Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

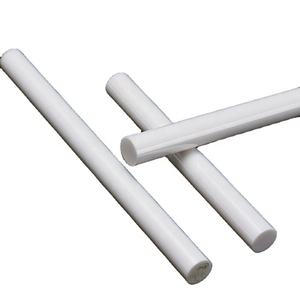

Overview of 99 Alumina Ceramic Plunger High Pressure Cleaning Machine Three Cylinder Plunger Ceramic Sleeve

99 Alumina Ceramic Plunger High Pressure Cleaning Machine Three Cylinder Plunger Ceramic Sleeve is engineered from 99%+ pure aluminum oxide (Al₂O₃), delivering unmatched durability and precision for demanding industrial applications. Designed to operate in extreme conditions, these plungers excel in high-wear, high-temperature, and corrosive environments, making them perfect for pumps, valves, fuel injection systems, and chemical processing equipment.

Features of 99 Alumina Ceramic Plunger High Pressure Cleaning Machine Three Cylinder Plunger Ceramic Sleeve

Superior Wear Resistance – Outlasts metal plungers in abrasive environments.

High-Temperature Stability – Maintains integrity up to 1600°C.

Corrosion & Chemical Resistance – Immune to acids, alkalis, and solvents.

Extreme Hardness (Hv 1500+) – Minimizes friction and extends service life.

Precision Machined – Tight tolerances for smooth, leak-free operation.

Customizable Designs – Available in various diameters, lengths, and surface finishes.

(99 Alumina Ceramic Plunger High Pressure Cleaning Machine Three Cylinder Plunger Ceramic Sleeve)

Specifications of 99 Alumina Ceramic Plunger High Pressure Cleaning Machine Three Cylinder Plunger Ceramic Sleeve

This alumina ceramic plunger is the core part inside high-pressure cleaning machines. It functions inside the pump cylinder. The plunger sustains extreme stress and friction constantly. The material is 99% pure alumina ceramic. This pureness provides it impressive residential or commercial properties. Alumina ceramic is incredibly tough. It rates simply listed below ruby on the solidity range. This solidity straight fights wear. It makes the bettor last much longer than steel parts. The ceramic surface area is very smooth. This level of smoothness minimizes friction dramatically. Less friction indicates less warm develops. Less warm means much less energy lost. Much less warmth also secures various other pump components.

The ceramic resists chemical assault quite possibly. Extreme cleaning chemicals won’t damage it. Water will not create corrosion or deterioration either. This resistance is essential for dependable operation. Temperature changes don’t impact it much. It stays secure whether warm or cold. This stability prevents fracturing under stress. The plunger fits exactly right into its ceramic sleeve. This pairing creates a limited, efficient seal. The seal protects against stress leakages inside the pump. Maintaining pressure is crucial for cleaning up power. Making use of ceramic bettors cuts maintenance requires dramatically. You replace them much less often than steel plungers. This saves substantial downtime and fixing prices. The pump runs smoother and quieter as well. Overall efficiency and machine life expectancy enhance. These bettors are necessary for demanding, continuous cleansing tasks. They manage the most difficult problems accurately.

(99 Alumina Ceramic Plunger High Pressure Cleaning Machine Three Cylinder Plunger Ceramic Sleeve)

Applications of 99 Alumina Ceramic Plunger High Pressure Cleaning Machine Three Cylinder Plunger Ceramic Sleeve

These alumina ceramic plungers update high-pressure cleaning devices. They’re constructed for challenging industrial work. Three cyndrical tubes collaborate to create effective water jets. Ceramic sleeves safeguard the bettors inside.

The secret is the 99% alumina ceramic material. This things is incredibly difficult. It stands up to wear far better than conventional metal components. Steel bettors wear down promptly under stress. Ceramic bettors last a lot longer. This means much less downtime for maintenance.

These bettors manage extreme pressure quickly. They won’t flaw or crack like softer materials. The smooth ceramic surface area minimizes rubbing inside the pump. Much less rubbing means the pump runs cooler and much more effectively. It also reduces power use with time.

Corrosion is a large trouble with water supply. Seawater or chemicals damage metal quickly. Alumina ceramic make fun of deterioration. It stays unaffected by the majority of rough fluids. This integrity is critical for aquatic cleaning or chemical plants.

Dust and little particles in water damages pumps. They scratch steel surfaces. The extreme solidity of ceramic shakes off this abrasion. Your pump stays cleaner inside. Efficiency remains strong for thousands of hours.

Exchanging used steel bettors costs cash and time. Ceramic bettors need changing much less usually. This saves significant operating costs. The initial investment repays promptly with decreased component adjustments.

These sleeves fit conventional three-cylinder high-pressure pumps. Installment is uncomplicated for professionals. They operate in washers for cars, buildings, ships, and factories. Any kind of area needing trustworthy, powerful water cleaning advantages.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 99 Alumina Ceramic Plunger High Pressure Cleaning Machine Three Cylinder Plunger Ceramic Sleeve

What makes these plungers last longer?

99% alumina ceramic is super hard. It handles high pressure easily. This material resists wear much better than metal. Your pump runs smoother for longer. You save money on replacements.

How do I care for the ceramic sleeves?

Keep water clean. Use filters to stop grit. Check seals often. Bad seals let dirt in. Dirt scratches ceramic fast. Lubricate regularly with clean water pump oil. Avoid harsh chemicals.

How do I know a sleeve is failing?

Watch your pressure gauge. Pressure drops mean trouble. Listen for strange pump noises. Look for leaks around the plunger. Any damage means replace it immediately. Don’t run a damaged pump.

Will these fit my existing pump?

Probably yes. These sleeves are standard size for many three-cylinder plunger pumps. Measure your old sleeve first. Check the inner diameter, outer diameter, and length. Match these numbers to our specs. Order the right size.

Where can I get genuine replacements?

Buy only from us or our authorized dealers. Many cheap copies exist. Fake ceramic cracks under pressure. Our parts use certified 99% alumina. We guarantee the material quality. Get the real part for safety.

(99 Alumina Ceramic Plunger High Pressure Cleaning Machine Three Cylinder Plunger Ceramic Sleeve)

REQUEST A QUOTE

RELATED PRODUCTS

0.005mm tolerance mirror polish alumina zirconia ceramic piston plunger

99% Al2O3 Alumina Ceramic Tube Aluminium Oxide Ceramic Plunger Pipe Roller for Industrial Application Parts

High Precision Alumina Ceramic Shaft Plunger and Al2O3 Sleeve Valve Assembled

99% Al2O3 Alumina Ceramic Piston Plunger for Pumps Valve Ceramic Tubes/parts

High Temperature Thermocouple Alumina Ceramic Tube for Plunger Protection