Professional Premium Aluminum Oxide Products Supplier

1. Introduction

In a recent development reported by Materials Today on June 14, 2024, researchers at the University of Sheffield unveiled a new high-purity alumina ceramic formulation that enhances thermal shock resistance by 22%—a breakthrough with immediate implications for premium kitchenware, including the increasingly popular alumina ceramic baking dish. This innovation underscores growing consumer demand for durable, non-toxic, and oven-safe cookware that performs reliably under extreme temperatures.

Alumina ceramic—composed primarily of aluminum oxide (Al₂O₃)—is prized for its exceptional hardness, chemical inertness, and ability to withstand temperatures exceeding 1,600°C. While often associated with industrial components like thermocouple protection tubes and crucibles, high-grade alumina ceramics are now making significant inroads into culinary applications, offering unmatched performance for home bakers and professional chefs alike.

2. What Is an Alumina Ceramic Baking Dish?

An alumina ceramic baking dish is a high-performance kitchen vessel crafted from dense, sintered alumina ceramic. Unlike conventional stoneware or porcelain, it exhibits superior thermal conductivity, minimal thermal expansion, and resistance to warping or cracking during rapid temperature changes. This makes it ideal for use in ovens, broilers, and even direct flame settings.

These dishes are commonly marketed under terms such as alumina baking ceramic dish or alumina oven ceramic dish, emphasizing their suitability for high-heat cooking. Their non-porous surface prevents flavor absorption and bacterial growth, ensuring food safety and easy cleaning.

3. Beyond Baking: The Full Range of Alumina Ceramic Tableware

The versatility of alumina ceramics extends far beyond baking. Manufacturers now produce a wide array of tableware, including:

- alumina ceramic dinner plates and alumina dinner ceramic plates, available in classic white (alumina white ceramic plates) or modern black (alumina black ceramic plates, alumina ceramic plates black)

- alumina ceramic serving bowls and alumina ceramic serving platter for elegant presentation

- alumina ceramic butter dish with lid and alumina butter dish ceramic with lid for fresh dairy storage

- alumina ceramic casserole with lid and alumina casserole ceramic dish for slow-cooked meals

- alumina salad ceramic bowl and alumina ceramic ramekins for individual portions

- alumina ceramic childrens plates, designed with durability and safety in mind

- alumina ceramic christmas plates and alumina christmas ceramic platter for seasonal dining

Notably, alumina ceramic plates for painting are also used by artisans, thanks to their smooth, receptive surface.

4. Industrial Alumina Components: A Parallel Universe

While alumina ceramic dishes for oven use dominate the culinary space, the same material serves critical roles in engineering and manufacturing. High-purity alumina is used to fabricate:

- alumina ceramic tubes for high temperature applications, including furnace linings and thermocouple protection

- alumina crucible and alumina ceramic crucible for melting metals like gold and steel

- alumina ceramic grinding disc and alumina diamond grinding disc for pottery and precision machining

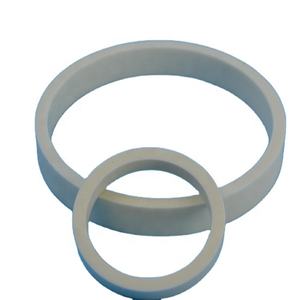

- alumina ceramic disc taps and alumina ceramic disk for tap in plumbing systems

- alumina bricks and alumina ceramic fire brick for kilns and industrial furnaces

- alumina ceramic balls and alumina ceramic bearing for wear-resistant mechanical systems

These industrial products share the same core properties—extreme hardness, thermal stability, and corrosion resistance—that make alumina ceramic baking dishes so effective in the kitchen.

5. Why Choose Alumina Over Traditional Ceramics?

Compared to standard ceramic or porcelain bakeware, alumina ceramic dishes offer several advantages:

- Higher thermal shock resistance reduces breakage during sudden temperature shifts

- Non-reactive surface preserves food flavor and prevents leaching of metals or glazes

- Exceptional durability ensures longevity, even with daily use

- Oven-safe up to 1,400°F (760°C), far exceeding the limits of most glass or stoneware

Brands like Staub have begun incorporating alumina-enhanced ceramics into premium lines, sometimes referenced as alumina baking dish staub, though true high-alumina content remains a hallmark of specialized manufacturers.

6. Care and Maintenance Tips

To maximize the lifespan of your alumina ceramic dish or alumina ceramic plates and bowls:

- Avoid sudden immersion in cold water after high-heat use

- Use non-abrasive cleaners to preserve the glaze

- Store carefully to prevent chipping, though alumina is significantly harder than standard ceramics

- Hand-washing is recommended, though many alumina ceramic items are dishwasher-safe

These simple practices ensure your alumina ceramic casserole, butter dish, or dinner plates remain pristine for years.

7. Conclusion

The alumina ceramic baking dish represents the convergence of advanced materials science and everyday kitchen utility. From robust alumina ceramic dishes for oven use to elegant alumina ceramic serving dishes and even industrial-grade alumina tubes and crucibles, this material delivers unmatched performance across domains. As innovations like those from the University of Sheffield continue to enhance alumina’s properties, consumers can expect even more durable, efficient, and versatile ceramic products in the near future.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as 7. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.