Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

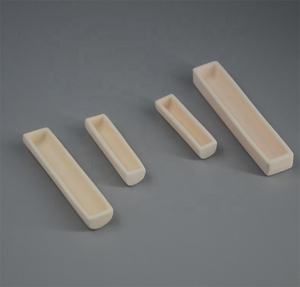

Overview of High Purity Alumina Zirconia Ceramic Tubes Crucibles Boats Zirconia Ceramic Structure Parts

High Purity Alumina Zirconia Ceramic Tubes Crucibles Boats Zirconia Ceramic Structure Parts is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of High Purity Alumina Zirconia Ceramic Tubes Crucibles Boats Zirconia Ceramic Structure Parts

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(High Purity Alumina Zirconia Ceramic Tubes Crucibles Boats Zirconia Ceramic Structure Parts)

Specifications of High Purity Alumina Zirconia Ceramic Tubes Crucibles Boats Zirconia Ceramic Structure Parts

Right here are the specifications for our high purity alumina zirconia ceramic tubes, crucibles, boats, and structural parts. These components supply outstanding efficiency for requiring applications. We use advanced ceramic products. This ensures superior buildings.

High purity alumina zirconia ceramic provides outstanding thermal security. It withstands severe temperature levels quickly. This product handles abrupt temperature modifications well. Thermal shock resistance is a crucial benefit. Your procedures gain from reputable heat handling. Thawing points exceed 1700 ° C regularly. These ceramics run reliably in harsh heater atmospheres.

Material purity is critical. Our porcelains preserve extremely high purity degrees. They contain marginal contaminations. This avoids contamination of sensitive products. These porcelains are optimal for semiconductor handling. They fit high-purity chain reaction perfectly. They function well in logical laboratories. Your examples stay unpolluted.

Mechanical strength is considerably improved. Zirconia strengthening makes the alumina matrix much stronger. These parts stand up to splitting and damaging efficiently. They provide premium wear resistance. Architectural parts preserve dimensional precision under load. This makes certain lengthy service life and dependability.

Chemical inertness is another major advantage. These porcelains resist attack from many acids and antacids. They are steady in harsh environments. Crucibles and boats withstand reactive melts without deterioration. Tubes provide secure flow for aggressive chemicals. Your tools lasts much longer.

Surface area surface options are offered. We can give components as-fired. We provide machined surface areas for accurate fits. Smooth surfaces reduce item adherence. This is important for crucibles and watercrafts. Architectural components achieve limited resistances for assembly. They fit properly right into your equipment.

These ceramic parts offer varied industries. They are crucial in metallurgy for melting precious metals. They are used in materials research study for crystal development. They function accurately in aerospace elements. They perform well in chemical processing tools. They support requiring commercial tasks.

(High Purity Alumina Zirconia Ceramic Tubes Crucibles Boats Zirconia Ceramic Structure Parts)

Applications of High Purity Alumina Zirconia Ceramic Tubes Crucibles Boats Zirconia Ceramic Structure Parts

High pureness alumina and zirconia ceramic components tackle tough commercial tasks. These products resist extreme warm unbelievably well. They don’t melt or damage down quickly. This makes them best for high-temperature furnaces. Crucibles and boats made from these ceramics hold liquified steels. They deal with reactive chemicals without contamination. Semiconductor producing counts heavily on this pureness. Tiny fragments destroy silicon chips. Alumina and zirconia tubes guide delicate procedures safely. They secure valuable materials inside activators.

Thermal shock is a big issue somewhere else. Lots of products fracture going from warm to cool quick. Zirconia stands out here. It takes care of unexpected temperature adjustments quite possibly. Crucibles used in fast home heating or cooling cycles require this. Alumina provides terrific firmness and wear resistance. Architectural parts like shafts, bearings, and liners advantage. They last a lot longer in unpleasant conditions. This saves downtime and replacement costs.

Chemical stability matters all over. Acids and antacid strike weaker products. High pureness alumina and zirconia withstand deterioration successfully. They work dependably in rough chemical atmospheres. Lab devices utilizes ceramic tubes and crucibles consequently. They keep experiments pure. Electrical insulation is one more essential function. These porcelains do not perform electrical energy. They safely isolate parts in high-voltage or high-power settings.

Zirconia parts are likewise very strong mechanically. They bear hefty loads without failing. Precision parts in equipment utilize this strength. The smooth surface area of these porcelains is important as well. Products don’t stick to them easily. Clean-up is simpler. Test loss is decreased. This matters in laboratories and manufacturing. Their stability in time ensures consistent outcomes. Processes remain foreseeable.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Purity Alumina Zirconia Ceramic Tubes Crucibles Boats Zirconia Ceramic Structure Parts

High Purity Alumina Zirconia Ceramic Tubes, Crucibles, Boats & Structure Parts: Key Questions Answered

What temperatures can these ceramic parts handle?

These parts handle extreme heat. Alumina-zirconia ceramics withstand temperatures up to 1650°C. This depends on the exact material mix. They are good for furnaces and high-heat processes.

Are they resistant to chemicals?

Yes. These ceramics resist many harsh chemicals. Acids, alkalis, and molten metals generally don’t damage them. This makes them reliable in labs and tough industrial settings. Check specific chemical compatibility for your use.

How long do alumina-zirconia ceramic parts last?

Lifespan varies. It depends on temperature, chemicals used, and mechanical stress. These parts are very hard and resist wear well. Proper handling prevents cracks and chips. They last much longer than metal parts in severe conditions.

Can I get custom shapes or sizes?

Yes. Manufacturers often offer custom shapes. Tubes, boats, crucibles, and complex structural parts can be made to your specifications. Provide detailed drawings or requirements. Production time might be longer for custom pieces.

What precautions are needed when handling these parts?

Handle them carefully. Avoid dropping or hitting them hard. Thermal shock is a risk. Don’t expose cold parts to sudden high heat. Let them heat up and cool down slowly. Inspect parts regularly for cracks or wear. Replace damaged parts quickly.

(High Purity Alumina Zirconia Ceramic Tubes Crucibles Boats Zirconia Ceramic Structure Parts)

REQUEST A QUOTE

RELATED PRODUCTS

Rectangle Alumina Ceramic Boats Crucible

Al2O3 Alumina Boat with Hole for Tube Furnace 100*24*17mm , Alumina Ceramic Boat Crucible

Al2O3 Alumina Ceramic Boat Crucible With Lid for Labs 60*30*15mm

Custom Alumina Ceramic Cylinder Part 99% Al2O3 Alumina Combustion Boat , Rectangle Alumina Ceramic Boats Crucible

High Temperature Rectangle Alumina Ceramic Boat