Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

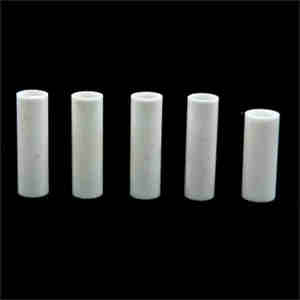

Overview of Customized Wear Resistant Alumina Ceramic Plunger for Pressure Pump Spare Parts Long Life

Customized Wear Resistant Alumina Ceramic Plunger for Pressure Pump Spare Parts Long Life is engineered from 99%+ pure aluminum oxide (Al₂O₃), delivering unmatched durability and precision for demanding industrial applications. Designed to operate in extreme conditions, these plungers excel in high-wear, high-temperature, and corrosive environments, making them perfect for pumps, valves, fuel injection systems, and chemical processing equipment.

Features of Customized Wear Resistant Alumina Ceramic Plunger for Pressure Pump Spare Parts Long Life

Superior Wear Resistance – Outlasts metal plungers in abrasive environments.

High-Temperature Stability – Maintains integrity up to 1600°C.

Corrosion & Chemical Resistance – Immune to acids, alkalis, and solvents.

Extreme Hardness (Hv 1500+) – Minimizes friction and extends service life.

Precision Machined – Tight tolerances for smooth, leak-free operation.

Customizable Designs – Available in various diameters, lengths, and surface finishes.

(Customized Wear Resistant Alumina Ceramic Plunger for Pressure Pump Spare Parts Long Life)

Specifications of Customized Wear Resistant Alumina Ceramic Plunger for Pressure Pump Spare Parts Long Life

These customized alumina ceramic bettors fit stress pumps perfectly. They are vital spare parts developed for tough jobs. Alumina ceramic is unbelievably difficult. This firmness battle wear effectively. Your pump components face abrasion continuously. Sand, slurry, and various other fragments trigger damage. Our bettors resist this damage much better than steel ones. Steel plungers wear down faster. They need changing frequently. That sets you back money and time.

We shape these plungers specifically to your pump version. Exact dimensions are essential. They guarantee a perfect seal inside the pump. Leaks cause stress loss and inefficiency. Our custom-made fit protects against leakages. You get regular, reputable pump pressure. This precision machining issues for performance.

The severe wear resistance is the key advantage. Alumina ceramic plungers manage abrasive fluids easily. They last a lot longer than conventional metal parts. Consider pump downtime. Frequent part adjustments stop manufacturing. Longer bettor life means much less downtime. You save on maintenance costs. You additionally minimize substitute part expenses. The plunger functions harder for longer.

These parts master demanding sectors. Mining procedures use them for slurry pumping. Power plants require them for fly ash handling. Chemical handling relies upon their chemical resistance. Alumina ceramic will not corrosion or corrode like steel. It manages severe chemicals well. This makes it excellent for harsh settings.

Update your pressure pump saves. Choose our personalized alumina ceramic bettors. They supply unrivaled sturdiness and worth. Anticipate considerably prolonged life span. Minimize your operational headaches.

(Customized Wear Resistant Alumina Ceramic Plunger for Pressure Pump Spare Parts Long Life)

Applications of Customized Wear Resistant Alumina Ceramic Plunger for Pressure Pump Spare Parts Long Life

Custom-made wear resistant alumina ceramic plungers solve big troubles in pressure pump systems. These components last a lot longer than steel alternatives. Alumina ceramic is extremely hard. It resists abrasion effectively. This material handles extreme problems conveniently. Pump systems deal with constant wear from abrasive slurries. Sand, minerals, and other bits rapidly damage ordinary steel bettors. Alumina ceramic plungers brush off this damages. They maintain pumps running smoothly for extended periods.

Pump downtime prices money and interrupts procedures. Regular plunger replacements imply stopping the pump. This causes lost production time. It likewise indicates added labor and component expenses. Our custom plungers drastically lower these closures. They last many times longer than typical plungers. You save substantially on upkeep and extra parts with time. Dependability enhances considerably.

These plungers work well across challenging industries. Mining slurry pumps relocate abrasive blends frequently. Ceramic plungers excel below. Oilfield shot pumps deal with comparable sandy obstacles. They profit greatly from this upgrade. Chemical processing pumps handle destructive fluids. Alumina ceramic stands up to chemical assault properly. Water jet cutting systems require high-pressure dependability. Ceramic plungers provide regular performance under stress.

We tailor each plunger exactly. We match your pump version and running specs precisely. Perfect fit and function are assured. This makes certain maximum performance and life expectancy. The ultra-smooth ceramic surface area lessens friction. Pump performance frequently boosts. Power savings include in the total price advantage. You get a more powerful pump system requiring less care.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Customized Wear Resistant Alumina Ceramic Plunger for Pressure Pump Spare Parts Long Life

What material makes these plungers last so long?

Alumina ceramic makes them. This material is super hard. It fights wear very well. It handles tough pumping jobs without breaking down fast. Ordinary metal plungers wear out quicker. Ours stay strong much longer.

How much longer do they last than metal ones?

They last many times longer. Exact life depends on your pump’s job. Things like pressure and what you’re pumping matter. We see them last 3 to 5 times longer than steel plungers often. This saves you money on replacements and downtime.

Can you make them fit my specific pump?

Yes. We make them specially for your pump model. Give us the pump brand and model number. We know dimensions are critical. We make the plunger match your pump parts perfectly. This ensures it works right and lasts long.

Is installing them difficult?

No. It’s straightforward. They fit just like your old metal plunger. You don’t need special tools or changes. Take out the worn plunger. Put the new ceramic one in its place. Follow your pump’s normal maintenance steps. It’s simple.

What maintenance do they need?

Very little. Their hardness means they resist wear exceptionally well. Keep the pump lubricated correctly. That’s the main thing. Check them during regular pump service. Look for cracks or chips. They usually last until the next planned service check.

(Customized Wear Resistant Alumina Ceramic Plunger for Pressure Pump Spare Parts Long Life)

REQUEST A QUOTE

RELATED PRODUCTS

High Precision 95 99 Ceramic Piston Pump Alumina Ceramic Piston Plunger Bushing Custom Processing Pressure Washer CNC Machining

High Pressure Pump Wear Resistance 99% Alumina Ceramic Rotary Plunger for

High-Temperature Resistant 95% Alumina Ceramic Piston Pump Plunger Bushing with Precision CNC Processing

Wearable Anti Erosion Alumina Ceramic Large bar Piston Plunger

Custom Alumina Ceramic Piston Pump & Plunger Bushing OEM CNC Machining Service for Industrial Pressure Washers