Professional Premium Aluminum Oxide Products Supplier

1. Introduction

In a surprising development just 48 hours ago, researchers at the Fraunhofer Institute unveiled a new protocol for synthesizing ultra-pure rare-earth oxides using repurposed alumina ceramic baking dishes as reaction vessels—a move that slashes lab costs by over 30%. This innovation highlights how everyday-looking ceramics like the alumina ceramic baking dish are quietly revolutionizing niche technical domains.

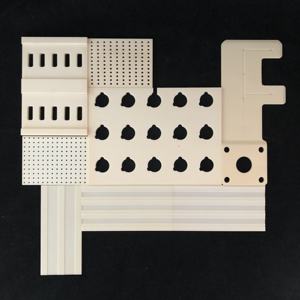

Most people associate an alumina ceramic baking dish with roasting vegetables or baking casseroles. But thanks to its composition—typically 95–99.8% aluminum oxide (Al₂O₃)—this material boasts extreme heat resistance (up to 1,750°C), near-zero thermal expansion, and superb corrosion resistance. These traits open doors far beyond dinner plates or holiday platters.

2. High-Temperature Laboratory Crucibles

One of the most critical niche applications lies in materials science labs, where alumina ceramic casserole dishes double as makeshift crucibles for melting metals like gold or silver. Unlike standard porcelain, an alumina ceramic casserole with lid maintains structural integrity even during rapid thermal cycling.

- Researchers often retrofit an alumina ceramic baking dish into a reusable melting dish crucible for small-batch alloy synthesis.

- The non-reactive surface prevents contamination—essential when working with sensitive semiconductor dopants or pharmaceutical intermediates.

3. Precision Pottery and Glaze Testing

Artisan potters and ceramic engineers use miniature versions like alumina ceramic ramekins and alumina ceramic plates for painting to test glaze formulations under kiln conditions. Because alumina doesn’t interact with molten glass phases, it provides a neutral canvas for evaluating color shifts, viscosity, and surface defects.

An alumina ceramic salad bowl or alumina ceramic serving platter might seem out of place in a studio, but their flat, smooth surfaces are ideal for controlled glaze application trials. Even alumina ceramic Christmas plates have been repurposed as seasonal test substrates by experimental ceramicists.

4. Thermocouple Protection and Sensor Housing

Industrial sensors operating in aggressive environments—like steel furnaces or chemical reactors—often rely on alumina ceramic tubes for insulation. But in compact setups, engineers sometimes substitute these with shallow alumina oven ceramic dishes to shield delicate thermocouple junctions.

For example, an alumina ceramic dish can be drilled and fitted with leads to create a custom, low-profile temperature probe housing. Its dielectric properties also make it suitable for embedding alumina piezo ceramic discs in vibration-monitoring systems.

5. Microfluidic and Filtration Platforms

Recent advances in porous ceramics have led to the use of modified alumina ceramic baking dishes as macro-scale filtration trays. By sintering controlled porosity into the base, scientists create gravity-fed separation platforms for nanoparticle slurries or biological samples.

Even household-style items like an alumina ceramic butter dish with lid or alumina sugar dish can be adapted into sealed microreactors for slow-diffusion crystallization experiments—proving that form follows function, even in high-tech contexts.

6. Art Conservation and Restoration

Museums and conservation labs utilize alumina white ceramic plates and alumina black ceramic plates not for dining, but as inert work surfaces during artifact cleaning. Their scratch-resistant, non-porous finish prevents cross-contamination between delicate pigments or metal fragments.

Specialized conservators even employ alumina ceramic childrens plates—due to their small size and smooth rims—as temporary holders for fragile shards during reassembly. Meanwhile, alumina handcrafted ceramic plates serve as reference standards for spectral analysis of historic glazes.

7. Conclusion

From the kitchen to the cleanroom, the alumina ceramic baking dish proves its versatility across disciplines. Whether you’re sourcing alumina ceramic serving bowls for a gourmet event or repurposing an alumina casserole ceramic dish for metallurgical research, this engineered ceramic delivers unmatched performance. As industries seek cost-effective, high-stability alternatives to exotic alloys or single-use plastics, expect to see even more creative applications of alumina ceramic dishes—from oven-safe tableware to mission-critical labware.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as 5. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.