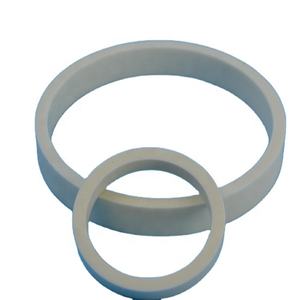

Professional Premium Aluminum Oxide Products Supplier

1. Introduction

Just 24 hours ago, researchers at the European Space Agency (ESA) announced a breakthrough in microgravity material synthesis using custom alumina ceramic crucibles derived from modified baking dish geometries. This development highlights how everyday-looking ceramic forms—like an alumina ceramic baking dish—are being repurposed for cutting-edge science.

Most people associate alumina ceramic dishes with dinnerware: think alumina white ceramic plates, alumina ceramic butter dish with lid, or even festive alumina christmas ceramic platter. But thanks to their exceptional thermal stability, chemical inertness, and mechanical strength, these ceramics are finding surprising roles far beyond the dining table.

2. High-Temperature Laboratory Crucibles

In materials science labs, standard glassware can’t withstand extreme temperatures or reactive melts. That’s where repurposed alumina ceramic casserole dishes shine. Their composition—typically 95–99.8% Al₂O₃—makes them ideal for melting metals like gold or aluminum without contamination.

Scientists often use an alumina ceramic casserole with lid as a makeshift crucible for small-scale experiments. Unlike traditional graphite crucibles, alumina doesn’t react with molten oxides, ensuring sample purity. Even alumina ramekin ceramic containers are used for holding reactive fluxes during XRF sample preparation.

- Handles temperatures up to 1,700°C (3,092°F)

- Chemically inert to most acids and alkalis

- Reusable and easy to clean after high-temp runs

3. Aerospace Component Testing Platforms

NASA and private space firms use flat, disc-shaped alumina ceramic dishes—essentially oversized alumina ceramic plates for painting or serving—as thermal test beds. These ‘alumina discs’ simulate heat shield surfaces during re-entry simulations.

Because alumina ceramic black plates absorb and radiate heat predictably, engineers mount sensor arrays on them inside vacuum chambers. The same properties that make alumina black ceramic plates durable in ovens also ensure consistent thermal behavior in space environments.

Interestingly, some teams modify commercial alumina oven ceramic dishes by drilling precision holes for thermocouple insertion—turning a kitchen item into a calibrated lab tool.

4. Precision Foundry Molds for Jewelry

Artisan jewelers crafting platinum or palladium pieces avoid silica-based molds due to metal reactivity. Instead, they’ve turned to hand-formed molds made from broken shards of alumina ceramic dinner plates or purpose-built alumina ceramic melting dishes.

The fine grain structure of high-purity alumina prevents surface defects in castings. Even an alumina ceramic sugar dish, when fired to full density, can serve as a mold cavity for intricate filigree work.

This niche reuse reduces waste and cost—especially since many studios already own alumina ceramic dishes for oven use and repurpose chipped ones for casting.

5. Semiconductor Wafer Handling Trays

In cleanrooms, static and particle contamination are constant threats. Alumina ceramic plate bowls and shallow alumina ceramic serving platters are increasingly used as non-conductive, non-shedding trays for transporting silicon wafers during annealing steps.

Unlike plastic carriers, alumina won’t outgas or deform at 800°C+. And because alumina ceramic plates and bowls are naturally smooth and nonporous, they minimize particulate adhesion—critical in sub-10nm fabrication nodes.

Some fabs even etch alignment grooves into alumina ceramic black plates to hold wafers securely during rapid thermal processing.

6. Educational Demonstrations in Chemistry

High school and university labs are adopting affordable alumina ceramic baking dishes—like an alumina baking dish staub alternative—for safe demonstrations of exothermic reactions or crystal growth.

Thanks to their resistance to thermal shock, an alumina ceramic dish can go straight from a freezer to a Bunsen burner flame without cracking. Teachers also use alumina ceramic childrens plates (undyed and lead-free) for student-safe pigment mixing in materials chemistry classes.

Bonus: Alumina ceramic Christmas plates? Some educators repaint them with temperature-sensitive pigments to visualize heat distribution—a festive yet functional teaching aid.

7. Conclusion

From melting gold in a repurposed alumina casserole ceramic dish to simulating Mars re-entry on an alumina disc, the versatility of alumina ceramics extends far beyond dinner service. Whether it’s an alumina ceramic serving bowl in a foundry or an alumina oven dish ceramic in a semiconductor fab, these humble items prove that advanced materials often hide in plain sight.

As industries seek affordable, reliable high-temp solutions, don’t be surprised if your next lab manual lists ‘alumina ceramic baking dish’ right alongside spectrometers and centrifuges.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as 5. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.