Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

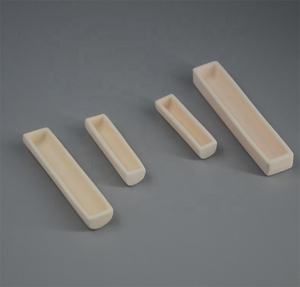

Overview of High Temperature Pure Zirconia Crucible, Alumina Rectangular Boat Ceramic Crucible

High Temperature Pure Zirconia Crucible, Alumina Rectangular Boat Ceramic Crucible is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of High Temperature Pure Zirconia Crucible, Alumina Rectangular Boat Ceramic Crucible

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(High Temperature Pure Zirconia Crucible, Alumina Rectangular Boat Ceramic Crucible)

Specifications of High Temperature Pure Zirconia Crucible, Alumina Rectangular Boat Ceramic Crucible

Pure zirconia crucibles deal with severe heat. They stand up to temperature levels over 2000 ° C. This makes them ideal for very hot tasks. Zirconia is extremely pure. This pureness protects against contamination. Your materials remain tidy. The crucibles are strong. They withstand damaging under tension. They also deal with unexpected temperature level adjustments well. This is thermal shock resistance. You get reliable efficiency. Zirconia crucibles operate in air or inert gases. Select them for requiring applications like melting rare-earth elements or advanced ceramics. They are available in usual laboratory dimensions. Requirement volumes are 5ml, 10ml, 15ml, 20ml, 25ml, 30ml, 50ml, 100ml. Larger dimensions exist as well. Inspect the exact measurements you require.

Alumina rectangular boat crucibles are different. They are shaped like lengthy trays. This shape serves for many tasks. You can hold examples flat. They are good for sintering or calcining powders. Alumina handles high heat too. Its optimum temperature is about 1750 ° C. This is still really high. Alumina is tough and durable. It stands up to chemical attack from several substances. The rectangle-shaped boats are steady. They will not tip easily. This is necessary throughout heating. Alumina also uses great thermal shock resistance. It cools off securely. These boats come in numerous basic sizes. Typical sizes are 50mm, 60mm, 70mm, 80mm, 90mm, 100mm, 120mm. Sizes are smaller sized. Typical widths are 10mm, 15mm, 20mm, 25mm, 30mm. Heights are usually low. Standard heights are 5mm, 8mm, 10mm, 15mm. You need the best dimension for your furnace and examples.

(High Temperature Pure Zirconia Crucible, Alumina Rectangular Boat Ceramic Crucible)

Applications of High Temperature Pure Zirconia Crucible, Alumina Rectangular Boat Ceramic Crucible

Heat pure zirconia crucibles handle extreme heat. They withstand temperature levels near 2000 ° C. This makes them essential for demanding work. Melting responsive metals like titanium or zirconium needs zirconia. Zirconia stands up to strike from these steels. Expanding unique crystals requires zirconia crucibles. They provide a stable, tidy setting. Zirconia remains strong at extremely high temperatures. It does not quickly crack under thermal stress. This integrity is crucial for pricey processes.

Alumina rectangle-shaped watercraft crucibles are common research laboratory devices. They work well up to 1700 ° C. Their shape is sensible. Alumina boats lug examples conveniently. They glide efficiently right into tube heaters. Warm dealing with products happens inside these boats. Assessing powders makes use of alumina crucibles. Sintering tiny parts depends on them. Alumina provides excellent chemical resistance. It deals with several acids and bases. This flexibility is important.

Both zirconia and alumina crucibles share essential benefits. They withstand thermal shock. Abrupt temperature level changes hardly ever damage them. Their chemical inertness protects samples. Reactions with the crucible product are minimized. This purity guarantees exact outcomes. These ceramics last a long period of time. They stand up to duplicated home heating cycles. This durability lowers substitute expenses. Customers save cash with time. Dealing with high temperatures is their core function. They do dependably under hard conditions. Industries like aerospace, metallurgy, and research rely on these tools. Quality control laboratories utilize them daily. Production processes incorporate them. These crucibles hold their form. They shield beneficial products. The investment pays off via constant performance.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Temperature Pure Zirconia Crucible, Alumina Rectangular Boat Ceramic Crucible

High Temperature Zirconia Crucible & Alumina Rectangular Boat: Key Questions

What makes zirconia crucibles handle extreme heat?

Zirconia crucibles use zirconium dioxide. This material has a very high melting point. It stays solid and stable much longer than many other ceramics under intense heat. This stability is crucial for melting very high-temperature metals or compounds.

Why might an alumina boat crack with sudden temperature changes?

Alumina ceramic is strong. It resists wear well. But its structure doesn’t expand or contract as easily as zirconia when heated or cooled fast. Quick temperature shifts create internal stress inside the alumina. This stress can cause cracks or breaks.

Which ceramic resists harsh chemicals better?

Alumina generally offers superior chemical resistance. It withstands attack from strong acids, alkalis, and reactive molten salts better than zirconia in many situations. This makes alumina boats good for chemical processing tasks. Zirconia can be vulnerable to certain acidic environments.

Why choose a rectangular alumina boat over a round crucible?

Shape matters for the job. Rectangular alumina boats provide a long, flat surface. This is ideal for evenly heating samples like wafers, plates, or powder beds during processes like sintering or annealing. Round zirconia crucibles are better for containing and melting larger volumes of material.

How should I clean these ceramics after use?

Cleaning needs care. Avoid harsh impacts. Let the ceramic cool completely first. Use warm water and a soft brush for loose residue. For tougher buildup, soaking in mild acid or solvent might help. Check chemical compatibility first. Never use abrasive cleaners. Thermal shock during cleaning can damage them.

(High Temperature Pure Zirconia Crucible, Alumina Rectangular Boat Ceramic Crucible)

REQUEST A QUOTE

RELATED PRODUCTS

Alumina Al2o3 Ceramic Crucible/boat Container Refractory Alumina Ceramic Furnace

High Temperature Resistant Alumina Porcelain Ceramic Cupel Boat

Customized Alumina Molten Metal Crucible Laboratory 95 Al2O3 Ceramic Boat

High Purity High Temperature square 99 Alumina Ceramic Boat for Thermal Analysis

Al2O3 Alumina Combustion Boat with Lid , Rectangle Alumina Ceramic Boats Crucible