Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

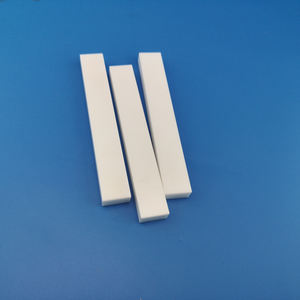

Overview of Custom Size High Quality Wear And Corrosion Resistant Alumina Ceramic Rod Needle bar

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of Custom Size High Quality Wear And Corrosion Resistant Alumina Ceramic Rod Needle bar

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of Custom Size High Quality Wear And Corrosion Resistant Alumina Ceramic Rod Needle bar

Required custom-sized alumina ceramic rods? We provide high-purity alumina ceramic pole needles. These rods are built challenging. They stand up to severe wear and harsh rust. Alumina content is high, generally 99.5%. This makes sure superb performance. Density is high also, around 3.9 g/cm FOUR. This makes the material extremely hard. Solidity is near HRA 88. That’s harder than many steels. Flexural stamina is strong, about 350 MPa. They deal with significant flexing force. Compressive stamina is also greater, over 2000 MPa. These rods sustain hefty lots. Thermal security is great. They work great as much as 1600 ° C. Electric insulation is exceptional. These rods won’t conduct electrical power. Chemical resistance is outstanding. Acids and antacid will not damage them. Many solvents are also not an issue. This makes them perfect for severe environments. They perform well in chemical plants. They are reliable in semiconductor tools. They are sturdy in clinical devices. Surface area surface is smooth. It can be very great, under Ra 0.2 µm. Reduced friction is an outcome. Put on is decreased. You choose the exact size. Diameter can range from 1mm to 30mm. Size can be approximately 500mm. Tighter resistances are feasible. We meet exact dimensional needs. These rods are really flexible. They are perfect for accuracy parts. They work as wear-resistant guides. They operate as insulating components. They act as probe needles. They are used in heater components. They are necessary in lab tools. Anticipate lengthy service life. Expect minimal maintenance. Anticipate dependable procedure. These alumina rods supply a durable solution. They await requiring applications.

Applications of Custom Size High Quality Wear And Corrosion Resistant Alumina Ceramic Rod Needle bar

Custom size high quality wear and rust resistant alumina ceramic rod needle bars are important parts. They solve hard troubles popular sectors. Alumina ceramic deals exceptional hardness. This product resists abrasive wear incredibly well. It stands up to continuous rubbing and scratching. These rods likewise deal with rust strongly. They deal with solid acids, harsh antacid, and salt services easily. The material won’t corrosion or deteriorate chemically. This combination is uncommon. Steels frequently fail here.

These ceramic rods excel in high temperature setups. They keep stamina and form even under extreme warmth. Thermal shock resistance is one more crucial benefit. They handle quick temperature level changes without cracking. Electrical insulation residential properties are outstanding. Alumina ceramic does not perform electricity. This is important for lots of electrical applications.

Producers generate these rods exactly. They personalize diameters and sizes to precise demands. Tight tolerances are standard. Surface area surfaces are smooth. This precision makes certain reputable efficiency in assemblies. Uniformity is ensured set after set.

Industries rely on these custom-made alumina rods. Semiconductor producing utilizes them as guides and components. Chemical handling employs them for pump shafts and valve stems. Textile equipment needs them for high-wear overviews. Clinical device manufacturers utilize them for accurate components. Oil and gas applications demand their deterioration resistance. Automotive sensing units benefit from their protecting residential properties. They act as robust thermocouple security tubes. These poles do where metals quickly fail. They last much longer, decreasing downtime and replacement prices.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Custom Size High Quality Wear And Corrosion Resistant Alumina Ceramic Rod Needle bar

You need custom-sized alumina ceramic rods. You have questions. We answer them here.

What sizes can you make? We make rods in many diameters and lengths. Tell us your exact requirements. We produce rods from very small diameters to larger ones. Lengths vary too. We focus on your specific needs.

Why choose alumina ceramic? Alumina ceramic is extremely hard. It resists wear exceptionally well. It also handles strong acids and bases without corroding. This material lasts much longer than metals in tough conditions. It saves you money on replacements.

Where can I use these rods? Use them anywhere you need a tough, non-corroding part. Common uses include guiding wires, as wear-resistant shafts, or as insulating components. They work well in chemical processing, textiles, electronics, and machinery. They handle high temperatures easily.

Are these rods fragile? Alumina ceramic is brittle like glass. Handle it carefully. Avoid sharp impacts or bending forces. Proper installation prevents breakage. Once installed correctly, it performs reliably under high stress and wear. We provide handling tips.

How do you ensure quality? We start with high-purity alumina powder. Our production uses precise molding and high-temperature sintering. Every rod undergoes strict checks. We measure dimensions accurately. We test hardness and strength. You get consistent, reliable parts.

REQUEST A QUOTE

RELATED PRODUCTS

Shullte Part Tonghong XHZ-150503 Retaining Needle Bar Palm Piece Webbing Machine Part Dropper for Shuttle Loom

Customized 170W/mk Aluminum Nitride Shaft Ceramic Electrical Device Rod bar

Factory Whole 1060 1070 PURE Aluminum Rectangular Flat Bar 10mm 8mm 6mm Aluminum Busbar

Aluminum Bar Aluminum Square Bar 1060 5052 5053 6061 Aluminum Round Bar

6mm 8mm 10mm Diameter Aluminum Round bar 6063