Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

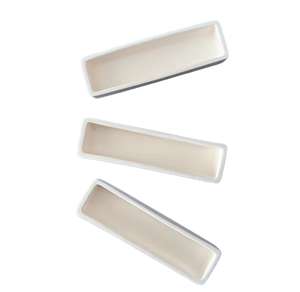

Overview of Refractory Alumina Ceramic Heat Resistant Boat Melting Pot Ceramic Crucible

Refractory Alumina Ceramic Heat Resistant Boat Melting Pot Ceramic Crucible is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of Refractory Alumina Ceramic Heat Resistant Boat Melting Pot Ceramic Crucible

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(Refractory Alumina Ceramic Heat Resistant Boat Melting Pot Ceramic Crucible)

Specifications of Refractory Alumina Ceramic Heat Resistant Boat Melting Pot Ceramic Crucible

This ceramic watercraft crucible handles high warmth jobs. It’s constructed for melting steels like gold and silver. You require trusted tools for these jobs. This product supplies that dependability. Alumina ceramic is the product here. It contains over 99% pure aluminum oxide. This purity matters. It suggests the crucible won’t add junk to your melts. Your final steel remains cleaner. You get purer results.

Heat resistance is critical. This crucible takes care of severe temperatures. It functions penalty approximately 1700 ° C (3092 ° F). That covers most rare-earth element melting. It holds up against quick heating also. Sudden temperature level modifications won’t split it easily. This toughness saves you cash. You replace crucibles much less typically. It carries out well over numerous heating cycles. Long life is a vital advantage.

The ceramic structure is dense. This offers it outstanding chemical resistance. Molten steels do not consume into it. Acids and bases trigger little damages. The smooth surface area assists. Molten product spurts cleanly. You obtain less sticking. Tidying up is easier. Its form is secure. It won’t warp under intense warm. Your melts stay contained securely. The boat design supplies a big surface. This advertises efficient warm transfer. Melting takes place quicker.

Resilience is outstanding. It withstands thermal shock well. Moving it from warm to cold won’t ruin it. Mechanical strength is high. It endures cautious handling. This crucible operates in labs. It operates in small factories. Jewelers discover it very valuable. Anybody needing a tough melting pot need to consider it. Efficiency corresponds. Reliability is shown.

(Refractory Alumina Ceramic Heat Resistant Boat Melting Pot Ceramic Crucible)

Applications of Refractory Alumina Ceramic Heat Resistant Boat Melting Pot Ceramic Crucible

These ceramic melting pots take care of extreme warmth. They’re made from premium alumina product. This special ceramic withstands temperatures far past regular metals. Manufacturing facilities and labs rely on them for melting metals, glass, and chemicals. Their toughness comes from high pureness alumina content, typically over 95%. This purity makes them incredibly difficult against heat shock. Unexpected temperature modifications won’t conveniently break them. That dependability is important for repeated melting tasks.

Jewelers use these crucibles daily for precious metals like gold and silver. The alumina doesn’t react with the molten metal. This maintains the melt pure and uncontaminated. Shops likewise depend on them for casting alloys. They hold up under extreme heating system problems. Their resistance to slag and change attack is essential. This means longer service life and fewer substitutes.

Chemical laboratories discover them crucial as well. Researchers melt specialty salts and compounds inside them. The ceramic won’t introduce unwanted components right into experiments. Even electronic devices manufacturing uses them. They refine products for semiconductors safely. Their thermal stability guarantees consistent results batch after batch. Steel refining plants make use of huge versions for continuous procedure. These pots sustain consistent direct exposure to thaw steel.

The smooth surface inside stops product sticking. This makes pouring less complicated and cleaning much faster. Their dense structure decreases disintegration. Molten material doesn’t seep into the ceramic. This maintains the pot’s honesty with time. They are necessary tools where high warm and product pureness matter.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Refractory Alumina Ceramic Heat Resistant Boat Melting Pot Ceramic Crucible

Here are 5 common questions about our Refractory Alumina Ceramic Crucible Melting Pots:

What is this crucible made from? It’s made from high-purity alumina ceramic. This material is very special. It handles extreme heat extremely well. Ordinary ceramics crack easily. This one is built tough for melting jobs.

How hot can it get? This crucible handles continuous temperatures up to 1800°C (3272°F). Short bursts can go even higher. It doesn’t melt. It doesn’t warp. It keeps its shape under intense heat. This makes it reliable for metal or glass work.

Why use ceramic instead of metal? Metal pots can react with your melt. They might add impurities. They can melt themselves. Alumina ceramic is different. It’s chemically inert. It won’t contaminate your gold, silver, or other materials. You get a cleaner result.

Is it safe for all materials? It works great for most metals like gold, silver, copper, and brass. It’s perfect for glass fusing too. But avoid strong alkalis or hydrofluoric acid. These can damage the ceramic surface over time. Check chemical compatibility first.

How do I care for it? Let it cool down completely after use. Don’t shock it with cold water. Clean it gently. Use a soft brush or cloth. Remove leftover material. Avoid harsh impacts. Handle it carefully. Store it somewhere dry and safe. This keeps it working well for a long time.

(Refractory Alumina Ceramic Heat Resistant Boat Melting Pot Ceramic Crucible)

REQUEST A QUOTE

RELATED PRODUCTS

Custom Rectangle Shape Alumina Ceramic Boat

Custom Alumina Crucible Boat Combustion Boat Machinable Ceramics

China High Alumina Al2o3 Ceramic Boat Crucible Refractory Aluminum Clay Ceramic Crucible With Cover For Metal Melting Furnace

High Temperature Alumina Ceramic Crucible Boat for Melting or Analyzing Metal

70ml 120*60*20mm Al2O3 Aluminum Oxide Rectangular Ceramic Boat Alumina Ceramic Sagger