Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

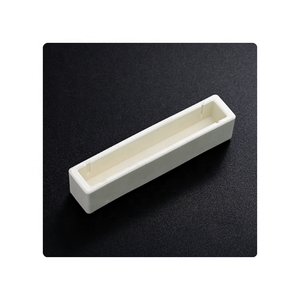

Overview of High density industrial 99% alumina ceramic boat crucible

High density industrial 99% alumina ceramic boat crucible is precision-engineered vessels made from 99%+ pure aluminum oxide (Al₂O₃). Designed for high-temperature and corrosive environments, they are widely used in semiconductor processing, heat treatment, CVD/PVD applications, and laboratory experiments. Their superior thermal and chemical stability ensures reliable performance under extreme conditions.

Key Features of High density industrial 99% alumina ceramic boat crucible

Extreme Temperature Resistance – Stable up to 1800°C with low thermal expansion.

Superior Chemical Resistance – Resists acids, alkalis, and aggressive gases.

High Mechanical Strength – Durable and resistant to thermal shock.

Precision Design – Smooth surfaces & uniform dimensions for consistent processing.

Customizable Shapes & Sizes – Available in standard and tailored configurations.

(High density industrial 99% alumina ceramic boat crucible)

Specifications of High density industrial 99% alumina ceramic boat crucible

This alumina ceramic boat crucible is built hard for requiring industrial jobs. It makes use of high-purity 99% alumina ceramic. This material is packed tight for high thickness. High thickness means the crucible resists use far better. It deals with heavy usage over a long period of time. The shape is a flat boat design. This design holds components or materials safely throughout handling.

It manages extreme warm extremely well. You can utilize it continually at temperatures up to 1650 ° C. Short bursts of heat up to 1750 ° C are additionally possible. The crucible copes with fast temperature changes. It will not fracture conveniently when warming up or cooling off rapidly. This thermal shock resistance is critical for many heating system cycles.

Chemicals don’t bother this crucible much. It takes on strong acids and alkalis. Molten steels and salts will not damage it easily either. This chemical inertness keeps your materials pure. It prevents contamination during high-temperature actions. The surface remains smooth and non-reactive.

The crucible is physically solid. It has high mechanical toughness. This strength withstands damaging under load or influence. It will not bend or warp under its own weight at high warm. Dimensional security is excellent. The crucible maintains its exact form cycle after cycle. This makes certain regular handling results.

Its electric insulation residential or commercial properties are top-notch. The material doesn’t perform electrical energy. This is essential for several digital component processes. The smooth surface area finish is easy to clean. Deposit does not stick well. This simplifies maintenance in between batches. Manufacturing high quality corresponds. Exact forming and shooting warranty trustworthy efficiency.

(High density industrial 99% alumina ceramic boat crucible)

Applications of High density industrial 99% alumina ceramic boat crucible

High thickness commercial 99% alumina ceramic boat crucibles are essential devices. They are built challenging for demanding industrial settings. The high pureness alumina material provides exceptional efficiency. It stands up to extreme heat extremely well. This makes them ideal for high temperature furnace procedures. They manage sudden temperature modifications effectively. This thermal shock resistance is crucial.

These crucibles are chemically inert. They will not respond with the majority of chemicals. This security is important in aggressive environments. The product is very hard and sturdy. It stands up to wear and abrasion in time. This implies the boats last much longer under heavy usage. They preserve their shape and honesty. This integrity is essential for constant manufacturing outcomes.

A major application is semiconductor manufacturing. These ceramic boats lug silicon wafers through essential steps. They withstand high heat throughout diffusion and oxidation. They likewise deal with chemical vapor deposition procedures. The product purity avoids contamination of sensitive wafers. This is non-negotiable for chip top quality.

Solar battery manufacturing relies on these crucibles as well. They transport photovoltaic wafers in high temperature heaters. The inert alumina makes sure no undesirable reactions occur. This protects the efficiency of the solar batteries. The watercrafts have to do reliably set after set.

These crucibles are additionally utilized in various laboratory setups. They support heat experiments and material screening. The metallurgy sector utilizes them for steel evaluation and warmth therapies. They are located in kilns for firing advanced porcelains. Any type of process requiring a steady, heat carrier benefits. Their design firmly holds examples or components during processing. This prevents movement or damages inside the heater. The smooth surface allows easy cleansing between usages. This reduces cross-contamination threats.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High density industrial 99% alumina ceramic boat crucible

What’s the highest temperature this crucible handles?

It handles extremely high heat. The crucible works fine up to 1650°C (3000°F). This suits most high-temperature industrial processes. It won’t melt or weaken at these temperatures.

Can it handle sudden temperature changes?

Yes, it resists thermal shock very well. You can heat it fast or cool it down quickly. The material’s strength prevents cracking. This toughness is important for demanding production cycles.

Will chemicals damage the crucible?

It fights off most chemicals. Acids and alkalis won’t easily harm it. Strong bases might cause slight wear over a long time. Overall, it offers excellent chemical durability.

How long will one crucible last?

Its lifespan depends heavily on use. Frequent high temperatures and harsh chemicals wear it down faster. Handled carefully, it lasts much longer than cheaper crucibles. Its toughness provides good value.

How do I clean it after use?

Cleaning is usually simple. Use water or mild solvents. Stubborn residues might need special cleaning methods. Avoid harsh mechanical scrubbing. It generally cleans up easily.

(High density industrial 99% alumina ceramic boat crucible)

REQUEST A QUOTE

RELATED PRODUCTS

High 99 Al2o3 Zirconia Ceramic Alumina Boat With Lid

Combustion Alumina Ceramic Boat Crucible for Chemical Experiment

50*20*20 mm Heat Resistance Square Laboratory Alumina Ceramic Boat Crucible

High Temperature Resistant Refractory Ceramic Sagger Alumina Al2O3 Melting Ceramic Square Boat

High Purity Alumina Ceramic Square Boat Box Sagger and Crucible with Lid Refractory Product