Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

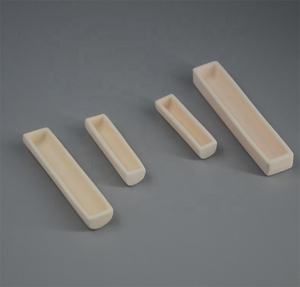

Overview of High Purity High Temperature square 99 Alumina Ceramic Boat for Thermal Analysis

High Purity High Temperature square 99 Alumina Ceramic Boat for Thermal Analysis is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of High Purity High Temperature square 99 Alumina Ceramic Boat for Thermal Analysis

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(High Purity High Temperature square 99 Alumina Ceramic Boat for Thermal Analysis)

Specifications of High Purity High Temperature square 99 Alumina Ceramic Boat for Thermal Analysis

This ceramic watercraft takes care of high warm in thermal evaluation. It’s made of 99% alumina. This purity issues. It stops contamination of your examples. You obtain clean outcomes. The square form holds samples firmly. It fits typical heater areas well. Heat usage is its stamina. It withstands 1700 ° C quickly. Brief ruptureds to 1800 ° C are feasible. This suits demanding tests like TGA or DSC. Thermal shock resistance is great. The watercraft heats up and cools without splitting. Its reduced thermal expansion assists security. The surface area is smooth. This stays clear of example responses. Dimensions are exact. Typical dimensions exist. Customized dimensions are offered also. Chemical resistance is superb. Acids and bases do not damage it. Mechanical stamina is high. It stands up to damage during handling. Lengthy life span minimizes costs. You use it consistently. Consistent efficiency is essential. It makes certain trustworthy information. The watercraft works well in inert or oxidizing environments. Applications consist of materials study. Semiconductor processing uses it. Quality control labs require it. It sustains powders, granules, little parts. Easy managing conserves time. Cleaning is simple. This watercraft is a reliable device. It provides accuracy under extreme warmth.

(High Purity High Temperature square 99 Alumina Ceramic Boat for Thermal Analysis)

Applications of High Purity High Temperature square 99 Alumina Ceramic Boat for Thermal Analysis

High pureness high temperature square 99 alumina ceramic watercrafts are vital devices in thermal analysis laboratories. They hold samples securely during demanding heat treatments. Their high pureness degree (99% alumina) is essential. It avoids sample contamination during delicate experiments. Pollutants from the boat material could mess up examination results. The square form provides practical advantages. It takes full advantage of useful area inside heating systems and evaluation tools. This allows even more examples per run or far better positioning. Designers value this reliable style.

These boats hold up against severe temperatures conveniently. They manage continual direct exposure over 1700 ° C without deteriorating. This thermal stability is non-negotiable for dependable analysis. Abrupt temperature level adjustments won’t fracture them. They show exceptional thermal shock resistance. This toughness guarantees regular performance run after run. Labs depend on this dependability.

Chemical inertness is an additional significant benefit. The alumina product stands up to assault from a lot of acids, bases, and responsive compounds. This secures both the example and the watercraft itself during severe screening. You get tidy data without undesirable responses. The product is also really dense. This prevents gas infiltration and maintains the sample atmosphere steady. Specific measurements need this security.

These ceramic boats are important for specific thermal procedures. Thermogravimetric evaluation (TGA) utilizes them to gauge weight adjustments under heat. Differential scanning calorimetry (DSC) relies upon them to examine heat flow reactions. They are crucial for calcination procedures. They are vital for sintering products research. Semiconductor manufacturing requires them for diffusion actions. Chemical vapor deposition (CVD) processes use them as example holders. They supply a steady, inert platform under intense heat and reactive gases.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Purity High Temperature square 99 Alumina Ceramic Boat for Thermal Analysis

People often ask about our high purity square alumina boats. Here are the top five questions we get:

What’s special about these ceramic boats? They are made from 99% alumina. This material is very strong. It handles extreme heat well. It also resists chemical attack. This makes them perfect for demanding thermal analysis like TGA or DSC. They keep your samples safe and stable.

How hot can I use these boats safely? You can use them continuously up to 1600°C (2912°F). They handle short bursts even hotter, maybe 1700°C (3092°F). Always check your furnace specs first. Match the boat to your furnace’s max temperature.

Why is high purity so important? Impurities cause problems. They can react with your sample. They might release gases at high heat. This messes up your thermal analysis results. Our 99% alumina purity minimizes these risks. You get cleaner, more accurate data.

How do I clean them after use? Cleaning is simple. Heat the boat in air to about 1000°C (1832°F). This burns off most organic residues. For tougher contamination, soak the boat in strong acid. Use nitric acid or hydrochloric acid. Then rinse it very well with pure water. Dry it completely before reuse.

Why are they square shaped? The square shape fits better in many furnaces. It provides more usable surface area compared to round boats. This shape helps position samples consistently. Consistent positioning improves test repeatability. It also makes loading powders easier.

(High Purity High Temperature square 99 Alumina Ceramic Boat for Thermal Analysis)

REQUEST A QUOTE

RELATED PRODUCTS

China High Alumina Al2o3 Ceramic Boat Crucible Refractory Aluminum Clay Ceramic Crucible With Cover For Metal Melting Furnace

99% Al2O3 Alumina Combustion Boat , Rectangle Alumina Ceramic Boats Crucible

Alumina Al2o3 Ceramic Crucible/boat Container Ceramic Products

Corundum Alumina Ceramic Combustion Boat Unglazed

Large Diameter 5000ml Alumina Ceramic Boat Crucible Cylinder Crucible with Factory