Professional Premium Aluminum Oxide Products Supplier

1. Introduction

In a recent development reported by industry sources on June 24, 2024, global demand for high-purity alumina ceramics has surged—not only in aerospace and electronics but also in premium kitchenware. Consumers are increasingly seeking non-toxic, oven-safe, and long-lasting bakeware, driving interest in products like the alumina ceramic baking dish. This trend underscores a growing awareness of material safety and performance in everyday cookware.

Alumina (aluminum oxide, Al₂O₃) is a high-performance ceramic known for its hardness, thermal resistance, and chemical inertness. While industrial-grade alumina is used in crucibles, thermocouple tubes, and refractory bricks, food-grade alumina ceramics are engineered to meet strict safety standards for culinary use. This article explores the practical and aesthetic value of alumina ceramic kitchenware, with a focus on the alumina ceramic baking dish and related items.

2. What Is an Alumina Ceramic Baking Dish?

An alumina ceramic baking dish is a type of oven-safe cookware made from high-alumina-content ceramic. Unlike standard stoneware or porcelain, it contains a higher concentration of aluminum oxide, which enhances thermal shock resistance and mechanical strength. This makes it ideal for baking, roasting, and serving directly from oven to table.

These dishes are often marketed under terms like alumina baking ceramic dish or alumina oven ceramic dish. They maintain even heat distribution and resist cracking under rapid temperature changes—key advantages over conventional ceramic bakeware.

3. Common Types of Alumina Ceramic Kitchenware

Beyond baking dishes, alumina ceramics are used in a wide array of tableware and serving items. Popular variants include:

- alumina ceramic butter dish (often with lid for freshness)

- alumina ceramic casserole dish and alumina ceramic casserole with lid for slow cooking

- alumina ceramic serving bowls and alumina ceramic serving platter for elegant presentation

- alumina ceramic dinner plates, including alumina white ceramic plates and alumina black ceramic plates

- alumina ceramic childrens plates, valued for chip resistance and non-toxicity

- alumina ceramic ramekins and alumina salad ceramic bowl for portion control and salads

- alumina ceramic sugar dish and alumina ceramic plates for painting (used in decorative or craft applications)

- Seasonal items like alumina ceramic christmas plates and alumina christmas ceramic platter

These products combine functionality with minimalist or artisanal design, appealing to both home chefs and professional kitchens.

4. Performance Benefits in the Kitchen

Alumina ceramic dishes for oven use excel due to their high melting point (over 2,000°C) and low thermal expansion. This translates to exceptional performance in real-world cooking scenarios:

- Resists warping or cracking at high temperatures

- Safe for use in conventional, convection, and microwave ovens

- Non-reactive surface preserves food flavor and prevents leaching

- Easy to clean and often dishwasher-safe

Unlike metal bakeware, alumina ceramic does not conduct heat too rapidly, reducing the risk of burnt edges while ensuring thorough cooking.

5. Aesthetic and Design Versatility

Manufacturers offer alumina ceramic plates and bowls in various finishes, including glossy, matte, and handcrafted textures. Options like alumina handcrafted ceramic plates, alumina blue white porcelain plates, and alumina ceramic black plates cater to diverse interior styles.

The material’s natural whiteness allows for vibrant glazes, while unglazed variants showcase the raw elegance of high-purity ceramic. This flexibility makes alumina ceramic plate bowls and alumina ceramic bowl plates popular for both daily use and special occasions.

6. Clarifying Misconceptions: Kitchenware vs. Industrial Alumina

It’s important to distinguish food-grade alumina ceramic kitchenware from industrial alumina components. While keywords like alumina ceramic tubes, alumina crucible, alumina bricks, and alumina ceramic balls appear in technical contexts, they serve entirely different purposes.

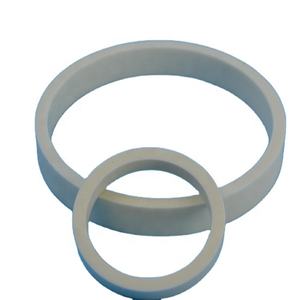

For example, alumina thermocouple protection tubes, alumina silicon carbide grinding discs, and alumina ceramic piping are engineered for extreme environments in metallurgy or laboratories—not for food contact. Similarly, alumina discs used in tap valves (e.g., alumina ceramic disc taps) are mechanical parts, not tableware.

Consumers should ensure any alumina ceramic dish labeled for kitchen use is certified food-safe and free from industrial additives.

7. Care and Longevity

To maximize the lifespan of an alumina ceramic baking dish or alumina oven dish ceramic, avoid sudden temperature shocks (e.g., placing a hot dish on a cold surface). Use non-abrasive cleaners to preserve glazes, and store carefully to prevent chipping.

With proper care, these items can last decades, making them a sustainable alternative to disposable or low-quality bakeware.

8. Availability and Brands

While niche, alumina ceramic kitchenware is increasingly available through specialty retailers and online platforms. Some premium brands, such as Staub, offer high-performance bakeware that may incorporate alumina-enhanced ceramics—though specific product lines should be verified for material composition (e.g., alumina baking dish staub).

Handmade options, including alumina ceramic plates for dinner and alumina ceramic serving dishes, are often sold by artisan potters emphasizing non-toxic, lead-free glazes.

9. Sustainability and Safety

Alumina ceramic is inert, non-porous (when properly glazed), and free from PFAS, PFOA, and other harmful chemicals common in non-stick coatings. Its durability reduces waste from frequent replacements, aligning with eco-conscious consumer values.

Certifications like FDA compliance or EU food-contact safety standards are key indicators of quality when purchasing alumina ceramic dishes for oven or table use.

10. Conclusion

The alumina ceramic baking dish represents the intersection of advanced materials science and practical kitchen design. From everyday alumina ceramic dinner plates to festive alumina christmas plates ceramic, this versatile material offers unmatched durability, safety, and style. As consumer demand for high-performance, non-toxic cookware grows, alumina-based ceramics are poised to become a staple in modern kitchens—distinct from, yet inspired by, their industrial counterparts.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as 10. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.