Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

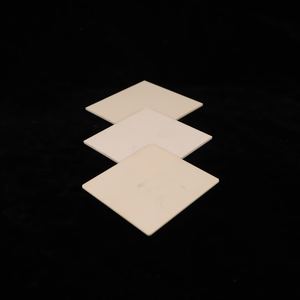

Overview of Customized DBC Direct Bonded Copper Both Sides Substrate 0.3mm Thickness Copper Plating Alumina Ceramic Plate

Customized DBC Direct Bonded Copper Both Sides Substrate 0.3mm Thickness Copper Plating Alumina Ceramic Plate is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of Customized DBC Direct Bonded Copper Both Sides Substrate 0.3mm Thickness Copper Plating Alumina Ceramic Plate

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(Customized DBC Direct Bonded Copper Both Sides Substrate 0.3mm Thickness Copper Plating Alumina Ceramic Plate)

Specification of Customized DBC Direct Bonded Copper Both Sides Substrate 0.3mm Thickness Copper Plating Alumina Ceramic Plate

This tailored DBC substrate starts with high-purity alumina ceramic. We bond thick copper layers straight onto both sides. The complete ceramic thickness is specifically 0.3 mm. This thin profile helps take care of warmth successfully.

You pick the copper thickness for every side. Alternatives vary from 0.1 mm to 0.6 mm. The copper layer matches your circuit pattern specifically. We etch the copper based upon your design files. This produces accurate electrical paths.

Alumina ceramic offers exceptional insulation. It withstands high voltages accurately. The material takes care of severe temperature levels well. It doesn’t break under thermal biking stress. This ensures long-term efficiency security.

The direct bonding process creates a solid web link. Copper adheres snugly to the ceramic. There is no adhesive or filler material. This bond makes it through duplicated heating & cooling. It stops delamination problems.

This substratum relocates warm away quickly. Copper carries out heat superbly. The straight bond decreases thermal resistance. Hot spots dissipate rapidly. Elements remain cooler and last longer.

Electric performance is additionally first-class. Copper carries high currents conveniently. The etched patterns minimize resistance losses. Signal courses stay tidy and efficient. This is vital for power density.

We make these plates to your specific demands. Specify the total measurements. Choose the copper density for top and bottom. Offer your circuit pattern style. We deal with complicated forms and great features.

Regular usages include power components. IGBTs and MOSFETs often remain on these plates. Electric automobile power systems rely upon them. Solar inverters and industrial motor drives use them too. Any kind of high-power electronics benefit.

The 0.3 mm ceramic core is key. It balances good electrical isolation with effective thermal transfer. Thinner ceramic improves heat spreading. It keeps the whole setting up compact.

(Customized DBC Direct Bonded Copper Both Sides Substrate 0.3mm Thickness Copper Plating Alumina Ceramic Plate)

Applications of Customized DBC Direct Bonded Copper Both Sides Substrate 0.3mm Thickness Copper Plating Alumina Ceramic Plate

Custom-made DBC substratums with 0.3 mm copper plating on both sides of an alumina ceramic plate fix hard troubles in high-power electronic devices. These components handle significant heat and electrical tons. The thin copper layer permits exact circuit patterns. The alumina base is tough and insulates electrical power well. This combination is vital where dependability issues.

Power semiconductor modules use this substratum heavily. Assume electric lorry electric motor controllers and commercial motor drives. The direct copper bonded layer actions warmth away from power chips quick. This protects against overheating and failing. The 0.3 mm copper density provides an excellent course for power. It additionally offers a solid base for installing chips and parts.

High-voltage power supplies additionally depend on this modern technology. The alumina ceramic withstands high voltages safely. The adhered copper layers develop secure, low-resistance links. This is vital for converters and inverters in solar power systems or wind turbines. Reliable warmth transfer maintains these systems running longer without issues.

Automotive electronics, especially in EVs and crossbreeds, require this substratum. Power modules handle battery charging and motor control. These produce intense heat. The DBC substratum draws that heat into cooling systems promptly. Its compact dimension fits tight areas in vehicles. The 0.3 mm copper plating assists take care of high currents properly.

Industrial applications require longevity. Electric motor drives, welding equipment, and UPS systems see rough problems. The alumina ceramic handles thermal shock and resonance. The solid copper bond makes sure connections remain intact. This substrate supports high power thickness layouts. It makes gadgets smaller and more powerful.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Customized DBC Direct Bonded Copper Both Sides Substrate 0.3mm Thickness Copper Plating Alumina Ceramic Plate

What is a Customized DBC Substrate?

It’s a special circuit board. We bond copper directly onto both sides of an alumina ceramic plate. This creates strong electrical paths. The process ensures excellent heat spreading too. We customize the copper pattern for your exact circuit needs. This is different from standard circuit boards.

Why choose DBC with 0.3mm copper plating?

The 0.3mm copper thickness offers a good balance. It provides strong current carrying ability. It handles high power loads well. This thickness also allows for precise etching of complex circuit patterns. It’s reliable for demanding electronics needing good heat management.

Is the 0.3mm thickness the only option?

No, it’s not. The 0.3mm copper plating is a common standard thickness we offer. We can provide other thicknesses too. You tell us your power requirements and design. We recommend the best copper thickness for your specific project. Customization includes this.

What parts can be customized?

We customize many features. The copper pattern shape and size are key. We adjust the overall dimensions of the ceramic plate to fit your device. We can add special holes or cutouts. We precisely control the copper thickness. The alumina ceramic base properties might also be adjusted slightly. We build it to your exact specifications.

How well does it handle heat?

Very well. Alumina ceramic is naturally good at insulating electricity. It also moves heat efficiently. The direct bonded copper on both sides spreads heat fast. This combination prevents overheating spots. Your electronic components stay cooler. This improves performance and lifespan, especially for power modules and LEDs.

(Customized DBC Direct Bonded Copper Both Sides Substrate 0.3mm Thickness Copper Plating Alumina Ceramic Plate)

REQUEST A QUOTE

RELATED PRODUCTS

High Mechanical Strength Metallized Alumina Ceramic Plate AlN Substrate for DPC Dbc Dcb

High Strength Alumina Foam Ceramics Porous Ceramic Foam Filter Plate Ceramic Filter

Alumina Disc Heater Ceramic Heating Plate with 5V 12V 24V

220V MCH Alumina Ceramic Plate Heater

Factory Supply Customized Insulated Alumina Plate Alumina Ceramic Plate for Heat Dissipation