Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

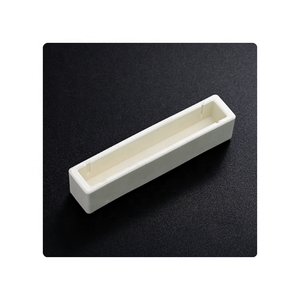

Overview of Corundum Alumina Ceramic Combustion Boat Unglazed

Corundum Alumina Ceramic Combustion Boat Unglazed is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of Corundum Alumina Ceramic Combustion Boat Unglazed

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(Corundum Alumina Ceramic Combustion Boat Unglazed)

Specifications of Corundum Alumina Ceramic Combustion Boat Unglazed

This Corundum Alumina Ceramic Burning Boat is unglazed. It’s made from high-purity alumina. This product offers superior performance. The boat stands up to severe warmth. Its optimum continuous use temperature gets to 1650 ° C (3000 ° F). It manages even higher temperature levels for short ruptureds. This makes it best for demanding lab job. Believe example ashing, flux blend, or high-temperature calcination.

The ceramic is exceptionally difficult. It stands up to wear and abrasion very well. Its surface area remains smooth through duplicated use. This unglazed coating offers excellent thermal conductivity. Warm transfers effectively through the boat. It additionally resists chemical attack. Acids and antacid will not conveniently harm it. This chemical inertness protects your samples. Contamination threats are low.

Thermal shock resistance is an additional key feature. The watercraft can deal with quick temperature modifications. Relocate from a warm heater to a cooler location is usually safe. Unexpected home heating or cooling will not easily fracture it. This sturdiness conserves cash. You obtain a longer service life from each boat.

Physical dimensions are standardized. Usual sizes are available. Regular lengths range from 50mm to 150mm. Sizes are usually in between 10mm and 30mm. Heights are normally around 10mm to 15mm. Custom-made sizes are feasible too. Check particular listings for precise dimensions. The boat’s shape is easy. It has a superficial, rectangle-shaped trough. This layout holds powders or little samples firmly.

(Corundum Alumina Ceramic Combustion Boat Unglazed)

Applications of Corundum Alumina Ceramic Combustion Boat Unglazed

Corundum alumina ceramic burning boats are unglazed. This makes them various. They are made from really pure alumina. This material handles severe warmth well. These watercrafts are difficult. They resist unexpected temperature level modifications. Thermal shock is no worry for them. They survive fast home heating and cooling down cycles. This is very important in actual labs and manufacturing facilities.

The unglazed surface area is vital. It remains porous. This allows gases to move easily during burning. Complete burning happens. Samples burn uniformly. Contamination risks are reduced. Glazed surface areas might trap gases or present contaminations. Unglazed avoids that. The harsh surface holds samples well. Powders or solids sit tight throughout handling and home heating.

These watercrafts are workhorses. Individuals use them for example preparation. Examining ash material in materials like coal or food is common. They are vital in loss on ignition examinations. Identifying organic matter web content relies on them. High temperature therapies need reputable containers. These watercrafts supply. Industries like cement, glass, and metallurgy depend upon them. Study laboratories utilize them daily. They hold samples safely inside tube heating systems or muffle heaters.

The high pureness alumina withstands chemical strike. Acids and antacids don’t quickly harm it. This makes sure example stability. Results remain exact. The watercrafts last a long time. They endure constant high warmth direct exposure. Replacing them less commonly conserves money and downtime. Their basic layout is useful. Cleaning is simple. Operators appreciate their integrity. They perform continually under demanding problems. Regular use entails temperature levels from 1000 ° C as much as 1600 ° C or perhaps higher often.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Corundum Alumina Ceramic Combustion Boat Unglazed

Here are 5 common questions about our Corundum Alumina Ceramic Combustion Boats (Unglazed):

What temperature can these combustion boats handle?

These boats withstand very high heat. They are rated for continuous use up to 1750°C (3182°F). They resist sudden temperature changes well. Don’t expose them to extreme cold immediately after high heat.

Are these boats resistant to chemicals?

Yes. The pure aluminum oxide material offers excellent chemical resistance. They handle most acids, alkalis, and solvents without damage. This makes them reliable for varied sample testing. Strong hydrofluoric acid and phosphoric acid can attack the material.

Why are the boats unglazed?

Unglazed surfaces prevent contamination. Glazes can sometimes react with samples or flake off at extreme temperatures. The unglazed ceramic provides a pure, inert surface for your materials. It ensures test results stay accurate.

How durable are these alumina boats?

They are very hard and strong. Corundum alumina has high mechanical strength. It resists wear and abrasion effectively. Handle them carefully to avoid chipping. Rough impacts can still cause breakage.

How long do these boats last?

Lifespan depends heavily on use conditions. Factors include maximum temperature reached, heating/cooling speed, and chemical exposure. With careful handling and avoiding thermal shock, they provide long service life. Replace them if you see cracks or significant surface wear.

(Corundum Alumina Ceramic Combustion Boat Unglazed)

REQUEST A QUOTE

RELATED PRODUCTS

High density industrial 99% alumina ceramic boat crucible

High Purity Alumina Ceramic Boat Pot High Temperature Fireclay Crucibles for Furnace at a Great Refractory Ceramic Plates

Refractory Ceramic 70 mm Alumina Ceramic Rectangular Crucible Boat

99% Purity High-Dense Alumina Ceramic Crucible Boat 99% Al2O3 Lab Testing Refractory Ceramic Plates Bending Processing Service

High Temperature Rectangle 99.6% Alumina Ceramic Boat Crucible with Lid for Laboratory