Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

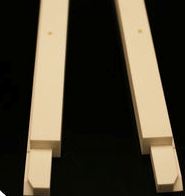

Overview of Aluminum Bar Aluminum Square Bar 1060 5052 5053 6061 Aluminum Round Bar

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of Aluminum Bar Aluminum Square Bar 1060 5052 5053 6061 Aluminum Round Bar

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of Aluminum Bar Aluminum Square Bar 1060 5052 5053 6061 Aluminum Round Bar

Light weight aluminum bars provide toughness without too much weight. You discover them in square and round forms. Typical alloys include 1060, 5052, 5053, and 6061. Each kind has various staminas. Select the alloy based on your job requires.

Light weight aluminum 1060 is really pure. It deals with creating easily. It withstands rust well. Utilize it for chemical tools or reflectors. It bends and shapes without trouble. It’s not the best alloy though.

Alloy 5052 is more powerful than 1060. It handles saltwater deterioration much better. It’s popular for aquatic components. Think boat fittings or fuel containers. It also functions well for sheet metal projects. It machines halfway decent.

Alloy 5053 is rather comparable to 5052. It beams in marine setups as well. It commonly enters into boat hulls or railings. It welds perfectly. Its strength is good for architectural pieces subjected to weather.

Alloy 6061 is widely used. It uses exceptional stamina. It makers very well. You see it in aircraft components, bike frames, and machinery. It welds quickly. It reacts well to warm therapy for added firmness. It’s a really versatile selection.

Square light weight aluminum bars have level sides. They fit nicely into structures or structures. Round aluminum bars work for shafts or rollers. Both shapes come in basic sizes. Typical thicknesses range from 1/4 inch approximately 6 inches or more. Lengths are often 12 feet, however custom cuts exist.

These bars fit numerous sectors. Building and construction uses them for assistances. Manufacturing facilities need them for equipment parts. Hobbyists construct projects with them. They withstand rust efficiently. They perform warm and electrical power well. They look clean and modern-day. Remember the alloy properties matter most. Match the product to the task’s demands. Stock dimensions are conveniently offered. You can order particular sizes as well.

Applications of Aluminum Bar Aluminum Square Bar 1060 5052 5053 6061 Aluminum Round Bar

Light weight aluminum bar stock can be found in many forms and alloys. Square bars and rounded bars prevail types. Various alloys fit various tasks. Aluminum 1060 is really pure. It supplies excellent corrosion resistance and great formability. People use 1060 for chemical devices or reflectors. It’s also great for basic manufacture where strength isn’t the primary worry.

Light weight aluminum 5052 is more powerful than 1060. It deals with seawater deterioration well. This makes 5052 popular for marine components. Believe boat installations or hull elements. It also sees usage in fuel storage tanks and general sheet metal job. Producers like its weldability and modest stamina.

Light weight aluminum 5053 is similar to 5052. It has slightly much better salt water deterioration resistance. People frequently pick 5053 for bonded marine frameworks. It does well in harsh atmospheres.

Aluminum 6061 is one of the most common general-purpose alloy. It supplies good strength and is very easy to device. You can bond it. People make use of 6061 for countless points. Building tasks use it for frames, sustains, and barriers. Factory turn it into gears, shafts, and fittings. The auto market uses it for parts and custom-made constructs. Hobbyists and do it yourself projects rely upon it also. The T6 temper is very typical for maximum toughness.

Square aluminum bars give level surfaces. This makes them suitable for structures, structures, and supports needing right angles. They offer security and are very easy to screw with each other. Round light weight aluminum bars work well for shafts, rollers, pins, and attractive components. Their form is good for rotating parts. Both shapes are widely available in these alloys.

Selecting the ideal light weight aluminum bar relies on the work. Take into consideration the needed strength. Think about rust direct exposure. Consider whether welding or machining is needed. Aluminum 1060 help fundamental, corrosion-prone jobs. Light weight aluminum 5052 and 5053 manage marine setups well. Light weight aluminum 6061 deals with demanding structural and mechanical jobs.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Aluminum Bar Aluminum Square Bar 1060 5052 5053 6061 Aluminum Round Bar

What are aluminum bars used for? Aluminum bars are common in construction. They make frames and supports. They are used in automotive parts. They work in machinery. They are good for DIY projects. They build furniture and decorations. What are the differences between 1060, 5052, 5053, and 6061 aluminum? 1060 is soft and easy to shape. It resists corrosion well. 5052 handles saltwater better. It is stronger than 1060. 5053 is like 5052 but stronger. 6061 is the toughest. It can be heat-treated. It is good for heavy structures. How do I pick the right alloy? Think about your project. Need strength? Choose 6061. Need corrosion resistance? Pick 5052 or 5053. Need easy bending? 1060 is best. Check cost too. 1060 is cheaper. Are aluminum bars strong? Yes. They are strong for their weight. 6061 is very strong. 5052 and 5053 are medium. 1060 is softer. They hold up in many uses. But steel is stronger. Can I weld these aluminum bars? Yes. Welding works for all. 6061 welds easily. 5052 and 5053 weld well too. 1060 is okay but needs care. Clean the metal first. Use the right filler.

REQUEST A QUOTE

RELATED PRODUCTS

99% Wear Resistance Al2O3 Square Alumina Ceramic Bar Industrial Ceramic Parts Application

Custom alumina high temperature ceramic bar/strips/blocks

Customized Industrial High Polish Wear Resisting 99 Al2o3 Alumina Ceramic Rod bar

Ceramic superfine capillary tube pipe rod bars

Factory s Customized 1050 1100 3003 5083 6061 6063 7075 Aluminum Alloy Bar Rod