Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

Overview of Factory s 1050 1100 3003 5083 6061 6063 7075 Aluminum Alloy Bar Rod

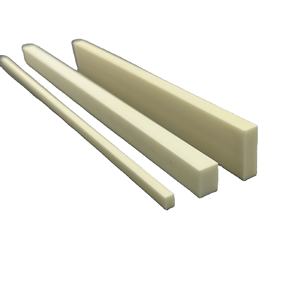

Alumina Bars are high-purity ceramic components made from aluminum oxide (Al₂O₃), offering exceptional hardness, thermal stability, and electrical insulation. Ideal for industrial, electronic, and high-temperature applications.

Features of Factory s 1050 1100 3003 5083 6061 6063 7075 Aluminum Alloy Bar Rod

High Thermal Resistance – Withstands extreme temperatures up to 1700°C.

Excellent Electrical Insulation – Low conductivity for high-voltage applications.

Superior Mechanical Strength – Resistant to wear, corrosion, and chemical erosion.

Precision Machinability – Can be customized to tight tolerances.

Wide Applications – Used in furnaces, semiconductors, medical devices, and more.

Specification of Factory s 1050 1100 3003 5083 6061 6063 7075 Aluminum Alloy Bar Rod

Manufacturing facility S makes aluminum alloy bars and rods. These products come in many dimensions. Diameters range from 10mm to 300mm. Sizes are typically 1000mm, 2000mm, or 3000mm. Custom lengths are feasible too. Shapes consist of round bars, square bars, and hex bars.

The factory uses a number of aluminum alloys. Alternatives are 1050, 1100, 3003, 5083, 6061, 6063, and 7075. Each alloy has various staminas. 1050 and 1100 are very pure light weight aluminum. They are soft and very easy to form. They withstand corrosion well. 3003 aluminum has actually manganese added. It is stronger than 1100. It likewise takes care of developing conveniently. 5083 aluminum contains magnesium. It uses superb resistance to seawater rust. It is strong as well. This makes it helpful for aquatic components.

6061 and 6063 alloys are really typical. They are heat-treatable. They attain high toughness with the T6 temper. 6061 is strong and equipments well. It welds quickly. 6063 is well-known for smooth surface areas. It is excellent for anodizing. It is frequently utilized for architectural trim. 7075 aluminum is the toughest option right here. It includes zinc. It is used where maximum toughness is critical. Think aerospace components or high-stress components. It is more challenging to develop than other alloys.

These bars and poles serve lots of sectors. Building uses them for structures and sustains. Automotive manufacturing facilities need them for components and installations. Machinery builders use them for shafts and rollers. Electronic devices rely upon them for heat sinks and housings. Marine applications benefit from the corrosion-resistant alloys. Even bicycle makers use them. The material is strong yet light. This saves weight. It saves power too. Factory S controls quality carefully. They check measurements precisely. They test mechanical residential or commercial properties. They guarantee the chemical composition is right. This assures trusted performance.

Applications of Factory s 1050 1100 3003 5083 6061 6063 7075 Aluminum Alloy Bar Rod

Manufacturing facility aluminum bars can be found in several grades. Each alloy offers different work. You need to choose the best one. 1050 and 1100 alloys are really pure light weight aluminum. They flex easily. They resist corrosion well. Individuals use them for indicators, nameplates, and ornamental trim. They additionally work for electrical parts due to the fact that they carry power well. Chemical storage tanks occasionally use them too.

3003 light weight aluminum is more powerful than 1050. It handles forming and welding conveniently. It prevails in storage tanks, warmth exchangers, and components needing good workability. You see it in kitchen tools and home builders’ hardware.

5083 light weight aluminum is famous for aquatic usage. It resists seawater rust extremely well. Watercraft builders use it for hulls and decks. Vehicle bodies and rail cars need its stamina and durability also. Stress vessels and offshore frameworks usually define 5083.

6061 and 6063 are the workhorses for structural jobs. 6061 is stronger. It’s used for hefty frames, platforms, and maker parts. 6063 is outstanding for squeezing out shapes. It has a smoother coating. It’s excellent for home window frameworks, door structures, pipelines, and furnishings tubes. Both weld well.

7075 is the toughest typical aluminum bar. It’s near steel stamina but much lighter. Aircraft components require this strength. High-stress equipments, shafts, and army parts utilize 7075. It’s more difficult to machine and weld than the others.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Factory s 1050 1100 3003 5083 6061 6063 7075 Aluminum Alloy Bar Rod

Factory Aluminum Alloy Bar Rods: 1050, 1100, 3003, 5083, 6061, 6063, 7075 – Common Questions

What are the main differences between these alloys?

Each alloy has unique properties. 1050 and 1100 are very pure aluminum. They are soft and easy to form. 3003 offers slightly better strength. 5083 is excellent for saltwater use. 6061 and 6063 are widely used general-purpose alloys. 6061 is stronger. 6063 is better for finishing. 7075 is the strongest option here. It is used in high-stress applications.

What sizes and shapes are available?

Factories supply these bars in round, square, and hexagonal shapes. Common diameters start small, like 6mm. Diameters go up to large sizes, over 150mm. Lengths are usually standard, like 3 meters or 6 meters. Custom sizes are possible. Ask the factory about specific dimensions.

What surface finishes can I get?

You typically get a mill finish. This is the standard surface from production. Other options exist. Polishing gives a smooth, shiny look. Anodizing adds color and extra corrosion protection. Brushing creates a uniform satin texture. Specify your finish requirement when ordering.

Which alloy is strongest?

7075 is the strongest aluminum bar here. It has high tensile strength. It is used in aerospace and high-performance parts. 6061 is also strong. It is a good, versatile choice. 5083 offers high strength in marine settings. 6063 is weaker but machines well. 1050, 1100, and 3003 are softer alloys. They are for less demanding jobs.

Which alloy handles corrosion best?

All aluminum alloys resist corrosion well. 5083 is exceptional in seawater. It is a top marine grade. 6061 and 6063 offer good general corrosion resistance. They are often anodized for more protection. 1050, 1100, and 3003 resist corrosion decently. 7075 is strong but needs protective coatings for harsh environments.

REQUEST A QUOTE

RELATED PRODUCTS

Factory s Customized 1050 1100 3003 5083 6061 6063 7075 Aluminum Alloy Bar Rod

High Purity 99% Alumina Al2o3 Ceramic Rod /ceramic Long Shaft/ bar with Threaded

Stock Solid 3-500mm 2017 2024 3003 3A21 5052 5083 6061 6063 T6 T4 Round Alloy Aluminum Rod Bar

High Precision Zirconia Ceramic Bar Rod for Industry

96% Al2O3 Ceramic Round Bar and Alumina Shaft