Professional Premium Aluminum Oxide Products Supplier

1. Alumina Ceramic Plates: The Chemical Framework

1.1 What Are Alumina Ceramic Plates?

Alumina ceramic plates, composed mostly of aluminum oxide (Al ₂ O₂), are a cornerstone of modern materials science. These plates are engineered through sophisticated sintering strategies to achieve outstanding pureness and structural stability. The term “alumina” describes the crystalline type of lightweight aluminum oxide, which comprises over 90% of the product in the majority of industrial applications. Their manufacturing includes specific control of basic material composition, particle size, and shooting conditions, guaranteeing an equilibrium of mechanical strength and useful efficiency.

1.2 The Chemical Framework of Alumina Ceramic Plates

The chemical structure of alumina ceramic plates is rooted in their corundum-based lattice, a hexagonal close-packed plan of oxygen ions with aluminum ions inhabiting₂-thirds of the octahedral sites. This atomic arrangement grants the material its amazing firmness and thermal stability. The high bond energy between Al³ ⁺ and O² ⁻ ions additionally contributes to its resistance to chemical deterioration, making it excellent for hostile settings. Additionally, the product’s reduced porosity– accomplished via high-pressure sintering– improves its mechanical properties, such as compressive strength and crack resistance.

2. Core Properties of Alumina ceramic Plates

2.1 Physical and Chemical Characteristics

Alumina ceramic plates show a distinct mix of physical and chemical properties that set them apart in commercial applications. Trick qualities include:

High Hardness: With a Mohs hardness of 9 (second only to ruby and silicon carbide), these plates stand up to abrasion and wear, even under extreme problems.

Thermal Security: With the ability to endure temperatures of approximately 1600 ° C, they remain dimensionally secure in high-heat environments.

Chemical Inertness: Resistant to acids, alkalis, and molten steels (other than hydrofluoric acid and warm concentrated antacids), they prosper in destructive settings.

Electric Insulation: Exceptional dielectric toughness (10– 25 kV/mm) and low dielectric continuous (ε ≈ 9– 10) make them indispensable in electronic devices.

2.2 Practical Advantages

Beyond their intrinsic properties, alumina ceramic plates offer functional convenience. For instance, their reduced thermal development coefficient (7.2 × 10 ⁻⁶/ ° C )ensures marginal dimensional changes during thermal cycling, lowering stress and anxiety on integrated elements. In addition, their biocompatibility– specifically in 99.5% pureness qualities– enables applications in clinical implants and surgical tools. The capability to tailor homes via doping or surface alteration better broadens their utility, such as enhancing thermal conductivity for heat dissipation in power electronics.

| Specification | Details |

| Material Composition | Primarily composed of Al₂O₃ (Oxide of Aluminum) with high purity (typically >99%) |

| Hardness | High hardness, typically around 9 on the Mohs scale |

| Density | Approximately 3.95-4.02 g/cm³ |

| Flexural Strength | 350-500 MPa (depending on grade and processing) |

| Compressive Strength | 2000-3000 MPa |

| Fracture Toughness | 3.5-5.0 MPa·m½ |

| Thermal Conductivity | 20-30 W/m·K (varies with purity and microstructure) |

| Thermal Expansion Coefficient | 7-8 x 10⁻⁶/°C |

| Dielectric Strength | 15-20 kV/mm (at room temperature) |

| Dielectric Constant | 8.4-10 (at 1 MHz) |

| Loss Tangent | < 0.001 (at 1 MHz) |

| Chemical Resistance | Excellent resistance to acids, alkalis, and salts; chemically inert in most environments |

| Operating Temperature Range | -270°C to +1700°C (depending on specific application and grade) |

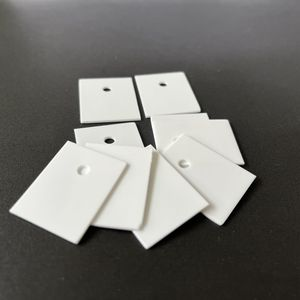

| Surface Finish | Available in various finishes such as polished, ground, or as-fired (natural surface) |

| Tolerance | ±0.1 mm (standard tolerance; tighter tolerances available with precision machining) |

| Thickness | 0.5 mm to 20 mm (custom thicknesses available upon request) |

| Size | Standard sizes up to 300 mm x 300 mm; larger sizes available through custom manufacturing |

| Color | Typically white or off-white; other colors possible with specific additives |

| Applications | Widely used in electronics (as substrates and insulators), mechanical components (bearings, seals), chemical processing (corrosion-resistant parts), aerospace, and more |

3. Strengths and Limitations of Alumina Ceramic Plates

3.1 Benefits of Alumina ceramic Plates

The staminas of alumina ceramic plates are exceptional in numerous markets. Their superior wear resistance extends device lifespans, minimizing maintenance expenses in industries such as mining and metallurgy. The lightweight nature (density 3.8– 4.0 g/cm₂ )compared to steels like steel (7.8 g/cm FIVE) additionally decreases power intake in equipment. Environmentally, their safe structure lines up with RoHS conformity, making them a sustainable choice. In addition, their layout flexibility allows for intricate geometries, meeting the demands of accuracy engineering.

3.2 Disadvantages of Alumina Ceramic Plates

However, no product lacks drawbacks. Alumina ceramic plates deal with low fracture durability (K_IC ≈ 4.8 MPa · m 1ST/₂ ), making them prone to fracturing under the influence of or shock tons. This brittleness limits their usage in vibrant mechanical systems. Furthermore, making complexity– such as the demand for high-temperature sintering and ruby tooling for machining– elevates production costs. While their thermal conductivity (30 W/m · K )suffices for many applications, it lags behind materials like silicon nitride or aluminum nitride in high-power scenarios.

4. Analysis of the 5 Major Industrial Application Circumstances

4.1 Electronics and Semiconductor Production

In the electronic devices field, alumina ceramic plates are the unhonored heroes of circuit reliability. Their high insulation resistance (> 10 ¹⁴ Ω · cm) and low signal loss (ε ≈ 9– 10) make them ideal for substrates in crossbreed incorporated circuits (HICs) and power components. For example, 96% alumina plates are extensively used in DBC (Direct Bonded Copper) innovation for LED cooling and IGBT (Shielded Entrance Bipolar Transistor) product packaging. Their capability to dissipate warmth efficiently while keeping electrical isolation ensures the durability of high-frequency and high-power devices.

4.2 Aerospace and Defense

The aerospace market relies upon alumina ceramic plates for extreme sturdiness. Elements like generator blades, burning chamber cellular linings, and sensor real estates take advantage of the product’s thermal shock resistance and chemical inertness. In hypersonic cars, alumina ceramics hold up against temperature levels going beyond 1000 ° C while standing up to oxidation, a vital factor in engine longevity. Additionally, their lightweight yet robust nature contributes to fuel effectiveness and architectural honesty in spacecraft and military airplanes.

4.3 Automotive and Energy Systems

In electrical lorries (EVs) and renewable energy systems, alumina ceramic plates play a pivotal role in thermal management. For example, in battery monitoring systems (BMS), they serve as dielectric separators in between high-voltage elements, stopping short circuits while enabling reliable heat transfer. Similarly, in solar inverters and wind generator generators, their rust resistance ensures functional stability in damp or brackish atmospheres. The material’s compatibility with high-temperature adhesives additionally streamlines setting up procedures in auto production.

4.4 Medical and Biotechnology

The biocompatibility of high-purity alumina plates has transformed clinical device design. Applications vary from oral implants and hip prostheses to lab devices for DNA sequencing. For instance, 99.5% alumina plates are use in bone graft scaffolds, where their inertness avoids immune rejection. In diagnostic tools, their smooth, impermeable surface areas stand up to bacterial emigration, ensuring sterility in crucial treatments.

4.5 Industrial Equipment and Wear-Resistant Components

Alumina ceramic plates are the workhorses of hefty sectors. In mining and cement production, they function as wear-resistant cellular linings in grinding mills and conveyor systems, decreasing downtime by 50- 70%. Their reduced rubbing coefficient (0.1– 0.2) additionally improves performance in hydraulic shutoffs and pump seals. In the fabric sector, alumina nozzles and guides ensure precision in fiber spinning, reducing product waste.

5. Technical Supremacy of Zirconium Dioxide Ceramics

While alumina ceramics dominate several applications, zirconium dioxide (ZrO2) ceramics offer corresponding benefits. Notably, ZrO ₂ exhibits exceptional crack sturdiness (K_IC ≈ 10 MPa · m 1ST/₂) due to its phase improvement strengthening device, making it suitable for impact-prone environments like reducing tools and biomedical implants. Its premium insulation properties and biocompatibility further enhance its charm in innovative clinical gadgets. Nonetheless, ZrO ₂’s limited thermal stability (degrades over 500 ° C) and greater expense compared to alumina placement make it a specialized option instead of a universal remedy.

6.Final thought

Alumina ceramic plates stand as a testament to the resourcefulness of materials design, bridging the gap between theoretical performance and real-world application. From pioneering technologies in electronic devices to uncompromising durability in aerospace, their value is obvious. While challenges like brittleness continue, ongoing developments in composite materials and surface area therapies promise to intensify their potential. For sectors seeking trusted, high-performance services, alumina ceramic plates remain a vital property in the quest for technological quality.

Supplier

RBOSCHCO is a trusted global Alumina Ceramic Plates supplier & manufacturer with over 12 years experience in providing super high-quality chemicals and Nanomaterials. The company export to many countries, such as USA, Canada, Europe, UAE, South Africa,Tanzania,Kenya,Egypt,Nigeria,Cameroon,Uganda,Turkey,Mexico,Azerbaijan,Belgium,Cyprus,Czech Republic, Brazil, Chile, Argentina, Dubai, Japan, Korea, Vietnam, Thailand, Malaysia, Indonesia, Australia,Germany, France, Italy, Portugal etc. As a leading nanotechnology development manufacturer, RBOSCHCO dominates the market. Our professional work team provides perfect solutions to help improve the efficiency of various industries, create value, and easily cope with various challenges. If you are looking for Alumina Ceramic Plates, please send an email to: sales1@rboschco.com

Tags: alumina plate,alumina ceramic plates,aluminum oxide ceramic plate