Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

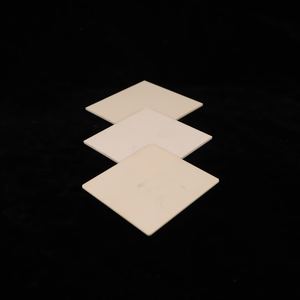

Overview of Structural Parts 95 99 Alumina Ceramic Substrate / Sheet / Plate / Board

Structural Parts 95 99 Alumina Ceramic Substrate / Sheet / Plate / Board is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of Structural Parts 95 99 Alumina Ceramic Substrate / Sheet / Plate / Board

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(Structural Parts 95 99 Alumina Ceramic Substrate / Sheet / Plate / Board)

Specification of Structural Parts 95 99 Alumina Ceramic Substrate / Sheet / Plate / Board

This item is 95% or 99% alumina ceramic. It’s a high-purity material. Individuals use it for structural components. These parts need stamina and security. The material is available in various kinds. You can get substrates, sheets, plates, or boards. The selection relies on your application.

Criterion dimensions are common. Normal sheets are 100x100mm or 150x150mm. Larger sizes like 200x200mm exist. Custom sizes are possible. Thickness matters a great deal. Usual densities range from 0.5 mm to 10mm. Thinner pieces are extra breakable. Thicker pieces manage even more tension. You choose density based on your demands.

Alumina ceramic is extremely tough. It withstands wear very well. This makes components last much longer. The material handles high warmth. It functions well up to 1600 ° C. This is good for warm settings. It additionally shields power. This avoids electrical currents. That’s important in electronics.

The surface coating is usually smooth. This aids with accuracy. Often a finer gloss is needed. The edges are clean. They are cut accurately. This ensures components fit appropriately. You can machine these ceramics. Machining demands special diamond tools. It’s done very carefully.

These alumina parts are trusted. They don’t corrode conveniently. Chemicals do not harm them a lot. They remain solid under pressure. They maintain their form at high temperatures. This makes them useful in numerous markets. Electronics use them for insulation. Heaters utilize them for warmth protection. Use parts utilize them for sturdiness.

(Structural Parts 95 99 Alumina Ceramic Substrate / Sheet / Plate / Board)

Applications of Structural Parts 95 99 Alumina Ceramic Substrate / Sheet / Plate / Board

Structural components made from 95% to 99% alumina ceramic are crucial in several demanding sectors. This product is incredibly hard. It stands up to wear incredibly well. This sturdiness makes it best for rough atmospheres. Alumina ceramic takes care of really high temperatures conveniently. It does not thaw or flaw under warm like metals commonly do. This thermal security is vital.

Semiconductor making relies heavily on alumina. It develops accuracy components inside wafer processing equipment. Alumina parts hold wafers firmly during etching and deposition actions. They provide electric insulation inside the equipments. Plasma can not easily harm these ceramic parts. This guarantees lengthy life span and constant manufacturing.

Laser systems also use alumina structural parts. It holds optical components stable. Alumina resists the extreme warm created by high-power lasers. This maintains the laser light beam precisely straightened. The ceramic’s smooth surface lessens light scattering. This safeguards sensitive optics nearby.

Industrial setups require solid electrical insulators. Alumina plates and boards serve this function accurately. They isolate high-voltage components safely. These insulators work in heating systems and various other hot locations. Steel insulators would certainly fail under these conditions. Alumina takes care of the warmth and voltage without damaging down.

Factories make use of alumina components and jigs. These hold parts during machining or heat therapy. Alumina withstands the sparks and warmth of welding. It doesn’t infect the workpiece. Alumina liners safeguard surfaces from rough products. This minimizes tools wear dramatically.

Dimension devices gain from alumina’s stability. It forms level, stiff bases for determines and sensors. This base does not warp with temperature modifications. So measurements remain accurate with time. Alumina is chemically inert too. It won’t react with most acids or solvents. This makes it secure for chemical handling equipment and lab setups.

Medical gadgets integrate alumina parts. Its biocompatibility is superb. Alumina components are located in diagnostic devices and medical tools. They provide electrical isolation and sterility. Research study labs make use of alumina plates and substratums. They sustain experiments requiring thermal stability and electric insulation. This product fixes numerous hard engineering issues.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Structural Parts 95 99 Alumina Ceramic Substrate / Sheet / Plate / Board

What exactly is 95-99% alumina ceramic?

It’s a very hard, dense material made mostly from aluminum oxide. Think of it like super-tough pottery. The 95% or 99% tells you how pure the aluminum oxide is. Higher purity usually means better performance, especially under heat or electrical stress. It costs more too.

Why pick alumina ceramic over metal or plastic?

Alumina handles extreme heat much better. It doesn’t melt or warp easily like plastic. It resists wear far longer than most metals. It doesn’t rust. It insulates electricity extremely well. It’s also very stiff and holds its shape under heavy loads. Use it where these things matter most.

What jobs need this alumina ceramic?

You see it inside high-temperature furnaces as shelves or liners. It carries electronic circuits needing insulation and heat control. It forms tough parts in pumps and valves fighting abrasion. It shields sensitive equipment. It builds precise jigs and fixtures in factories. Any place demanding strength, heat resistance, and electrical isolation uses it.

What sizes and shapes can you get?

Factories make it mostly as flat sheets or plates. Common thicknesses range from thin slices like 0.5mm up to thick blocks like 25mm or more. Standard sheets might be 100mm x 100mm, 200mm x 200mm, or even larger like 300mm x 300mm. Bigger sizes are possible. Factories can cut it to your exact rectangle or square. They can also drill holes or machine simple edges.

How do you handle and work with this material?

Handle it carefully. It’s hard but brittle, like glass. Dropping it or hitting it sharply can break it. Cutting or drilling needs diamond tools. Regular metal tools won’t work and might chip the ceramic. Tell the factory your exact needs upfront. They have special equipment to machine it cleanly before they ship it. Trying to cut it yourself later is difficult and risky.

(Structural Parts 95 99 Alumina Ceramic Substrate / Sheet / Plate / Board)

REQUEST A QUOTE

RELATED PRODUCTS

High Hardness Alumina Ceramic Al2O3 Ceramic Block Ceramic Plate

High Purity 99%High Temperature Resistance Alumina Ceramic Plate

Ceramic Plate 99.8% Alumina Ceramic Piece Disc

MCH Alumina Ceramic Heating Element Customized Ceramic Plate Piece for Semiconductor Chip Production Equipment

Alumina Ceramic Radiator / Ceramic Custom High Temperature Ceramic Plate