Professional Premium Aluminum Oxide Products Supplier

1. Introduction

When you hear ‘alumina ceramic baking dish,’ your mind probably jumps to casseroles or holiday roasts. But this versatile material is quietly powering innovations far beyond the dinner table. Thanks to its exceptional heat resistance (up to 1,700°C), non-reactivity, and mechanical strength, alumina ceramic is a go-to in labs, studios, and factories worldwide.

In fact, many professionals repurpose standard-looking items—like an alumina ceramic casserole dish or alumina ramekin ceramic—to perform highly technical tasks. Let’s dive into five niche, real-world applications where these humble dishes shine.

2. High-Temperature Material Synthesis in Research Labs

Materials scientists often need containers that won’t contaminate samples during extreme heating. That’s where the alumina ceramic crucible—and its close cousin, the alumina ceramic melting dish—comes in.

Researchers use alumina ceramic casserole dishes with lids to synthesize novel ceramics, grow single crystals, or melt reactive metals like titanium. Unlike metal containers, alumina won’t leach impurities, ensuring sample purity.

- Alumina ceramic crucibles can withstand temperatures exceeding 1,600°C.

- The nonporous nature of high-purity alumina prevents gas diffusion during sensitive reactions.

- Even small-scale experiments benefit from repurposed alumina ceramic ramekins for precise batch processing.

3. Precision Glaze Testing in Artisan Pottery

Ceramic artists rely on consistency when developing custom glazes. Enter the alumina ceramic plates for painting—a blank, inert canvas that reveals true glaze behavior without interference.

Because alumina doesn’t react with most oxides or fluxes, potters use alumina white ceramic plates or alumina black ceramic plates to test color development, texture, and melt flow under kiln conditions.

Some even use alumina ceramic serving platters as large-format test tiles. The result? More predictable, vibrant finishes on final pieces like alumina blue white porcelain plates or handcrafted dinnerware.

- Alumina’s smooth surface mimics high-fired stoneware, offering realistic test results.

- Artists reuse the same alumina ceramic plate bowls for dozens of tests, thanks to their durability.

4. Controlled Atmosphere Food Science Experiments

Food technologists studying Maillard reactions, caramelization, or moisture retention sometimes require oven-safe vessels that don’t absorb flavors or release volatiles.

Here, the alumina ceramic baking dish proves ideal. Its thermal shock resistance allows rapid transitions from freezer to oven—critical for replicating commercial cooking processes.

Unlike traditional stoneware, alumina ceramic dishes for oven use maintain dimensional stability, ensuring consistent heat distribution across trials. Researchers have even used alumina ceramic butter dishes with lids to study lipid oxidation in controlled environments.

- Alumina oven ceramic dishes eliminate variables introduced by porous cookware.

- Their neutrality makes them perfect for sensory analysis panels testing flavor purity.

5. Holiday-Themed Calibration Tools in Industrial Ceramics

This one might surprise you: alumina Christmas plates ceramic aren’t just festive décor—they’re calibration aids.

In quality control labs for ceramic manufacturers, seasonal items like alumina ceramic Christmas plates or alumina Christmas ceramic platters are used as standardized test forms. Their complex shapes (curves, rims, handles) help evaluate glaze adhesion, warpage, and firing uniformity.

Because they’re made from the same high-alumina slip as technical components, these plates double as process validation tools—ensuring everything from alumina ceramic dinner plates to alumina ceramic serving bowls meets spec.

- Factories run holiday batches not just for sales, but for internal benchmarking.

- Defects visible on intricate designs reveal subtle kiln inconsistencies.

6. Supporting Roles in Advanced Component Manufacturing

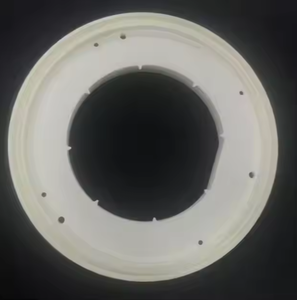

Even when not the star, alumina ceramic dishes play supporting roles. For instance, alumina discs and alumina ceramic grinding discs are used to polish surfaces of alumina ceramic tubes or bearings.

During assembly of alumina ceramic plumbing pipe systems, technicians place small parts on alumina ceramic plate bowls to prevent contamination. Similarly, alumina ceramic sanding discs help finish alumina silicon carbide bricks used in furnace linings.

And while not a dish per se, the principles are identical: purity, flatness, and heat tolerance matter—whether you’re crafting alumina ceramic childrens plates or alumina thermocouple protection tubes.

7. Conclusion

From the lab bench to the artist’s studio, the alumina ceramic baking dish is far more than kitchenware. Its unique blend of thermal resilience, chemical inertness, and mechanical reliability makes it a silent hero in niche technical fields.

So next time you see an alumina casserole ceramic dish or an alumina butter ceramic dish with lid, remember—it might just be destined for science, not supper.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as 5. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.