They work fine up to 1600 degrees Celsius. This high heat tolerance is much better than most metals. They won’t melt or deform easily under extreme heat.

Why choose alumina ceramic over metal?

Alumina ceramic is much harder than steel. This hardness means it wears down very slowly. It also resists corrosion much better than metal parts. You get longer life and less replacement.

Can you make custom shapes?

Yes, we can machine custom sizes and shapes. This includes specific diameters, lengths, or end details. Complex shapes cost more due to extra machining time.

Are these parts fragile?

Alumina ceramic is very strong under pressure. It is brittle though. Handle it carefully. Avoid sharp impacts or sudden temperature changes. Proper handling prevents chips or cracks.

(99% Al2O3 Alumina Ceramic Tube Aluminium Oxide Ceramic Plunger Pipe Roller for Industrial Application Parts)

REQUEST A QUOTE

RELATED PRODUCTS

99 High Purity Alumina Ceramic Piston Plunger for Valve

High Purity 99% Alumina Aluminium Oxide Advanced Ceramic Pump Plunger Tube Pipe Sleeve

Ceramic 99% Al2o3 Alumina Plunger Pipe Piston

Insulating Alumina Ceramic Plunger for Filling Metering Dosing Pump Silicon Nitride Parts Welding Cutting Processing Services

High Precision Al2o3 Alumina Ceramic Piston Plunger for Pump Valve Ceramic Sleeve